In Rail Engineer 200 (Jan/Feb 2023), an article about poor comfort of modern trains concluded that ride quality is a system property and not determined by the train alone. In July, the IMechE held a ride comfort seminar with presentation from train, track, system, and Transport Focus experts. With humans coming in all sorts of shapes and sizes with a variety of opinions, this is a complex multi-dimensional problem involving human perception.

Passengers

Ian Wright from Transport Focus and Neil Bates from Creactive Design Transport (CDT) outlined comfort from the passenger’s point of view. There’s more to it than just the seat, vehicle movement, and noise. Ian reported that a passenger’s fifth-highest priority was getting a seat – much more important than getting a comfortable seat (16th). This was taken as an approximation for ride comfort, acknowledging that both factors become more important with older passengers. He explained that passengers’ priorities vary depending on time of travel with off-peak only travellers likely to be less familiar/confident about train travel.

Case study

MerseyTravel commissioned Transport Focus’s passenger research group to help make the interior of its new trains appealing to Merseyside residents. Ian explained how prospective passengers identified what they liked (comfortable bay seating) and disliked (narrow blocked aisles, lack of storage space and longitudinal seat, like those on the London Underground). Customers said they appreciate having seats close to doors, expressed a desire for open wide gangways, but dislike people blocking doorways. The new Liverpool trains (Class 777) have tip up seats providing flexibility, bike spaces, wheelchair spaces, and, crucially, level access from platform to train.

It’s not all about seats

More generally, Ian questioned the recent drive for more and more seats. It is really more about the battle for the limited space represented by the available floor area of the train, he said. Legislation has mandated space for wheelchairs, but is it unreasonable for a family to be able to keep a buggy with them adjacent to their seats? And what about enough space for luggage? And has the legislation for wheelchair spaces kept up with the demand and nature of the wheelchairs themselves?

Neil Bates suggested that the design of trains should start much earlier than is usually the case, saying that the train design is part of the brand and not just a canvas on which to apply it. He showed a Design Council methodology adding that train design usually starts at the ‘plan’ stage – halfway through the process. The seat is one of the most important ‘interfaces’ on the train.

Passenger preference and barriers they identify include: (i) legroom – seat pitch and free-space between in-line seat backs; (ii) shoulder space – how much free space between seat centres; (iii) seat angles and geometry – appropriate for length of journey; (iv) lumbar support – its location, extent and integration; and (v) seat space (for bay seats with tables).

In another journal, CDT has said: “The industry has largely failed to grasp the importance of passenger experience, which should be at the centre of how trains, stations, and amenities are designed. Railways should work with passengers and do so early”. This was the case with Liverpool’s Class 777s.

Bridget Eickhoff from RSSB described the challenge of specifying and assessing ride comfort, which depends on both vehicle and track properties. Vehicle modes of vibration are: longitudinal – contributing to general ride; vertical/bounce and pitch – contributing to vertical ride; lower sway; upper sway and yaw which contribute to lateral ride. The frequencies and how much different modes are excited depends on details of vehicle and suspension design.

Track quality also affects vehicle ride, and some knowledge of track quality is necessary in choosing the suspension options. Bridget outlined the EN12299 standard for assessing passenger comfort. This standard is based on significant practical testing of passenger reactions in a range of vehicles. Ideally then, a specifier could simply say ‘please achieve ride performance measured using EN12299 on track’.

Challenges

Bridget explained that no single body – specifier, supplier, operator, or infrastructure manager – has overall control. Other assessment methods also have challenges such as: (i) simulation (how to validate the model?); (ii) test track testing (are the conditions representative?); (iii) testing on the actual route (are the conditions predicable and repeatable?); or (iv) comparison with existing trains (how does the supplier know that the existing train is representative?). This illustrates why it is difficult to write robust specifications and how suppliers can easily challenge them.

Phil Rogers from Atkins continued by describing 11 factors that affect a passenger’s ride, only three of which can be influenced by a dynamics engineer. Phil gave a brief masterclass on suspension design beyond the scope of this article, but key principles were that primary suspension should be stiffer than secondary suspension and there should be good isolation between body and bogie dynamics.

For a good ride, soft suspension is desired both vertically and laterally. This requires well controlled damping, progressive bump stops, and good vibration isolation which considers all transmission paths. But, Phil added, it is not that simple. Engineers generally have to balance their desire for softness against the need to manage gauge constraints by tightly controlling vehicle movements. Factors include roll stiffness (which affects primary suspension stiffness), lateral stiffness, lateral bump stops (which affect ride when curving), and anti-roll bars (which are limited by required twisted track performance). An example is the choice of inside or outside frame bogies.

To manage roll stiffness, an inside frame bogie might require much stiffer primary suspension than the equivalent outside frame bogie.

With so many parameters affecting ride, optimisation using simulation is a key ingredient. The simulation must use models of key components, take account of the effect of body flexibility, wheel/rail conditions, and include representations of track conditions that vehicles will face when operating, including jointed track. The design/simulation also needs to accommodate a wide wheel/rail effective conicity range to help maximise wheel life while avoiding body or bogie hunting. Even then, poor detail design can let down a theoretically good set-up. Phil cited examples. Are the body to bogie connections optimised? Is the bodyshell stiff enough? Is the required end stiffness achieved on dampers? Have all noise/vibration paths been considered – e.g., dampers, anti-roll bar links, traction links?

For the future, Phil said that designers might look at less conventional solutions such as progressive bump stops, switchable dampers, active lateral dampers, or inerters devices that exert force relative to the acceleration they experience.

Seats

Even if the ride quality is sorted, there’s still the seats to consider. Rail Engineer covered this in issue 176 (July 2019), reporting the results of RSSB research project T1140. Since then, the research has been turned into a guidance note (GMGN2696), which RSSB’s Barry Tan introduced. He also described the next stage of seat comfort research (T1314): Evaluating Dynamic Comfort Factors, which will use the University of Huddersfield’s THOMoS train motion simulator for validation.

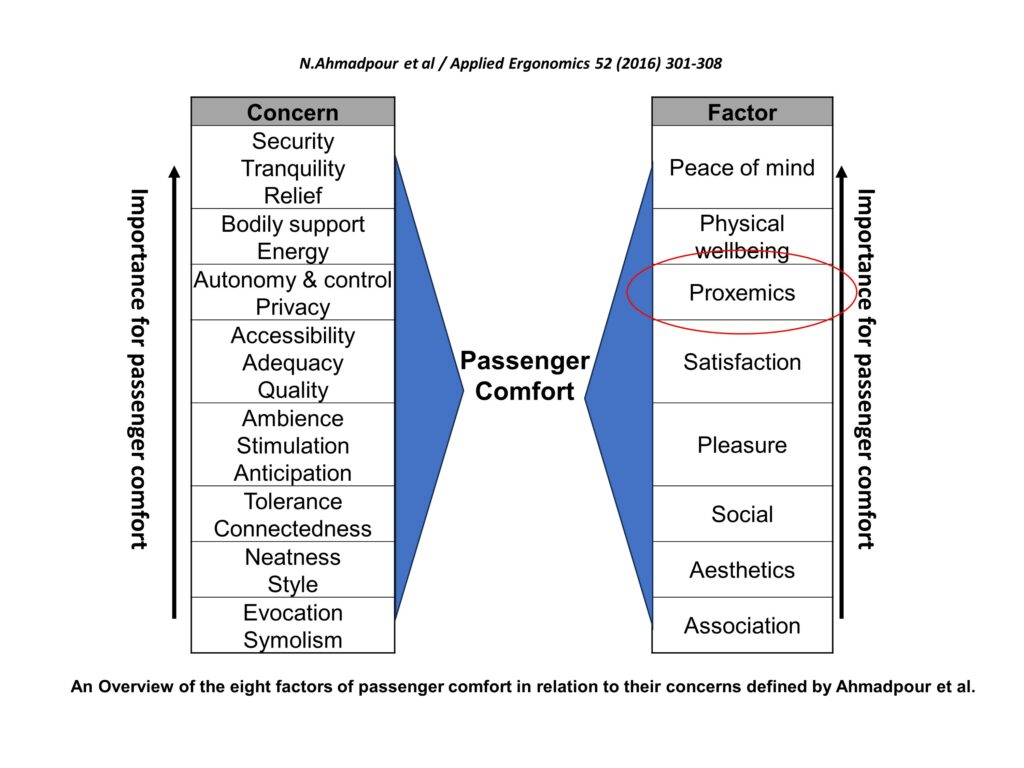

Barry talked more generally about comfort – a sense of wellbeing or the absence of discomfort. He illustrated the issue with various subjective factors explained by Ahmadpour et al, 2014. Other non-rolling stock comfort factors include stations/interchanges with clear signs and good waiting rooms, reliable frequent services with good connections and the feeling of discomfort whenever a rail passenger sees the dreaded words ‘Rail Replacement Bus Service’.

Martin Ward, head of fleet technical (deputy rolling stock director), at the West Coast Development Partnership talked about turning a seat concept into practice. In Martin’s opinion, rail seats serve different purposes, according to the type of rail service and possibly the length of the journey. Metros need seats to be functional, but comfort is probably less important than seating capacity. On longer distance regional and inter-city rail services, comfort becomes more important.

People

Seat design is also affected by what people do on trains. Journey purpose affects the way in which people will sit. Are they working or relaxing? Watching a video? Trying to sleep? Eating a snack? Passengers need to be able to move and adjust their position, but remain comfortable. A train seat must try to accommodate this wide range of requirements.

Martin has been involved in seat development for Avanti and Lumo, a process that started after the adverse media coverage of ironing board seats around 2017/2018. While noting Ian Wright’s comments about the comparatively low priority passengers place on seat comfort Martin said: “We do know it plays an important role in overall passenger satisfaction, particularly for longer journeys”. When planning the Lumo open access operation, First Group worked with a design agency called ‘forpeople’. Proposals for seat pitch and seat angle were developed together with options for seat layout, bay, unidirectional, staggered, etc. Passenger testing of seats was also carried out for the West Coast franchise bid where it was known that the Pendolino trains would need a mid-life refurbishment. Passenger feedback was, as might be expected, mixed.

While market research initially indicated that the current Pendolino seats and proposed new seats were similar, a more considered response led to a preference for a new, more reclined seat. For the majority, the more reclined seat offered more comfort, the ability to recline/relax, and greater support. And while the current seat’s upright position could be seen as offering a better environment when working, there were concerns about the seat’s configuration in providing comfort on longer journeys.

All this led to the use of a seat from Transcal for all seats on the Lumo Class 803 trains and in standard class on Avanti Pendolinos and classes 805/807. These seats and the extending seat-back tables have received a big thumbs up from passengers, said Martin. The new seats have thinner seat backs than those they have replaced but are still rated as comfortable, showing the importance of good design and passenger testing.

Advanced simulation

Julian Stow from the University of Huddersfield Institute of Railway Research introduced its Rail Vehicle Ride Simulator, THOMoS (Train Hi fidelity On-board Motion Simulator) – see also Rail Engineer issue 195. As already discussed, evaluating ride comfort is difficult. Passenger comfort is subjective, and people will experience the same conditions differently, while standards try to fit analytical measures to data from human participants in ride tests, but the results can be difficult to interpret. On track passenger comfort tests are very expensive. They need a large cohort to get useful results and changing track or vehicle conditions (e.g., track quality, suspension settings, seats) is not easy. Julian wondered whether these factors taken together might have reduced the focus on passenger comfort.

But, he said, simulation and motion reproduction technology has improved. For example, a six degree of freedom motion simulator can provide a highly realistic, repeatable experience at a comparatively modest price. This led to the development of a laboratory rail vehicle motion simulator, THOMoS or, as Julian put it ‘any vehicle, on any journey, in any conditions’.

THOMoS allows full motion replay of vehicle dynamic simulations. Any vehicle (from trams to high-speed rail) and any route can be simulated using a high-performance motion system. Up to four seated/standing passengers can be accommodated and, to make sure the simulation is realistic, there is 160km of urban/rural scenery, viewed through the ‘windows’ with accurate visual cueing such as simulated tilt. The interior can be configured with table or airline style seats, day or night can be shown, and the audio system provides for diesel or electric traction and rail joints, curve squeal, braking noise, and more. Full audio-visual recordings are available too.

Julian outlined the possible applications of THOMoS which include: a live demonstration of vehicle dynamics simulation results; ride comfort assessment for seated and standing passengers; immediate assessment of comfort and human response to varying curve transition design and switch and crossing alignment (including high speed); assessment of vehicle interior comfort (seat design, layout, temperature etc.); investigating trade-offs between suspension design and track geometric quality; testing interior fixtures, fittings, and equipment; and examining passenger response to unusual situations.

As always, even simulators need to be optimised and Julian described the lessons learned:

- Careful attention was required to tune filters in the system.

- Realism was enhanced considerably by attention to detail, e.g., floor rumble, sound level, and braking/acceleration.

- Simulation output must be flawless requiring careful model validation and high quality track data.

- Test design requires careful selection of ‘passenger’ cohort selection (size/mix), how data is gathered and the length of test.

The Track-Train System

The track is, of course, a key part of delivering good ride comfort. If the track is smooth and conforms with modern standards, the suspension designer’s task might be eased a little, and, while this is the track engineer’s objective, John Edgley, Network Rail’s Chief Track and S&C Engineer explained some of the challenges.

Track is a system which includes the land (formation) on which the ballast is laid, sleepers, rails, and fastenings. There can be defects in each of these, both individually and in combination, as John illustrated. The track is not rigid and the way it reacts to traffic running over it varies, often depending on the nature of the formation; e.g., rigid obstacles in otherwise flexible formation. Individual components such as sleepers and fastenings fail, and rails are often subject to damage arising from train movements – a location issue or a train fault. Switches and crossings present their own challenges. Switches can rarely be preceded by transition curves and there can be no cant on points. Hence there is usually a small jerk over the turn out. The challenge is to minimise such jerks to avoid, for example, standing passengers caught off balance.

John also highlighted the impact of the weather. During a long hot period, there can be problems with rail buckles and also reductions in soil moisture leading to track geometry changes. However, new technology and better methods of analysing vast data sets from passenger trains equipped with track/infrastructure monitoring equipment might help target faults more efficiently. Summing up, he said the quality of track has improved in the 20 years since Network Rail was created, and there are areas of excellence. He said that the order of priority was safety, reliability and then ride, and that weather resilience and climate change have provided extra challenges.

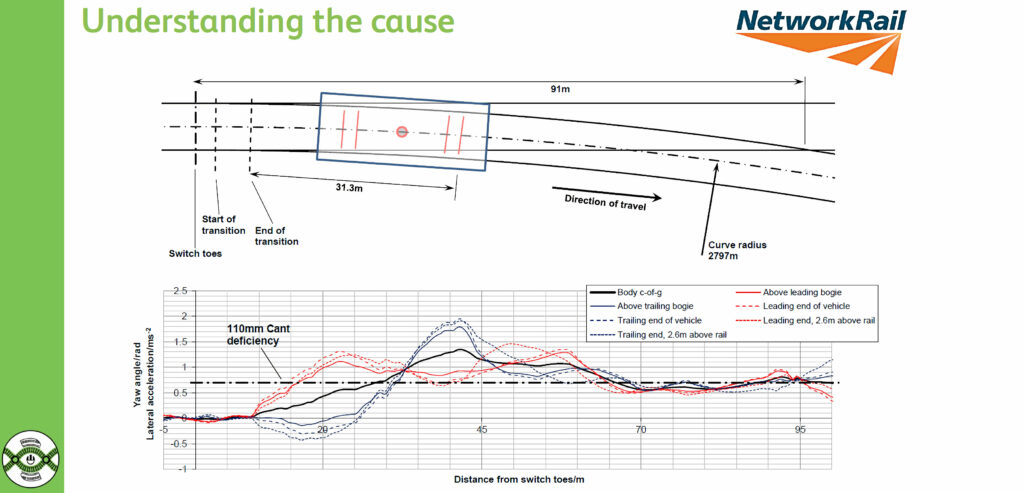

Dr Mark Burstow, Network Rail’s principal vehicle track dynamics engineer, presented case studies explaining poor passenger comfort arising from a combination of train and track features. An example related to a turnout in the Norton Bridge area, designed for 100mph running, where the train operator was reporting poor ride through the points on the rear vehicle of the train.

Observations showed that the poor ride occurred beyond the switch toes and that the layout had been correctly installed and was within acceptable tolerances. “Is it a problem with the train or the track and what can we do about it?” mused Mark. He presented results that the simulated and measured accelerations were within acceptable limits but when assessed against the ride comfort measure for discrete events in EN 12399 it confirmed the observations of people riding in the vehicles concerned. While not ideal, a 10mph speed reduction to 90mph was enough to bring the ride within tolerable limits.

Real-time monitoring

Mani Entezami, senior research fellow at the University of Birmingham, discussed an advanced real-time monitoring system for track geometry and ride comfort using in-service trains. Amongst his tests, sensors had been fitted to the axle boxes, above the primary suspension and above the secondary suspension, at each end of a Class 158 and Class 170 unit. Each sensor was intended to identify particular issues. Accelerations, speed, location and direction of travel were recorded. The recordings were processed with UoB-developed data processing algorithms to demonstrate the ride comfort standard information and track geometry parameters that are similar to Network Rail’s measurement fleet. Data consistency was vital, and Mani showed three examples from the bogie-mounted sensors where remarkably consistent data were collected. Track engineers often find it difficult to identify rough ride locations identified by drivers and Mani highlighted once such case where a driver identified a ‘lurch’ between mile posts 52 ¼ and 52 ½. No fault was found, Mani said, but the data showed that the fault was actually at 52.6 miles.

On High Speed 1, similar equipment but with extra axlebox sensors had been fitted to each end car of a 16-car Class 374 train, and considerable differences in ride comfort results were observed between leading or trailing sensors on the same track.

Mani explained that the trainborne measurement enabled the effectiveness of track interventions to be assessed quickly, possibly allowing earlier removal of speed restrictions. He also found that in one location the track renewal delivered the desired result, but ride deteriorated over the transition between existing and renewed track. In summary, monitoring track from service trains offers:

- More frequent and relevant data from the fleet using the line routinely.

- More accurate modelling of track degradation.

- Immediate assessment of track maintenance outcomes.

- Removal of speed restrictions.

- Detection of the cause of rough rides, e.g., hunting, bumps etc.

- Identification of vehicle-performance issues with rough rides.

- Ride quality reports.

- Monitoring of wheel impacts and wear.

- Updates on suspension performance.

Conclusion

Attendees left the seminar understanding that passenger comfort is a complex issue and ride comfort is a complicated system issue that no one party can control. That said, it was clear that seat comfort is important and simply putting in a large number of seats does not necessarily address the needs of all passengers. There are engineering standards that help when specifying trains and track, but even then, as Dr Burstow described, ‘compliant’ trains and track can sometimes exhibit undesirable properties.

Fitting sensors to trains to measure ride and track quality (together with bearing and wheel wear, if enough of them are fitted) has the potential to transform our understanding of how trains ride on each section of track, which might vary from modelled results. After all, even Formula 1 teams have to tune the suspension of their cars when they run on each circuit, despite having access to simulation tools that rail engineers would envy.