The three words that the public most associate with hydrogen are ‘Hindenburg’, ‘Explosions’ and ‘Hiroshima’. I learnt this on the stand of the Department for Business, Energy, and Industrial Strategy (BEIS) at Climate Action’s Hydrogen Transition Summit which took place in COP26’s green zone. BEIS is assessing how people think about hydrogen which is likely to be heating their homes in the not-too-distant future. It seems it might be a hard sell, yet the idea was mooted a long time ago.

In 1874, Jules Verne wrote of a world where “water will one day be employed as fuel, that hydrogen and oxygen which constitute it will furnish an inexhaustible source of heat and light, of an intensity of which coal is not capable”. At COP26, much was said about the need for a substantial hydrogen economy if net-zero carbon emission is to be achieved. As this strengthens the case for hydrogen trains, the opportunity to learn from world experts at COP26 was too good to miss.

Wind is the new oil

In his welcome address, Michael Matheson, the Scottish Government’s Cabinet Secretary of Net Zero – Energy and Transport, stressed that hydrogen is a crucial element of the transition to a low energy future. He advised that his government’s ambition was for Scotland to have a strong hydrogen economy and that it had published its hydrogen action plan which includes an installed hydrogen production capacity of 5GW by 2030 and 25GW by 2045. It also commits £100 million towards the development of Scotland’s hydrogen economy over the next five years.

He felt that Scotland was well suited to produce the lowest cost hydrogen in Europe with an abundance of fresh water and some of the world’s best offshore wind resources, with commitment to install an additional 8-12GW by 2030. Its redundant oil infrastructure offers cost-effective carbon storage to support the production of low-cost, net-zero carbon hydrogen at an industrial scale. Moreover, well-established sectors such as oil and petrochemicals have the skills to diversify into a hydrogen economy.

Hence, it is expected that Scotland will eventually export much of its hydrogen. To this end, part of the hydrogen action plan is the development of the required transportation and distribution infrastructure. A strong hydrogen supply chain is also required, the development of which is supported by a £100 million renewable hydrogen development fund. In addition, funding is being made available to support hydrogen hubs that combine production, storage and distribution with multiple end use applications. The Aberdeen hydrogen hub is to receive £15 million from the hydrogen development fund.

In closing, Michael emphasised that hydrogen is a key tool in the climate change toolbox which represents a huge opportunity that everyone should seize with both hands.

Grey, green, blue and turquoise

Worldwide production of hydrogen is 80 million tonnes per annum. Although it is a hazardous gas, its properties are well known and there are proven technologies to store and transport it. However, currently almost all production is grey hydrogen from reforming methane which produces emissions only slightly less than those of liquid fossil fuels.

If hydrogen is to help provide net-zero emissions, it needs to be either blue hydrogen (produced by reforming with carbon capture and storage) or green hydrogen (from electrolysis powered by net zero electricity). However, hydrogen produced by electrolysis plants may be turquoise as it may not be possible to use 100% net-zero electricity all the time.

The market

Roman Kramarchuk of S&P Global Platts considered that, rather than colours, it is more meaningful to consider hydrogen’s carbon intensity. With hydrogen accounting for 5-10% of the world’s energy supply. Price Waterhouse Cooper estimate that, by 2050, the green hydrogen export market will be 200 million tonnes, worth $300 billion per annum. If this market is to function, guarantees of carbon intensity will be required as grey hydrogen will always be less expensive than that of green hydrogen.

Seifi Ghasemi, Chief Executive of Air Products, noted that the reality is that green hydrogen is expensive compared with fossil fuels, but we need to use it if we are to decarbonise. Like many speakers he felt a global carbon tax was necessary to provide the right incentives. He feels the role of government is to promote the use of green hydrogen. Once there is a demand, he has no doubt that business could scale up production to meet it.

To make use of existing assets, he feels the first step had to be blue hydrogen with carbon capture. He advised that Air Products had committed £15 billion dollars to produce hydrogen, including a large blue hydrogen facility in Canada and on the US gulf coast, together with a huge plant to produce green hydrogen in Saudi Arabia.

Dr Emmanouil Kakaras of Mitsubishi Heavy industries said he has no doubt that the technology to produce hydrogen at scale is available now. He also feels that there is no time to invent new technologies, though he considered that a gamechanger for blue hydrogen would be producing carbon black as a by-product, as another form of carbon capture. Rod Christie of Baker Hughes agrees and is convinced that economics is the issue and tax incentives are required, though he feels that government promotion of hydrogen clusters is useful in getting a lot of players “on thesame page.”

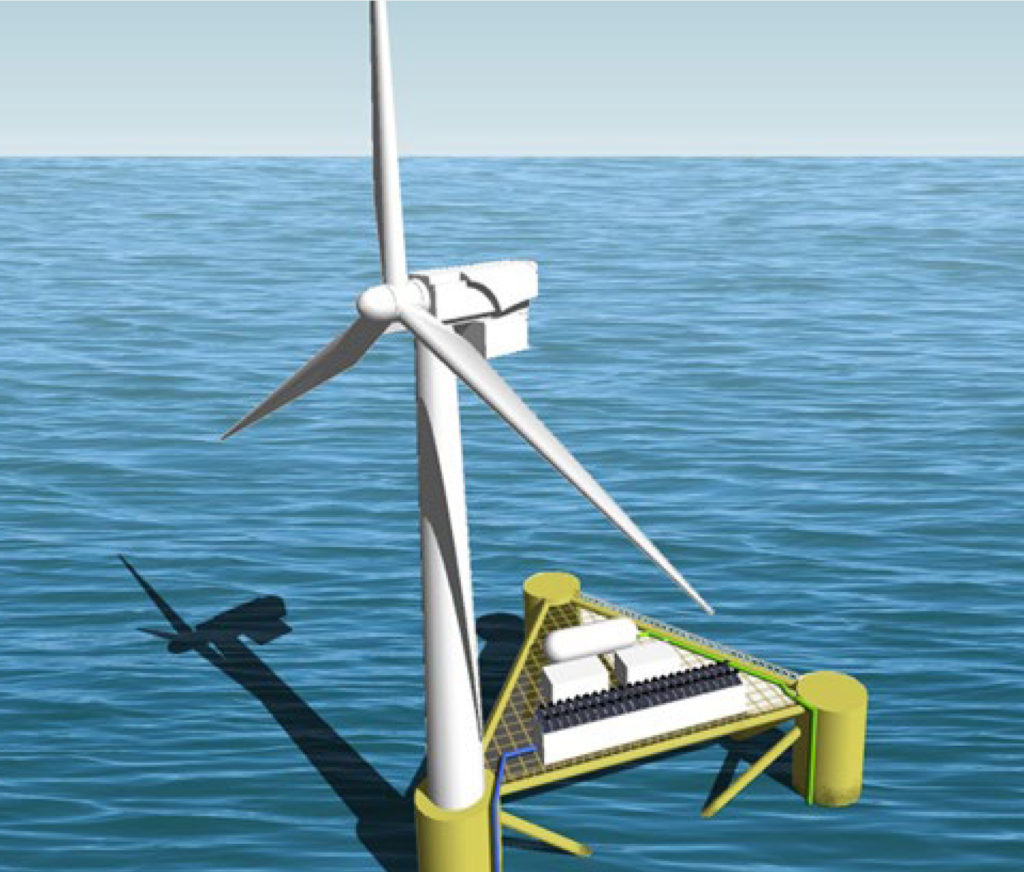

David Caine of Environmental Resources Management (ERM) described the Dolphyn project, which combines an offshore floating wind turbine with green hydrogen production and requires a desalination plant. He considered that the offshore floating wind sector had the most reliable wind and that hydrogen is the most efficient way of transmitting energy back to shore from such deep-water facilities. He expects that such plants will be able to produce hydrogen at less than $2 per kilogramme and advised that a 10MW commercial scale demonstrator close to Aberdeen would be operational by 2024. It was expected that a 300MW plant will be operational by 2028.

Using hydrogen

All speakers agreed that hydrogen is a versatile fuel that is essential for a low carbon economy and that it is the only way to eliminate greenhouse gas (GHG) emissions from things that cannot be directly electrified such as ships, steel production, and heavy mobility. Filippo Gaddo of Arup considered that in a net-zero world, hydrogen would be 5-15% of the world’s energy supply.

Although, in general, the most efficient use of hydrogen is by fuel cells, it can also be burnt directly. Raphael Schoentgen of Hydrogen Advisors stated that using hydrogen in gas turbines was straightforward and Emmanouil Kakaras noted that the marine sector had successfully burnt ammonia, a compound of nitrogen and hydrogen, in existing diesel engines. David Bryson of Uniper stressed that the transition to hydrogen fuel had to use existing assets in this way and avoid assets being “stranded”. Hydrogen will also have an important role balancing a future energy network largely powered by variable renewables.

Dr Fiona Simon of Australia’s Hydrogen Council considered that a major hydrogen pipeline network would be needed as this is the most efficient way to transport hydrogen above a certain volume. She also feels that there was a need for international standards to support worldwide carbon trading.

Shiva Dustdar of the European Investment Bank advised that a €1 trillion investment for climate action needed to be mobilised by 2030 to support the Paris agreement. In 2020, her bank had financed €12 billion of climate investments of which hydrogen was a “modest” €2 billion. She acknowledged that more investment in hydrogen was needed but feels there is a lot of political momentum for this with many EU member states developing hydrogen strategies.

The requirements for greater use of hydrogen were nicely summed up by Rosalinde van der Vlies, Director of Clean Planet at the European Commission. She considered that three things were needed: “political vision; a supportive regulatory framework; and an investment agenda.”

Hydrogen in the home

Although buildings account for about a third of UK GHG emissions, there is currently no definitive strategy to eliminate emissions from domestic heating. Various options include heat pumps, district heating schemes and the use of hydrogen which could make use of the local gas pipeline network. However, the feasibility of hydrogen for heating buildings has yet to be proven.

To consider this, the Department for Business, Energy, and Industrial Strategy (BEIS) set up the Hy4heat initiative in 2017 to establish whether it is technically possible, safe and convenient to replace natural gas with hydrogen in residential and commercial buildings. BEIS’s Deputy Director of Energy and Innovation, Dr Mark Taylor, explained this initiative.

Mark noted that the 2019 change in the Climate Change Act target, from an 80% reduction of the 1990 baseline to net-zero emissions, was extremely challenging. He advised that his department estimates that green hydrogen could save 9% of GHG emissions as well as supporting up to 9,000 jobs by 2030 and potentially unlocking 100,000 jobs by 2050.

The Hy4heat initiative is a four-year £25 million programme, that BEIS launched in 2017, to assess the feasibility of using hydrogen in homes, commercial premises, and industrial heating. To date it has shown that injection of colourant is unlikely to be required and that hydrogen can use the same odorant as natural gas. It has also produced guidance notes on safety certification for hydrogen appliances and a competency framework for gas engineers. A safety assessment, that has been independently reviewed by the Health and Safety Executive, has also concluded that hydrogen can be made as safe as natural gas when used for heating and cooking.

Hydrogen neighbourhood

Two months ago, a Pilkington’s glass furnace was fuelled by hydrogen. To date over 150 hydrogen domestic appliances have been developed and there are now two demonstration hydrogen houses in Northumberland. BEIS has launched various competitions to promote the use of hydrogen which include a £10 million green distilleries competition.

Mark advises that the next step is the world’s first hydrogen neighbourhood. In 2023 up to 300 homes in Levenmouth, Fife will be able to opt-in to have their homes supplied with hydrogen from a purpose-built local grid. Those participating will receive free hydrogen appliances and pay the same for hydrogen as they would for natural gas. This pilot project is to be supplied from a 5MW electrolyser that can supply two tonnes of hydrogen per day. A hydrogen village using the existing gas grid is planned for 2025 and a hydrogen town for 2030.

He considered that the Levenmouth pilot scheme was pivotal as the next steps were dependant on its success and will inform strategic decisions in 2026 on the role of hydrogen in heat decarbonisation.

Baxi’s Managing Director, Karen Boswell (formerly of Hitachi Rail), noted that gas boilers had been in use since the 1960s and are the workhorse of domestic heating. The UK Government’s plan to phase out the installation on new boilers beyond 2035 presents a significant problem as heat pumps are not suitable for all premises. Baxi has developed various hydrogen appliances and, in 2019, showcased the world’s first hydrogen condensing domestic boiler. By 2024 the company intends to produce hydrogen ready gas boilers.

Karen feels that hydrogen will have a strong role in decarbonising buildings and recognised that heat pumps will work in some buildings, heat networks in others. Baxi’s role is to listen to its customers and help them find the right solution.

Karen referred to the UK Government’s hydrogen strategy and felt that its target of a 5GW green hydrogen annual production capacity by 2030 was “underwhelming”. She felt that the infrastructure “will need to move more quickly to get this market growing” and that “if production is ramped up, there are no limits on the number of homes that could be converted to use hydrogen.”

Jules Verne was right

All speakers at the summit were clear that hydrogen presents a huge opportunity for achieving global decarbonisation goals and supporting new economies around the world. Averting a climate disaster requires the world to be weaned off fossil fuels which, in part, requires the novel use of hydrogen at scale for which technologies already exist. The summit’s firm consensus was that, if hydrogen is to be affordable and accessible for all, policy and finance have a key role.

Two key themes that emerged during the day were the importance of creating a strong end-use market and the synergy between hydrogen and renewable power generation.

For someone with an interest in hydrogen trains, it was a fascinating day. Yet, while the summit addressed many big picture issues, it did not consider the role of hydrogen for transportation. The only end use application considered in detail was hydrogen’s use for heating. Dr Taylor of BEIS demonstrated that the UK Government has an effective programme in this respect, which included some world firsts. Over the past four years BEIS has invested £78 million on green hydrogen supply, Hy4heat, and industrial fuel switching.

While there was hardly any talk of hydrogen trains, this was no bad thing. It underlined the point that hydrogen trains will eventually be a small part of a much larger hydrogen economy. This must eventually drive down the price of hydrogen and support hydrogen train operation to strengthen the case for their use.

It is certainly true that, per coach, hydrogen trains have a greater power output than the steam trains of 1874, when Jules Verne predicted that hydrogen from water will one day provide a source of power that surpasses that of coal. As far as trains are concerned, it seems that his prediction has now come true.