Since 2005, the Rail Accident Investigation Board (RAIB) has investigated around 50 freight derailments and other accidents such as track damage from wheel flats. The main or contributary cause of almost all these accidents was poor wagon condition. This included deterioration of suspension components, uneven loading, brake defects, handbrakes left on, and severe wheel flats, either due to brake faults or long wheel slides in low adhesion conditions. Had it been possible to detect such problems as they occurred, most of these derailments would have been prevented.

When such derailments occur, there is the potential to foul other lines to cause a potentially catastrophic passenger train derailment. Fortunately, there have been no such accidents in recent years. The cost of freight train derailments is high. Two recent derailments which resulted in piled up 100-tonne wagons were those at Llangennoch (issue 194 Jan-Feb 2022) and Petteril Bridge Junction (issue 205 Nov-Dec 2023). The recovery bill for these two accidents alone is likely to have been of the order of £50 million.

Our report on the Petteril Bridge Junction derailment included a pilot scheme to develop technology that can detect wagon faults to prevent freight train derailments. This is the iWagon which is being developed by the VTG freight wagon leasing company with the support of Knorr-Bremse.

Developing the idea

To learn more, Rail Engineer was glad of the opportunity to speak to Nigel Day, VTG’s business improvement director. When he was the company’s engineering director, he had been convinced for some time of the need for a wagon fitted with suitable state-of-the-art monitoring equipment. However, for VTG the business case for this was not financially viable, despite it offering a very rapid payback for the whole railway system.

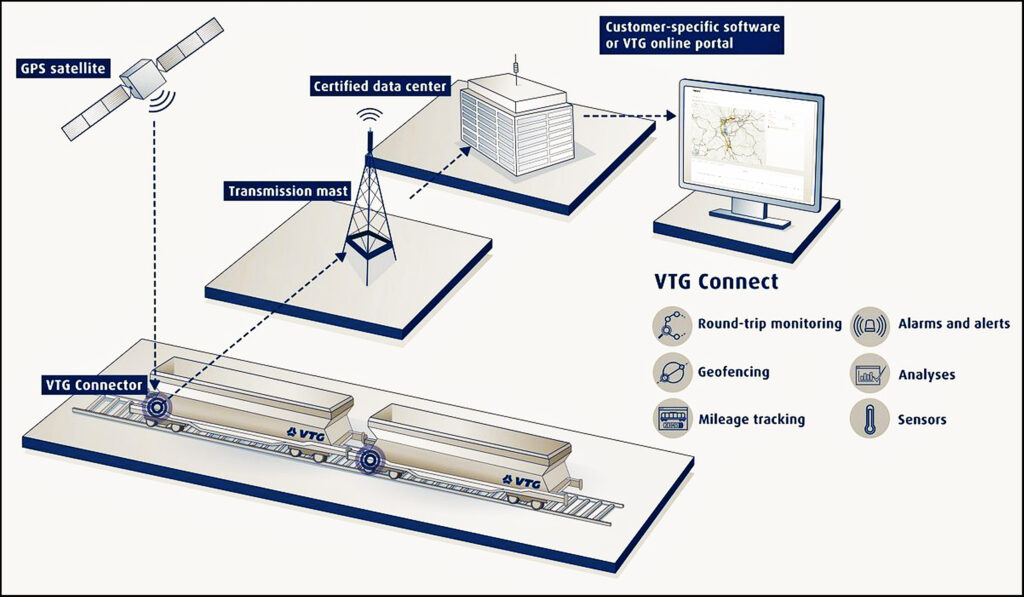

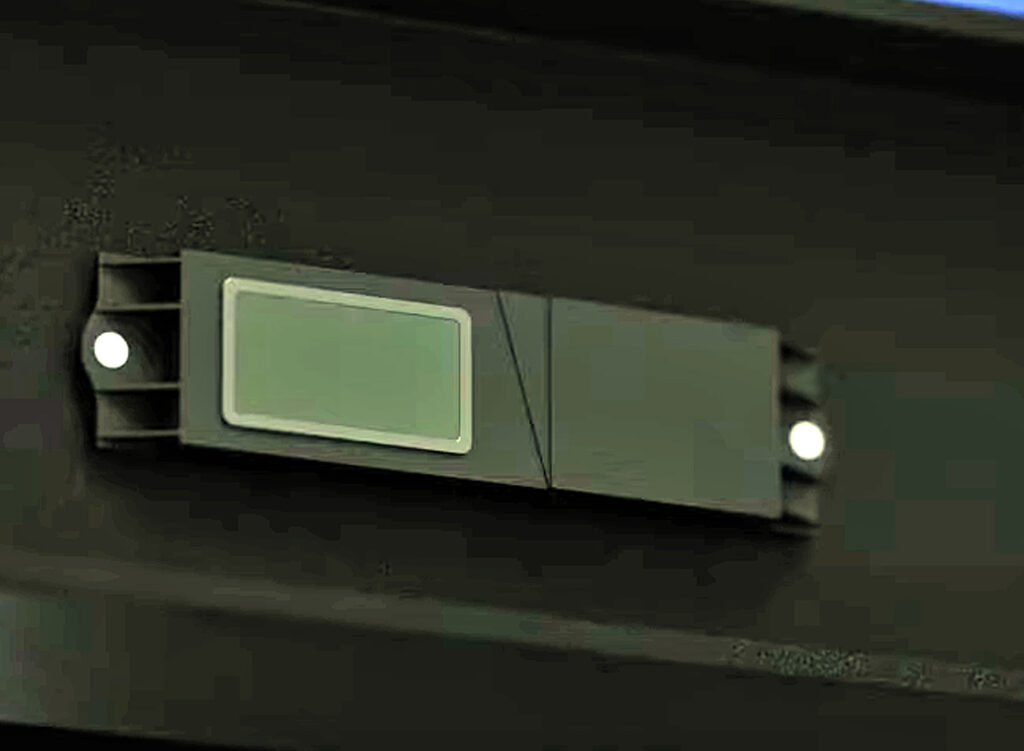

Nevertheless, VTG considered that there was a strategic business case for its ‘iWagon’ as this was considered to be something that its customers would want. The company also wished to show that it offered technologically advanced wagons. The iWagon initiative would also build on the VTG Connect system that the company had been fitting to its wagons since 2017. This was solar-powered and provided customers with wagon shock, GPS, and mileage data.

Amongst other things, VTG Connect has been used to identify where, along its journey, a wagon was graffitied. This was done by analysing its journey to determine where it was stationary for extended periods of time to show where security measures needed to be tightened up.

To develop the iWagon, VTG signed a partnership deal with Knorr-Bremse. Nigel advises that his opposite number in Knorr Bremse, Director of Engineering and Innovation Sanjay Albert, led the development of the iWagon’s bespoke processing unit and managed the provision of Knorr-Bremse equipment.

The system is made up of the following components: 4 x axle end generators per wagon; Wheel Flat Prevention system (WFP – a form of wheelslide protection); vibration sensors; pressure transducers; GPS unit; data transmission module; and the bespoke processing unit. A clever aspect of the axle generators is that they also detect axle speed, so the WFP does not require a separate speed detection system as is the case with Wheel Slide Protection systems on passenger rolling stock.

iWagon data is transmitted by mobile data to a cloud server from where it can be monitored anywhere by VTG and wagon operators. The train driver can also pick up alerts from this server. As a backup for areas of poor mobile reception, the system also uses Bluetooth-like connectivity to daisy chain iWagon data down the train to the driver. However, this requires the train to have a reasonable number of iWagons as the daisy chain is broken if there are more than four other wagons coupled together.

VTG has developed an app for the driver which provides an alert in the event of a locked wheel or brake problem and advises which wagon is defective. As each Freight Operating Company (FOC) has its own driver advisory app, it is not feasible to integrate these with the driver’s iWagon app which the driver only needs in the event of a rare defect.

Pilot scheme

iWagon was launched at the Rail Freight Group’s annual conference in October. The first phase of a nine-wagon iWagon pilot scheme began at the same time. The first three wagons to be fitted were 100-tonne cement wagons that were modified at Tarmac’s Dunbar depot. These operate a daily service between Dunbar in Scotland and Seaham in County Durham. The other wagons trialled were on the Mendip quarry services and between Clitheroe and Mossend, the route used by the freight train that derailed at Petteril Bridge junction.

The technologies on test include axle lock detection, the WFP system which also monitored wheelslide, and brake condition monitoring. Future trials will assess digital real-time maintenance, and monitor harmonics frequencies and temperature.

On the first day of the trials, everyone was surprised at just how slippery the rails were as almost every time a train stopped, it slid to a stop. Nigel confessed that he hadn’t realised how slippery the railway can be.

On the initial trials, an iWagon was marshalled between two monitoring wagons to provide a comparison of wheelset condition. Between 18-24 October these wagons made four journeys from Dunbar to Leeds, Aberdeen, and Inverness covering 748 miles. Due to significant wheel slides on the monitoring wagons, including one of a kilometre immediately south of Aberdeen, this trial was cut short as the monitoring wagons had significant wheel flats and needed new wheels. The iWagon had no wheel damage and thus proved the system.

An important aspect of this trial is assessing how data from it can be used. VTG has engaged the Swedish company, Predge (Predictive Edge) whose products include maintenance data analytics for the heavy Swedish iron ore trains. Predge is a machine learning specialist which is providing VTG with algorithms to analyse condition data in real time to optimise predictive maintenance. Nigel considers that the trials are showing the value of such big data management to the extent that it significantly improves VTG’s own business case for the iWagon.

A potential problem identified on these trials is that the wagon brake might run out of air if the WFP makes multiple continuous air dumps to prevent wheel slide. Most UK wagon fleets operate with a single-pipe system which both charges the brake cylinder reservoir air and applies the brake in accordance with a pressure reduction in the pipe. Unlike a two-pipe system, a single pipe cannot simultaneously apply the brake and charge the air reservoir. Although the trials showed that the WFP emptying the brake reservoir was an unlikely risk, the system has an alarm which would alert the driver to stop the train should this happen.

Performance data from this trial is being monitored from VTG’s Bromsgrove office. By the end of January sufficient data will be available to configure the first batch of production iWagons, the first of which is expected to be completed in July.

Benefits

As well as preventing derailments, iWagon offers many benefits which include the prevention of flats. On freight wagons, wheel flats are a common occurrence. With, say, a 25-tonne axle load the resultant impact of every wheel rotation causes infrastructure deterioration and occasional broken rails. Hence there is a case for reduced track access charges for flat-free iWagons.

If a lineside detector records an impact load of greater than 350kN from a wheel flat, the train is taken out of service and the FOC is liable for the resultant delay attribution.

An additional benefit from the elimination of flats is that this dramatically reduces the number of shunting moves needed to extract defective wagons from a train. As most freight trains are now block trains, such shunting moves are a significant proportion of the total.

iWagons also have the potential to transform wagon maintenance and preparation. As well as detecting whether a handbrake has been left on, brake pressure data from wagons at the front and back of the train in effect offers a brake continuity test provided that the train consist is known. VTG has created a programme to extract train consist information from TOPS. Nigel advises that interacting with the TOPS system in this way was really challenging.

Total Operations Processing System (TOPS)

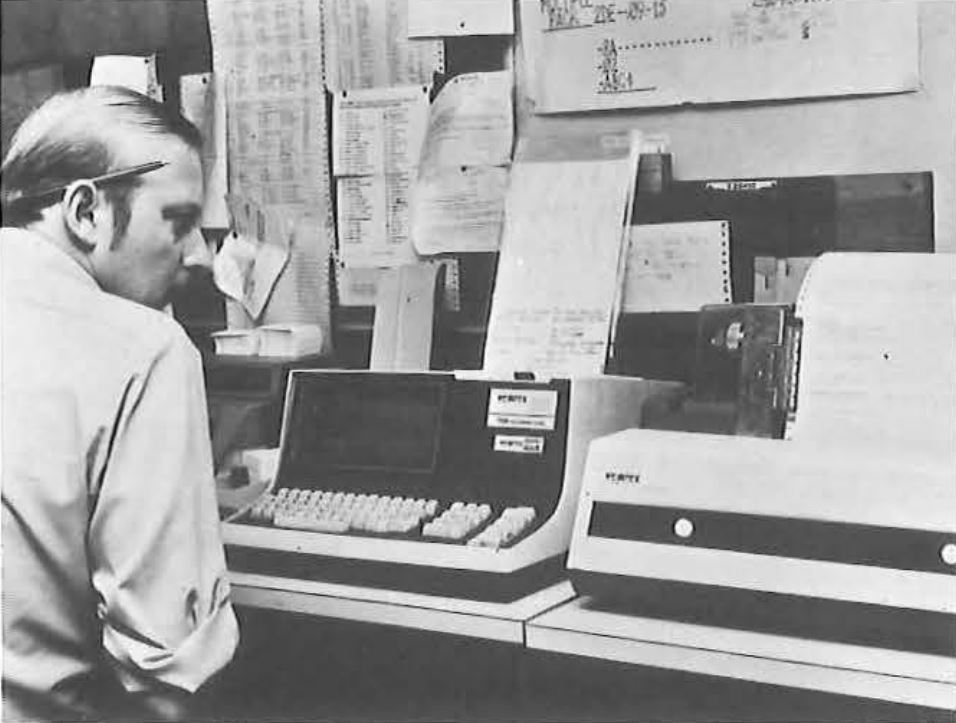

In the early 1970s, British Rail purchased the TOPS system from the American Southern Pacific Railroad to improve the efficiency of its freight operations. Prior to TOPS, your writer had the daily job of phoning all concerned to produce a report on the status and location of the Scottish locomotive fleet at 06:00. This took over an hour.

This changed with the implementation of TOPS which holds the locations and status of all locomotives and wagons and train consists. It is written in its own programming language, TOPSTRAN and originally ran on an IBM mainframe computer. Its implementation in 1973 and 1974 required the provision of hundreds of computer terminals in depots, freight yards, etc. This was the first widespread use of computers on British Rail and required a major cultural change.

Fifty-years later, this text-based system is still an essential part of UK railway operations. For historic data analysis or use with other applications, bespoke TOPS data extraction programmes are required such as the one developed by VTG.

The feasibility of harmonic frequency analysis to detect broken springs, cracked bogie frames, and other defects is to be assessed at the next stage of iWagon development. As each component has its own natural frequency, a wagon has a spectrum of, say, 10 standard frequencies. A change to a frequency associated with a particular component indicates that it has a defect.

Nigel considers that the combination of such frequency analysis with iWagon’s brake system monitoring and other technologies, such as data analytics and digital wheelset measuring, has the potential to significantly reduce wagon maintenance to the extent that this might be reduced to just changing brake blocks and wheels. This could offer significant availability benefits.

A further benefit is the detection of unevenly loaded wagons that have caused derailments. This is done by data analysis of the pressure in the wagons’ variable load valves to detect trends in the way customers load their wagons.

Finally for Network Rail, the iWagon provides real time monitoring of adhesion condition on lines served by freight trains to better identify low adhesion hot spots and make best use of rail head treatment trains.

Roll out

VTG owns about 4,500 wagons which are about a third of the UK wagon fleet. Its first batch of production iWagons enter service around July. Towards the end of the year, the plan is to ramp up iWagon production to 1,000 per year.

The iWagon system is currently being tested on wagons with integral braking. These have bogie-mounted brake cylinders that directly press the brake blocks onto each wheel and comprise the vast majority of the VTG fleet. Its suitability for wagons with non-integral braking systems has yet to be demonstrated. Such wagons have a single brake cylinder on the wagon underframe with a rigging system to press their multiple brake blocks against the wheels. Hence, their braking is less responsive than that of a wagon with integral braking due to unavoidable slack in their brake rigging.

Lessons for innovation

The iWagon has potentially transformational safety and commercial benefits.

As well as preventing freight train derailments, it eradicates damaged wheels and offers reduced shunting and track maintenance costs, improved wagon availability, and improved rail adhesion monitoring. In its report into the Petteril Bridge junction derailment, RAIB concluded that “there was no engineered system in place to detect wheelsets that were not rotating.” iWagon provides such a system.

These are huge benefits. Yet for the organisation funding it, iWagon had a poor business case. The rail industry is fortunate that VTG’s decision to invest in the iWagon was not based on immediate direct financial returns. This raises the question of how a company can be incentivised to invest in a new technology that can clearly benefit the wider industry. Current arrangement to promote rail innovation do not seem to address this issue.

It is certainly true that there is no shortage of grants for rail innovation, yet VTG chose not to seek such grants. When asked why, Nigel advised that applying for such grants took too long and that they generally only support small pilot schemes. Hence the use of current innovation competitions and grant schemes would have significantly constrained VTG’s iWagon deployment.

Nigel also believes that successful rail innovation needs to be incremental. He cites the proposal to fit freight wagons with autocouplers. This would be a whole system innovation requiring commitment from all FOCs and the modification of all freight locomotives to provide a freight train with an electrical supply. Thus, if this was to happen, it would take many years.

In contrast, iWagon is a wagon solution rather than a train solution. It can function by itself and be coupled to other wagons in the train. Furthermore, its basic functional package with an electrical supply and data transmission enables its functionality to be incrementally expanded. As well as harmonic frequency wagon analysis, temperature sensors and reversing cameras have been suggested for the next steps.

Thus, VTG and Knorr-Bremse have developed their transformational iWagon despite the current industry structure and industry innovation arrangements. For this, Nigel Day of VTG, Sanjay Albert of Knorr-Bremse, and their teams deserve to be congratulated.

Image credit: VTG / RAIB / British Rail