Pre-Covid, there were almost 300 million journeys a year on Britain’s light rail systems. Their high capacity provides urban connectivity that drives economic growth. For example, the Docklands Light Railway helped regenerate London’s Docklands whilst Manchester’s Metrolink was the catalyst for Salford’s Media City. Unlike buses, trams attract motorists from their cars and so reduce congestion and emissions.

Yet Britain has only nine light rail systems compared with 28 in France and 57 in Germany. In Europe, towns with populations less than 50,000 can support a tram system, whilst Leeds – with a population of 800,000 – has the distinction of being Europe’s largest city without one. Over the last 70 years, Britain has invested 40% less on transport than the rest of Europe. With increasing recognition of the need to reduce urban car use, more light rail systems are required. Yet conventional tram systems typically cost around £50 million per kilometre, with a 1.7km extension of a Birmingham tram line costing £160 million. At these prices, providing a number of medium-sized cities with a light rail network is quite simply unaffordable.

However, in 2017, one such city, Coventry (population 320,000), decided that it should be able to afford a suitably specified light rail system as part of its transport strategy when the City Council approved a plan to develop a Very Light Rail (VLR) network. One reason for this decision is that the city has significant exceedances of air pollution limits and light rail does not have the non-tailpipe emissions from brake pads and tyres that buses have.

Since then, the City Council has been working with the University of Warwick’s WMG (Warwick Manufacturing Group) to develop a VLR system at a target cost of £10 million per kilometre.

Innovative track and vehicle

To achieve this target cost, a shuttle-type vehicle has been adopted which uses lightweighting techniques developed by WMG, has no overhead catenary, requires minimal utility diversions and reduces the earthworks required. WMG has partnered with Transport Design International to design the prototype vehicle which is being built by NP Aerospace in Coventry and is now almost complete. This prototype is self-powered from a 750V 54kWh battery that gives a range of 70km. An out and back journey will consume about 9kWh. The intention is that the battery can be charged overnight from a 20kW supply and during the day receive 3.5-minute rapid charging from a 200kW supply. Packaged underfloor is the electronics and the lithium titanate battery which has a safe chemistry.

The vehicle is made from steel, aluminium and composites, with a carbon/polyethylene bumper and carbon/Kevlar cab ends. Polycarbonate windows meet the requirements of the post-Croydon accident recommendations. It has a maximum speed of 70kph and can tackle a 5% gradient. All axles are driven and an innovative bogie enables the network to have 15-metre radius curves. A future vision is autonomous driving which would significantly reduce operational costs and offer a greater load factor.

The production vehicles weigh 11 tonnes, are expected to cost around £750,000 each and normally carry 50 passengers or 70 in crush conditions when their weight will be 16.5 tonnes, giving them a maximum four-tonne axle weight.

Vehicles carrying 50 passenger with a typical four-minute headway would transport 750 people per hour. This is about a third that of the Edinburgh tram system which carries 250 people at seven-minute headways.

The VLR system can only be affordable with a new trackform that can be installed at an acceptable rate and at low cost, in particular by avoiding the need for utility diversions. It must also not be damaged by heavy road traffic and accommodate 15-metre radius curves. To develop such a track, WMG has partnered with the Paris-based engineering group INGEROP and its British consultancy, Rendel.

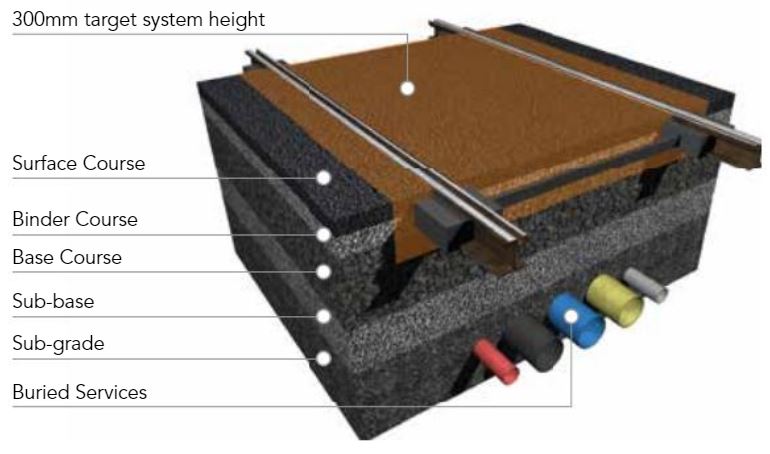

The anticipated cost of the developed trackform is £2 million per kilometre, including excavation of the road surface and embedding the track into it. It is expected to be installed at a rate of 16 metres per day. As it is only 300mm thick, the track can be installed without disturbing utilities installed at a minimum depth of 450mm.

However, installing the VLR track over services will only be acceptable to utility companies if they can treat the track as a normal road. Hence the trackform can accommodate 600 x 600mm utility access chambers and, in an emergency, can be dug out and replaced in 24 hours. The track has been designed to support high loads on a low-stiffness subgrade of 2.3% CBR (California Bearing Ratio). The CBR is typically 5-50% for sandy soils and only 2% for clay.

Bringing it all together

However good the design of the vehicle and new trackform, extensive testing of both – as a system – will be required before work starts to install the Coventry VLR system. In addition to design optimisation, this will be required to obtain the required approvals. This testing is to be done at the VLR National Innovation Centre (VLRNIC) at Dudley which is currently under construction.

Rail Engineer was keen to learn more so was glad of an opportunity to tour the centre with the Railway Industry Association (RIA)’s Technical and Innovation Manager, Sam Bemment. RIA is keen to promote this emerging industry and has done so at various events including a recent five-day online Unlocking Innovation event, ‘Light Weight and Low-Cost Railway’ (see Issue 188 Jan/Feb 2021). Our visit was hosted by Richard Jones, Business and Partnership Manager for BCIMO (Black Country Innovative Manufacturing Organisation) which has been set up to oversee the VLRNIC’s build, launch and operation.

Richard explained the centre’s purpose is not just to test the VLR system, but to create a whole new industry. The aim is to showcase this new technology and work with Local Authorities to create jobs by developing a VLR supply chain. In addition, the centre’s facilities are now available for conventional rolling stock and infrastructure testing. For example, the DfT recently used its 867-metre tunnel to test 5G communications in railway tunnels. During our visit, Birmingham City University was using it to investigate laser surveying techniques.

The Centre is being built on the site of Dudley Station which closed in 1962 and was replaced by a Freightliner terminal in 1967. This, in turn, was closed in 1987, with the line through Dudley closed to all traffic in 1993. The land for the centre has been leased from Network Rail for 40 years on condition that the freight line through it can be reinstated if necessary. An 11km extension of the West Midlands Metro from Wednesbury to Brierley Hill will run close to the centre and is expected to open in 2024.

Nearby is the Black Country Living Museum whose webpage quotes Elihu Burritt, American Consul to Birmingham in 1868, as saying “The Black Country, black by day and red by night, cannot be matched for vast and varied production by any other space of equal radius on the surface of the globe.” Hence Richard wishes to see VLRNIC recreate an industry here, though without 19th Century pollution. The construction of the Black Country and Marches Institute of Technology immediately adjacent to the centre will help in this respect. Richard expects VLRNIC to be training about 900 students from the college over the next three years to show them opportunities in the rail industry at trades level. Hence various items of railway infrastructure are to be installed on spare land between the centre and college.

VLRNIC

The main Dudley VLRNIC facility has a footprint of approximately 250 x 50 metres. This comprises a workshop building, a storeroom, vehicle shed, car park and the northern end of its test track. On its west side, the cutting has been excavated and a large retaining wall provided to accommodate the workshop. The Brierley Hill Metro extension will run just behind the top of this retaining wall and will have a stop, Dudley Castle, next to the VLRNIC.

The test track is a 2.2km standard gauge single line built to 100mph standards, with a 15-metre radius turnaround loop adjacent to the main facility. It will have platforms at main line and tram stop heights. 250 metres south of the main facility, this track enters the double-track tunnel which will be lit and with a walkway provided on the unused trackbed. There is sufficient space adjacent to this test track to install the new VLR trackform.

The main workshop building will have 4,600m2 of floor space across three floors. Its roof will be fully covered by photovoltaic cells which will generate 98MWh per year. This will feed a battery farm and hydrogen electrolysis plant. The main workshop is the full height of the building and has a 10-tonne overhead crane. It has two roads – one is the length of the workshop and the other is a through road which extends outside to a concrete pad for the delivery and removal of rail vehicles. Both roads have 15-metre-long pits and share the use of four 16-tonne lifting jacks.

On the western side of the workshop, three floors of rooms will contain an electric power train dynamometer system, electronic and software laboratories, a control centre and a driver simulation suite which can also be used for route analysis. Richard advises that there will also be plenty of space for co-location with SMEs and for collaborative R&D projects. In addition, on the second floor there will be a 100-seat auditorium and exhibition centre with a balcony overlooking the test track which will provide a good opportunity to showcase VLR and other vehicles under test. This will provide an ideal venue for local companies to launch their products.

The completed 36 x 10 metres vehicle shed enables vehicles to be tested prior to completion of the main building. It has one road with an 8-metre pit, a 1.4-tonne overhead crane and four 16-tonne jacks. During our visit, the centre’s Zephir Crab 1500 E shunting tractor was seen in this shed. This is a small vehicle of 2.2 x 1.8 x 1.5 metres (LxWxH) weighing four tonnes, with rubber-coated rail wheels that has a 300-tonne towing capacity.

The budget for VLRNIC construction is £28 million which includes £16 million for the main building, £8 million for the trackwork and £4 million for the retaining wall. Funding has been provided by Dudley Council, the Black Country Local Enterprise Partnership and the Government’s Getting Building Fund. In addition, Coventry Council paid for the cost of the retaining wall.

The main construction work is by Clegg Construction whilst Trackwork is installing the railway infrastructure. Richard points out that the ORR has granted VLRNIC exemption from the Railways and Other Guided Transport Systems (Safety) Regulations.

The centre is expected to be fully open in May 2022.

Instant charge

VLRNIC was in the news in April when Furrer+Frey installed the world’s first VLR ultra-rapid battery charging station. The company installed its first such charger for battery buses in 2010 in Granada and they are now used in Sweden, Spain and the Netherlands. The charger at Dudley has software developed by Furrer+Frey UK specifically for VLR vehicles.

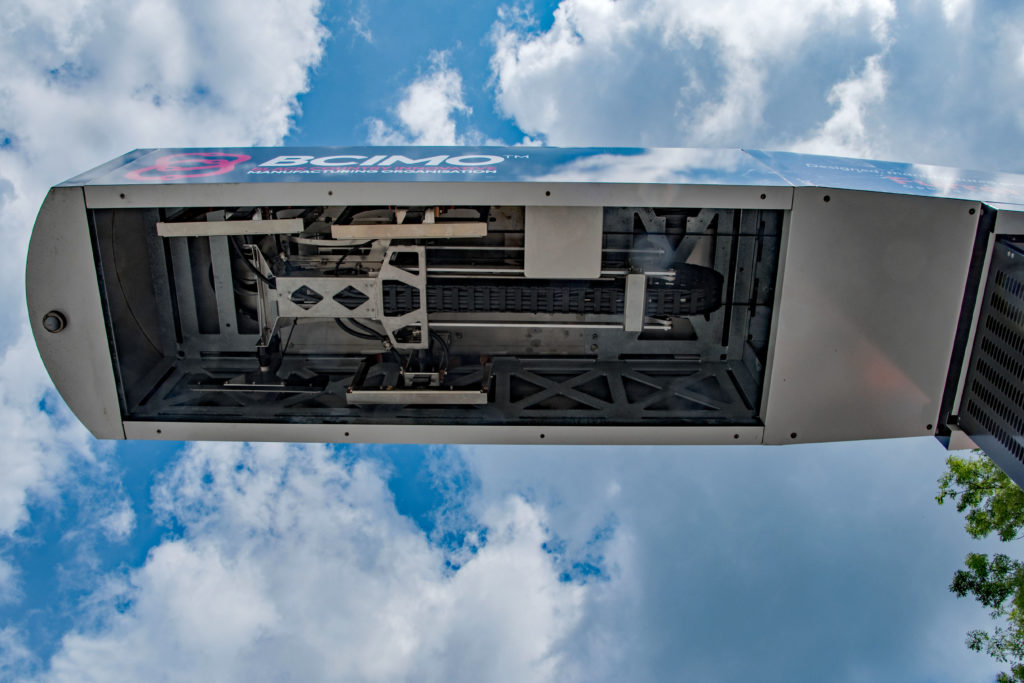

The charging station essentially contains an inverted retractable pantograph. Once the VLR vehicle is in place, the charge station operates autonomously as it communicates with the vehicle to confirm it is safe to lower its charging arm and then starts to charge the battery within five seconds, with no operator involvement. The arm has four contact strips specially designed for high-power transfer. Once the vehicle is charged, the arm retracts to a safe de-energised state.

As previously mentioned, it is expected that charging the VLR vehicles will require a 200kW supply for 3.5 minutes. The unit has been shown to charge at 900A. Its maximum capacity is 450kW.

Looking to the future

With the construction of the VLRNIC and its adjacent technical college, together with the planned West Midlands Metro, Dudley is about to see big changes.

When the centre is operational, it is expected to employ around 40 personnel. Richard believes it will create other employment as the VLR supply chain is developed, and local SMEs and the adjacent collage are able to benefit from its facilities. Although VLRNIC will not be fully open until next year, it will soon see some significant developments: the prototype VLR vehicle by September and some of the trackform should be laid by October.

Richard considers that around 40 cities could benefit from a VLR network and advises that “we are talking to many of them”. Although he is currently unable to say who he has been talking to, this will become clear on 30 September when it is planned to have a launch event in Dudley at which eight or nine cities are likely to be represented, together with housing developers and potential suppliers. The intention is that a VLR user group will be formed at this event. In this way VLRNIC will be bringing together technical development, the market and the supply chain.

The Holy Grail is a VLR system whose capital and operating cost is so low that it will attract private finance so that Councils will not need to call on the public purse. If this happens, the goal of significantly increasing the number of cities with light rail systems becomes feasible.

Yet, for it to happen, it needs to be demonstrated that VLR’s hardware can work in practice and be provided at the anticipated cost. VLRNIC has a key role in this respect. Moreover, with a driver needed for each 50-person vehicle – compared with one for each 250-person conventional tram – autonomous operation is needed if VLR systems are to become widely affordable.

With advances in artificial intelligence and autonomous systems, it is possible to envisage a remote operator who controls multiple vehicles and intervenes when alerted to problem situations. VLRNIC will no doubt be actively involved developing this concept, though it is unlikely that this technology will be approved for use before Coventry’s planned introduction of its VLR system in 2025.

Richard Jones is clearly enthused at the prospect of VLRNIC driving the development of VLR systems. He sees this to be an opportunity to work effectively at system level and get there first to set standards. As well as providing affordable urban transport on a large scale, he is aware of international interest that could lead to significant exports. All this is, as he says, a huge opportunity.