The previous article examined whole life costing of rolling stock on the main line railway as discussed at a late-2023 IMechE Railway Division Seminar. Present at the same event were several speakers from Transport for London (TfL) who presented their asset planning processes and case studies on planning rolling stock overhaul and replacement. Theirs is a challenging environment, where the demands of trying to keep the assets in a good state of repair exceeds the finance available.

Planning

TfL has huge asset requirements over many modes of transport. London Overground and the Elizabeth line lease their rolling stock but, with an exception on one line, London Underground (LU) owns its fleet. It relies on funding and/or permission from the government to buy train fleets. For many years, the significant benefits arising from capacity upgrades justified fleet (and signalling, power, etc.) renewal/upgrades. Where assets were near the end of their lives, the benefits of more capacity dwarfed the benefits of any other options such as life extension. More recently, money for capital projects has been in short supply whilst assets continue to degrade, so TfL had to return to justifying fleet major overhauls and renewals on their own merits.

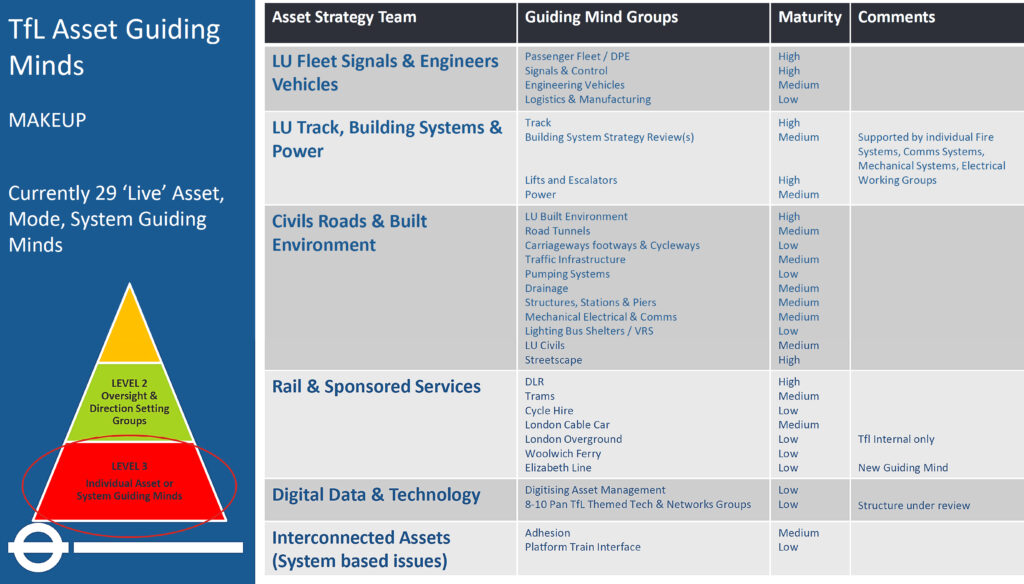

Howard Taylor, TfL’s principal asset strategy manager, introduced the concept of the Asset Guiding Mind (AGM). The AGM comprises key business functions:

- Asset Strategy: setting the long-term strategies, objectives, and investment plans for each asset group.

- Asset Operations and Maintenance: delivering day-to-day safe operations.

- Engineering: setting technical standards and policies, providing assurance, approval, and professional advice.

- Each asset area has a guiding mind group, whose output is integrated into overall advice to top management.

Helen Cooper, asset strategy manager for interconnected assets, described how this works in practice. The groups develop outcome-based, whole-life asset strategies including costed and scoped long-term asset plans, models and risks, and technical strategies (from Engineering). These become the focal point for prioritising short to medium-term maintenance and investment proposals.

The whole life approach is developed taking account of life, condition, duty, obsolescence, legislation, and changes in customer expectations. The AGM group acts as the voice for the asset group, becoming the focal point for consulting on asset issues, and is seen as the ‘one stop shop’ for understanding asset risk and direction.

In an ideal world, these groups’ recommendations would lead to interventions when needed, but, Howard reported, “we don’t live in an optimal whole life world.” Currently TfL’s capital funding is considerably less than necessary for steady state renewals/investment levels, with future funding still uncertain. This has led to constant pressure to reduce operating costs, creating consequences and risks in supporting current and future levels of service. In this environment, TfL has to use available information to tackle the most urgent renewals/significant risks. The guiding mind team also develop asset plans for a range of financially constrained scenarios while evaluating asset risks and consequences that need managing and escalating. Helen’s own area – rolling stock – comprises approximately 4,000 cars in 600 trains ranging in age from 11 to 50 years, the oldest of which are likely to be at least 20 years beyond their originally planned 36-year life by the earliest date that replacements could be in service.

Repair or replace?

Andrew Meeson and Lorena Naylor, both lead sponsors in TfL’s Investment Delivery Planning team, outlined the cases for investment in Bakerloo line trains and a small fleet of battery locomotives, respectively. As already described the Bakerloo line trains are around 50 years old but the battery locomotives are even older.

The Bakerloo line is the last of LU’s main lines to receive an upgrade to its capacity. It was included in the Deep Tube Upgrade Programme which let a contract with Siemens for a new Piccadilly line fleet with time limited options for the Bakerloo, Central and Waterloo, and City line. Since the Covid pandemic, it has not been possible to exercise any of the options due to the capital finance constraint already mentioned. However, the 1972 tube stock is the oldest fleet in regular passenger service in the UK and cannot be expected to remain in service without significant expenditure.

TfL has developed three scenarios: ‘Do Nothing’, ‘Do Minimum’ (and defer replacement), and ‘Replace Straight Away’. Already the service has been reduced from 22 trains per hour to 20 and TfL forecasts this decline will continue until the service has to be stopped within about 10-15 years if there is no further work to manage the trains’ condition (Do Nothing).

The Do Minimum option proposes £200 million for life extension works, £350 million to deal with obsolescence issues, and higher than new train maintenance costs at £750 million. The obsolescence estimate is uncertain and independent studies suggest this cost could be more than double TfL’s £350 million estimate. Moreover, this option only delays the expenditure on new trains. The Replace Straight Away course of action involves exercising the contract option for new trains; probably the firmest estimate as it is based on the contract price.

Andrew said that by not replacing the fleet there is a risk that the cost of a new fleet is incurred anyway through continuing to keep the 1972 tube stock in service, without resolving the underlying risks nor realising the benefits of a new fleet. If the time limited contract option can’t be exercised, a new procurement process would be required setting back the replacement of the fleet until the mid-2030s at the earliest. Whole life cost is better with replacement under the existing contract option and provides better value for money than decline or deferred replacement.

Out of sight

Lorena described a somewhat harder challenge. TfL’s fleet of 29 tube gauge battery locomotives was built between 1964 and 1973 to a much earlier design. All used 1930s traction motors with the oldest using second hand bogies, some of which should have celebrated their 100th birthday. The locomotive maintainers have sometimes had to ‘borrow’ parts from exhibits in the London Transport Museum to keep them running. These are vehicles that customers rarely see, but they rely on them as they haul wagons that deliver heavy materials, particularly rail, sleepers, and ballast, and haul plant to enable track renewal and other heavy jobs. They run when power is removed, hence battery operation, and in order to operate over all lines, they need at least four different signalling systems.

Lorena said that availability and reliability are suffering due to ageing and obsolete components and that there are more and more problems (such as structural defects and bogie cracks), with only 17 of 29 are currently available for use. Shortage of locomotives impacts on the ability to undertake track works across the entire LU network and overdue track work could lead to imposing speed limits or even closing parts of the network. She added that a project to replace the locos will be complicated and is expected to take up to 10 years.

Key questions to answer in building the business case included:

- How many years might the existing locomotives stay in service and how much might it cost?

- How many locomotives are needed to support expected track and other work?

- How do the methods of carrying out that work impact on that number?

- Are there innovations that enable maintenance activities to be more efficient? (With changes in travel patterns since Covid it is possible that weekend closures for heavy track work might become even more unpopular needing new access arrangements to be agreed.)

These are interconnected questions. Each one is complex and has a range of options, and the cost estimate for each is likely to be far from firm.

As for innovations, unless track components become significantly lighter, Rail Engineer suspects that there will be a continuing need for locomotives and wagons for decades to come. As a member of the audience observed, LU has been exploring new designs locomotives and innovations such as fixed formation, distributed traction trains for over 40 years, yet the elderly locomotives soldier on.

Lorena said next steps will explore similar options to those considered for the Bakerloo line fleet including keeping the existing vehicles in service for another 20 years. She added that TfL expects the cost of maintaining the existing locomotives will be less than the cost of replacements, so the business case will have to demonstrate that whole life costs and the significant risk of locomotive unavailability, making it impossible to carry out vital maintenance work make the case, offsets the upfront cost of new locomotives.

Overhaul

Even TfL’s newest Underground trains are over 10 years old and are due for heavy maintenance. Chris Moss, Daniel Hamblin, and Hugh Torry discussed their work optimising the scope of programme lift (bogie overhaul) and heavy overhaul (bogies, bodies, and equipment) on the 2009 Victoria line trains (47 trains, 376 cars) and the S stock used on the District, Circle, Hammersmith & City, and Metropolitan lines (59, 8-car and 133 7-car trains, 1,402 cars). Maintenance requirements were determined during design, and the engineering team worked to understand the factors driving maintenance and try to minimise the number of times trains are stopped for heavy maintenance.

Heavy maintenance was originally scheduled every 762,000km, or seven major interventions during the fleet’s life. Using service experience, TfL’s engineers and many of the original equipment suppliers worked together to assess the condition of equipment that was due to be maintained at the first 762,000km intervention. TfL aims for only three interventions at roughly 1.5 million km intervals followed by scrapping at circa 6 million km. It managed to integrate 2009 stock underframe and bogie work from a whole host of different interventions to just two at 1 million km (trailer cars) and 1.2 million km (motor cars).

Engineers were optimistic that they would be able to further extend to 1.4 million km. Using similar techniques, the engineering team were able to extend bogie overhaul on S stock from 762,000km to 1.25 million km, extend brakes and pneumatics overhaul from 1.143 million km and, to make a package, bring forward gearbox overhaul and flexible bogie frame bush replacement from 1.524 million km. Daniel added that this aligns well with forecast wheel life for S8 trains.

S stock is a big fleet, with a very large inventory of parts, and it was reported that a saving of £20 million on the original S stock overhaul estimate had been achieved. TfL expects to make further changes to the maintenance requirement and there was confidence that £300 million might be saved over the life of the trains.

Conclusion

TfL has the challenge of competing for scarce public funds to replace increasingly old and frail assets on the Bakerloo line, and for maintaining the railway. Currently it is only the London Transport Museum that runs occasional heritage trains on the Underground network. Rail Engineer hopes that TfL obtains its settlement with the government so that heritage operations don’t become a day-to-day feature.

TfL expressed the issue in stark terms in its recent paper to the Programmes and Investment Committee: “There are significant daily challenges to keep the fleet available for service. If the fleet is not replaced, there would be an increasing risk that an endemic failure could force the withdrawal of its 1972 tube stock from operation.”

Rail Engineer does not envy TfL’s engineers having to manage the risks and uncertainties running a busy service using trains that are so far beyond their design lives.

Photos and captions by the speakers and the writer unless otherwise shown.