Since the PWI held its first electrification seminar in 2018, the event has become increasingly popular. As reported in issue 196 (May-June 2022), last year’s Scottish seminar focused on the Scottish electrification programme and initiatives for cost reduction.

This year’s seminar ‘Electrification – into the future’ was held in Sheffield. It also considered electrification’s affordability as well as power supplies, third rail and Ireland. It was a fascinating day.

As he welcomed delegates, PWI President Peter Dearman stressed the need for affordable electrification to get schemes authorised to achieve net zero carbon emissions, especially as the Treasury’s economic evaluation does not consider electrification’s full benefits. He recommended that delegates study the ‘Rail Electrification – the facts’ leaflet that is available from the Railway Industry Association (RIA) website.

Drive down costs

In his keynote address, Rob McIntosh, managing director of Network Rail’s Eastern Region stressed that the railway faced the opposing dynamics of its 2050 net zero commitment and unprecedented pressure on the public purse for which brilliant engineering needs to drive down costs. He has a copy of the ECML electrification project’s close out report as a reminder of what can be achieved.

He also recalled the excitement in 2008 about plans to electrify the whole network and how we then lost our way and had to cut back parts of Great Western electrification. He stressed that this must never happen again. Although delivering affordable electrification is a huge challenge, he was convinced that the industry can drive down unit rates of electrification. Whilst Midland Main Line (MML) and Transpennine Route Upgrade (TPU) rates are good, these are not enough, and costs must be further reduced.

Better clienting

Lisa Webb is Network Rail’s Eastern Regions’ principal portfolio manager for Capital Delivery. She stressed that electrification delivery is only a small part of the total programme costs. She said that to reduce these huge indirect costs needs a significant change in the way we mobilise and interact with the environment around us.

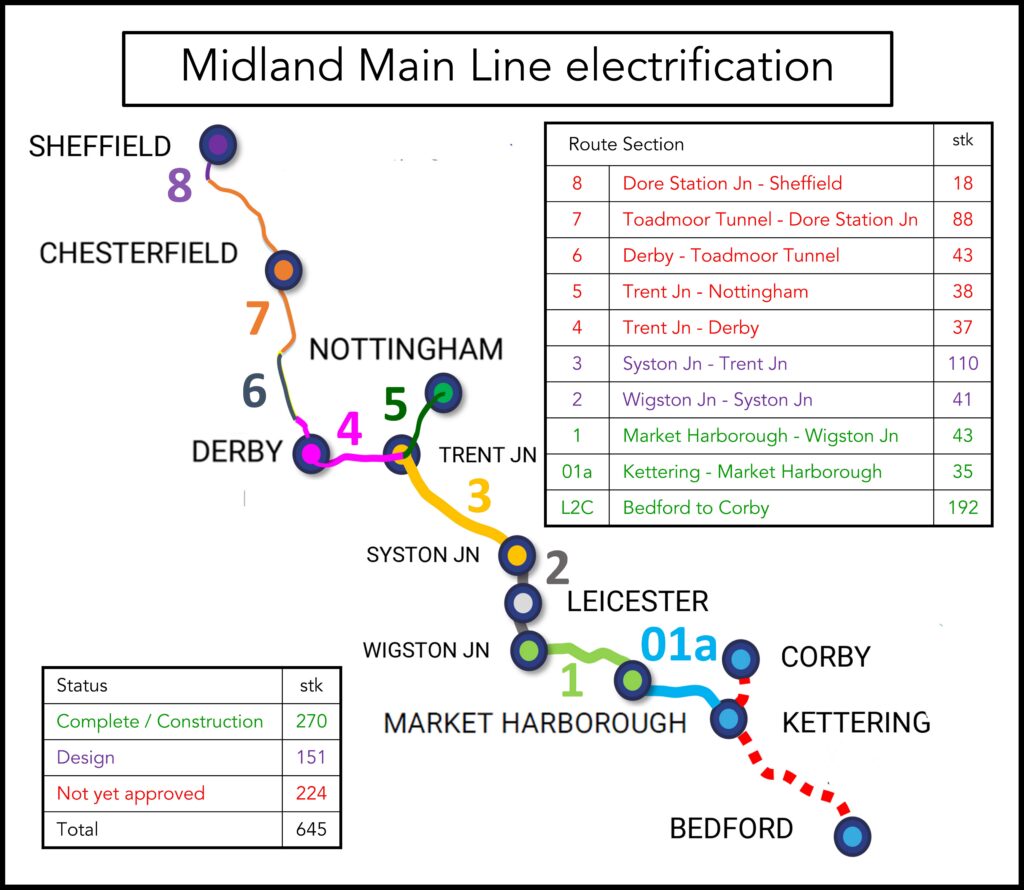

She considered how Network Rail is supporting the supply chain by becoming a better client for the Midland Main Line (MML) electrification programme of which 130km of its 330 route km has already been electrified. Work to Wigston, just south of Leicester has been authorised as has a £500 million programme to upgrade the London to Bedford overhead line for 125mph running. However, uncertainty remains about the approval of electrifying the remaining 137 route km.

For Lisa, the lessons of previous schemes were painfully obvious. We make things too difficult, change our minds, don’t know enough about our existing assets, and do too much rework. Learning from this requires certainty, reducing complexity through standardisation, optimising production and deconflicting different work packages, optimising scarce resources, and a relentless focus on cost.

She advised that as the MML programme is not driven by a timetable change, there is flexibility to minimise costs by deconflicting the key elements of route clearance, immunisation, and electrification.

As a client, her job is to manage uncertainties and optimise the critical track access for maximum productivity. The procurement strategy also must ensure work is done collaboratively and efficiently.

She referred to the project SPEED initiative which has reduced bureaucracy and gives teams permission to challenge and be creative, giving everyone a role in achieving the desperately needed cost savings. As an example, reducing the option selection from one year to three months saved £250 million. There are also constructive discussions between Network Rail and the Department for Transport (DfT) to reduce the huge amount of duplicated effort.

Lisa was convinced that with the right focus and leadership we really can do things differently. She concluded by advising that we must all ask ourselves what we can do to ensure our success.

Delivering electrification

SPL Powerlines’ Regional Director for England & Wales, Steve McWhan, and Engineering Director, Simon Skinner explained their company’s approach to the electrification cost challenge.

Steve described initiatives which included a wiring unit that can install a complete wire run in a short nightshift possession, stillages to avoid wasting possession time supplying materials, pre-dressed steelwork and the use of gantries and rails instead of cranes to install sub-station building.

Simon considered the need for discipline integration which requires awareness of the needs of others. He stressed that each discipline’s signed off assurance documentation must be done in real time rather than just before authorisation. He also felt that only quality assured metrics should be counted. He advised that SPL had a metrics dashboard which indicates the health of a project.

Steve said that successful projects, such as the Bedford to Corby electrification, all had a shared team vision with everyone taking decisions that were right for the project. He was amused at the idea of using a contract to make people work together. He said he knew that didn’t work as it was people working together that formed a team. He feels that the industry contract award process is essentially about blame and liability when the requirement should be to take on board risk and reward performance.

He noted that the biggest ever programmes were delivered at an affordable price in the 1980s and early 1990s and so offered a lot of the answers. Then, experts and gangs specialised in specific aspects, had a factory production mentality, and strove for continuous improvement. This is difficult to achieve with projects continuously starting and stopping which makes training problematic.

Eastern’s power strategy

Network Rail’s Tom Ingrey, a lead strategic planner and Kaitlyn Mair, principal traction power design engineer, considered the development of regional traction power strategies. Tom noted that there were 32 electric trains when the East Coast Main Line (ECML) was first electrified and now there are 85, and that introducing these new trains had not considered power supply constraints.

This illustrated the need for a power supply strategy to take a long-term view of all factors affecting demand. This helps make the business case, manage the power supply investment pipeline, addresses the requirements of the electricity supply industry (ESI), and ensures stakeholders understand power supply constraints.

It is also important for power supply investment to consider maintenance. Furthermore, power supplies are particularly sensitive to the additional electrified freight services needed to meet freight growth targets.

Tom feels that understanding the impact of timetable changes on the power supply needs a proactive approach with power supply modelling for new train fleets, electrified freight, and further electrification. In the long term, the traction power strategy needs to be assessed on a collaborative basis by all concerned including the ESI which has many other customers wanting more power. Tom advised that the Eastern Region has 46 electrification power supply points. To meet the forecast demand, 15 needed to be upgraded and a further 35 or so supplies are needed.

Kaitlyn Mair advised that the traditional approach of determining power supply requirement from the exact timetable, rolling stock details, and power supply arrangements didn’t work as situations change. There were two main questions: i) How much power is needed; and ii) Where can this power come from?

For the first question, the Eastern route was broken down into 222 segments with 14 generic timetables developed to assess their load per kilometre. This analysis considered that battery trains had double the power of an electric train and used long term planning data to 2050.

Answering the second question needed a review of open-source data to consider the available capacity and proximity (within 5km) of high voltage power lines to the railway as well as land availability. If there is no viable connection, possible alternatives are embedded generation and lineside storage.

Design considerations require primary routes to have a direct ESI connection whilst secondary routes may be fed from primary routes; the use of autotransformers for high power routes; 12kA fault levels and a maximum 100km round trip for a battery EMU. Feeder station capacity ranges from 10 – 100 MVA and feeding distance ranges from 25- 60km.

This analysis showed where new and upgraded substations are required and provided a strategic output showing power demand increase up to 2050 for various electrification options, including the programme for a net zero carbon railway in Network Rail’s Traction Decarbonisation Network Strategy (TDNS) which increases the Eastern Region power demand from 554MVA to 1,697MVA.

For Kaitlyn, an interesting aspect of this study is that even the lowest electrification option predicted a power demand of 1,200MVA, which is over twice the current capacity.

WCML power problems

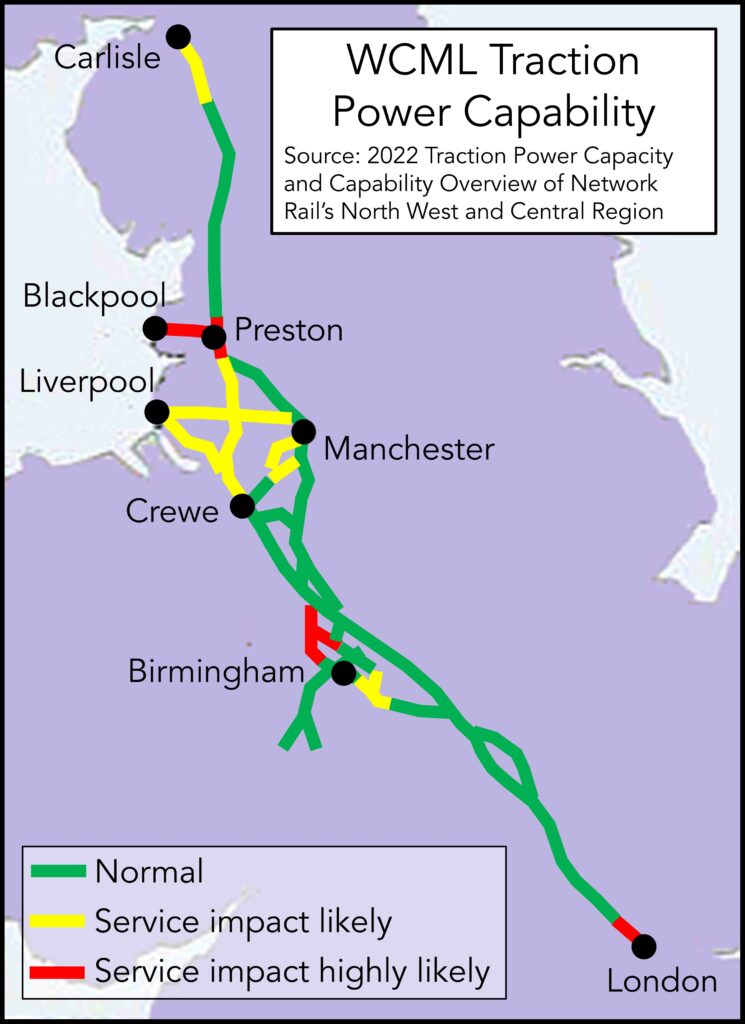

Dean Chauke, Network Rail’s E&P engineer for its North West and Central Route, presented a frank assessment of the significant power supply problems on much of the West Coast Main Line (WCML). These include Rugby to Wolverhampton via Birmingham, Crewe to Manchester and Liverpool, and Preston to Carnforth. For example, if the Trent Valley route is blocked, there is insufficient power supply to feed the WCML service via Birmingham. Network Rail is also declaring the WCML south of Carlisle to be congested infrastructure due to power supply constraints.

As well as additional electric trains in recent years, there are more to come including the Avanti Class 805 units and the new Class 93 and 99 electric freight locomotives. Furthermore, freight paths are made available without considering if they need electric power.

Currently, much of the WCML electrical supply system is at maximum capacity and subject to overloads which can cause major incidents of up to 10,000 delay minutes. For example, an overloaded feeder outside London required the closure of all four tracks for 10 minutes at a cost of circa £1 million. Frequent short outages also present a significant maintenance workload as switchgear oil must be filtered and refilled every 30 operations.

The WCML Traction Power and Capability Overview concludes that there are likely to be service affecting issues on the lines to Blackpool, through Wolverhampton and between Crewe and Preston. Dean advised that these constraints were due to large parts of the WCML having classic booster transformer electrification and that proposals to provide autotransformer system for the complete route were discussed decades ago and still hadn’t been delivered.

Power electronics

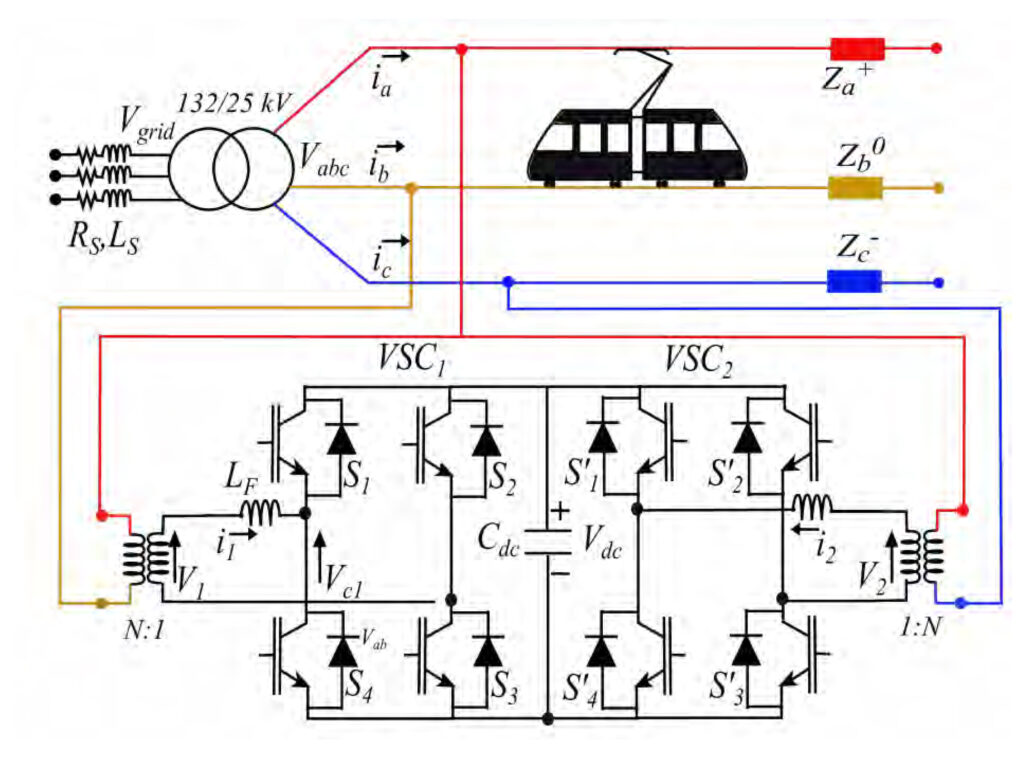

Dr Tabish Mir, assistant professor with the Power Electronics, Machines and Control Research Group at the University of Nottingham explained her research on power electronics which she considered to be a key technology for railway decarbonisation.

Currently, the sections of OLE between feeder stations are fed from a single phase of the high voltage national grid with adjacent sections fed from a different phase which requires neutral sections between each section. This results in grid current unbalance from unequal phase loading and reactive power loading from autotransformers.

Her research considers mitigating this unbalance by Power Electronics Autotransformers (PEAT). These could enable feeder stations to take a three-phase supply from the grid with an intelligently controlled PEAT connected between two different phase pairs to compensate for the single-phase train load.

She also considered how power electronics could take advantage of the reserve capacity of feeder stations for electric vehicle charging. A battery bank would be provided to ensure continuity of charging when the feeder station was fully loaded.

Third rail developments

Nigel Wheeler, senior E&P programme manager of Network Rail’s Southern Region explained third rail DC electrification system developments in respect of electrical safety and decarbonisation.

The installation of Negative Short Circuit Devices (NSCD) which are operated from a place of safety, provides safety and productivity improvements as they eliminate the need for personnel to go on the track to fix short circuiting straps to the third rail when taking isolations. Currently around 50% of the third rail network has NSCDs and the plan is to achieve full coverage by the end of CP7.

Nigel explained the incremental approach taken by the roll out programme which installed NSCDs during renewals and is also developing this technology with the aim of the electrical control room controlling all isolations whilst those on site have a lock out app.

For decarbonisation, the aim is to obtain low cost, net zero carbon electrical power and replace diesel traction. As well as getting power from the grid, the Southern Region is progressing power purchase agreements for either remote generation fed from the grid or local generation with a direct connection to Network Rail’s HV system.

To progress this, a scheme was successfully implemented at Aldershot to feed energy from solar panels into the traction supply. With a 30kW output, this was a small proof of concept scheme, for which it is easier to get funding.

Options to eliminate diesel traction depend on the type of service. As well as battery and hydrogen traction, one option is twenty-first century third rail electrification for which the conductor rail in stations is switched off unless a train is present. This is being discussed with the ORR as a possible decarbonisation solution for the unelectrified 40km Uckfield branch.

With Southern carrying a third of UK passenger trains, Nigel advised that the third rail is here to stay but needs to be made better.

Carbon accounting

Samuel Seabrooke, Rail Sustainability Lead Overhead Contract System Engineer at Mott MacDonald advised that 97% of Network Rail’s emissions are from its customers and suppliers. Of these, 63% are from built and bought items. Hence Network Rail requires its suppliers to have a robust emission reduction plan by 2025 and that all projects over £1 million must undertake a capital carbon assessment.

He stressed that switching traction power to electricity doesn’t eliminate emissions as embodied carbon has to be considered. His presentation shows that the carbon payback for a two train per hour electrified railway is 28 years. This compares with an assessment in RIA’s ‘Why Rail Electrification’ report of an average of four year carbon payback for the full TDNS electrification programme.

He queried whether it is acceptable to build schemes with a break-even carbon payback years into the future. He explained the carbon impact of each stage of a project and advised that reducing embodied carbon required an understanding of what to capture and when, as well as the availability and quality of data and its usage, and that the identification of carbon hotspots was particularly important.

Decarbonising Irish Rail

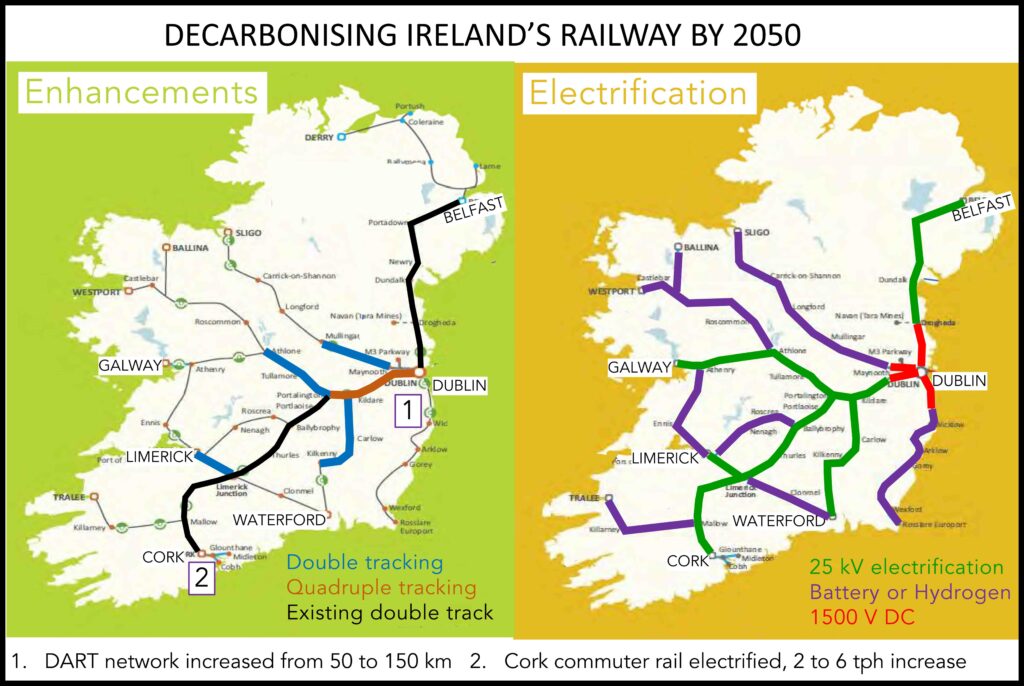

Irish Rail’s director of Capital Investments, Paul Hendrick described Ireland’s plan to decarbonise its railway which is primarily a radial system from Dublin which is single track except for Cork-Dublin-Belfast.

Of Irish Rail’s 2,200km network, only the 50km Dublin Area Rapid Transit (DART) network is electrified with a 1,500 V DC overhead line system. There is now a €3 billion programme to increase the DRAT’s passenger capacity from 26,000 to 52,000 per hour. This will expand its electrified network to 150km and procure up to 750 electric/ battery electric vehicles, the first of which will be delivered next year.

In Cork, there are plans to increase service frequency from two to six trains per hour by 2040. The suburban network is to be electrified and double tracked with new electric trains at a cost of €1 billion. There are also plans to transform the cross-border Dublin to Belfast service for which train procurement is scheduled to commence next year.

By 2050 it is intended that all city-to-city lines will have been electrified at 25kV AC, although options for 25kV trains running over the 1.5kV DC network have yet to be determined.

The total indicative investment for Irish Rail is €20 billion, for which plans will be developed further in an all-Ireland Rail Study which will be published later this year.

Freight decarbonisation

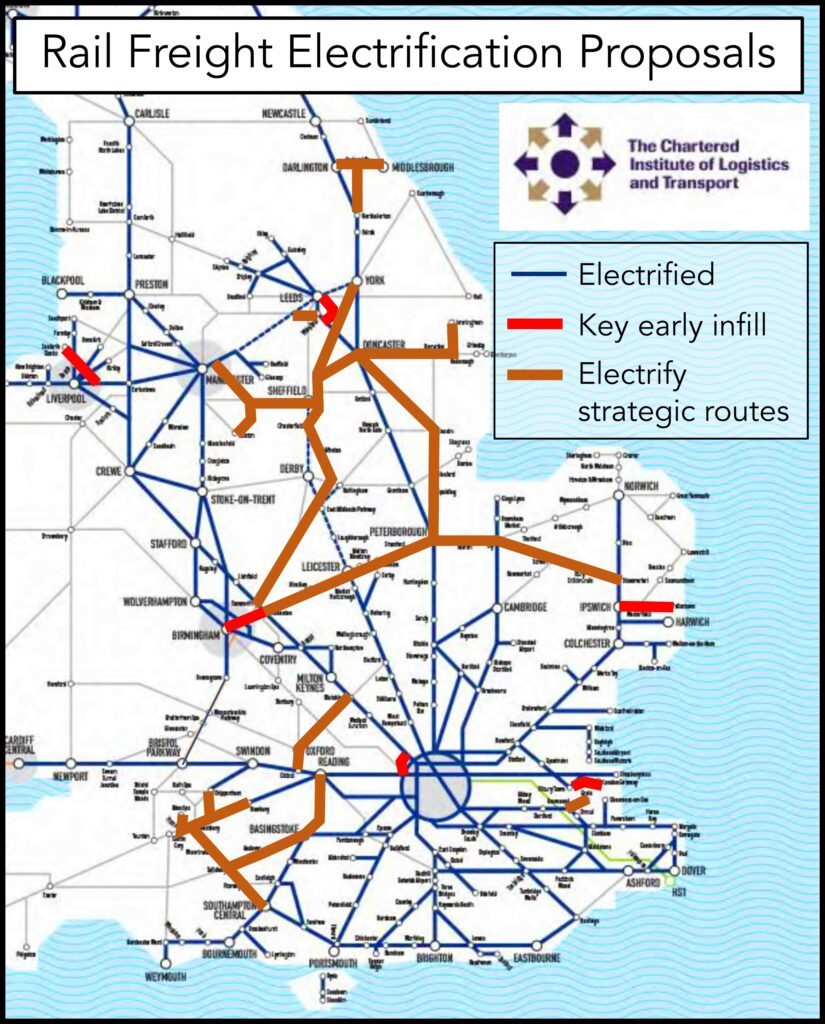

Julian Worth, Chair of the Chartered Institute of Logistics and Transport (CILT)’s Rail Freight Forum, stressed that rail freight matters. It has the biggest rail traffic growth potential, strong decarbonisation benefits, and provides a strong business case for electrification. Moreover, there is currently no credible decarbonisation alternative for long distance HGV traffic. He considered that this would produce a new multi modal logistic model of long-haul rail with local distribution by battery truck. He considered that there was potential for a third of road freight to switch to rail.

Of the 3,200km core rail freight network, two thirds is already electrified. A further 1,300 route km of electrification would enable 95% of freight to be electrically hauled. He noted that this was a much smaller ask of the DfT and Treasury than the 13,000 stk TDNS programme.

In a recently published report, the CILT identified six short routes totalling less than 100km that would give an additional two million electric train miles. However, Julian stressed that electrification of even such short key routes is a non-starter if electrification costs are £2.5 million per stk and that costs had to be below £1 million per stk to convince the Treasury.

He believes that this is achievable by maximising efficiencies and rooting out overheads. Unless the industry could demonstrate value for money there would be no more wires.

Making the case

The PWI’s electrification seminar in Sheffield was a sell-out event with some having to stand in the auditorium. Its presentations offered a fresh perspective and were well received. The key message stressed throughout the event was the need to reduce costs, both of actual delivery and of overheads which are greater than delivery costs.

It also provided a fascinating insight into power supplies and why a whole system approach is needed to match supply and demand, as illustrated by the WCML power supply problems. Third rail, an often overlooked aspect of electrification despite powering a third of UK passenger trains, was also well covered. It was also good to hear of the ambitious plans to electrify and decarbonise the railways of Ireland.

From the presentations and discussions in the breaks, it was clear that the industry has the capability to deliver the electrification programme required to improve and decarbonise the rail network. Yet the authorisation of further such programmes depends on the Treasury being confident that the industry can deliver affordable electrification as well as explaining the benefits of electrification.

Although the desire and capability to deliver cost-effective electrification was evident at the Sheffield event, making the case remains a significant challenge. It is to be hoped that the Sheffield conference helped in this respect.