Rail Engineer has been following the activities of the rail industry’s Adhesion Research Group for some time and has reported, amongst other things, on Double Variable Rate Sanders (DVRS) and rail head cleaning, as well as modelling and simulation tools.

The latest event – the ADHERE 2021 webinar series – took place in March and April, and reported progress on these developments as they seek to bring the technologies to market and make the business case for their adoption. This article covers some of the event highlights, with more to follow in the next issue.

Double Variable Rate Sanders

Previous tests have demonstrated conclusively that DVRS delivers an effective braking performance even in appalling adhesion conditions; a little sand in the right places really does work wonders. In this session, the speakers explored the benefit to be gained by exploiting DVRS and the business case for retrofitting to existing trains.

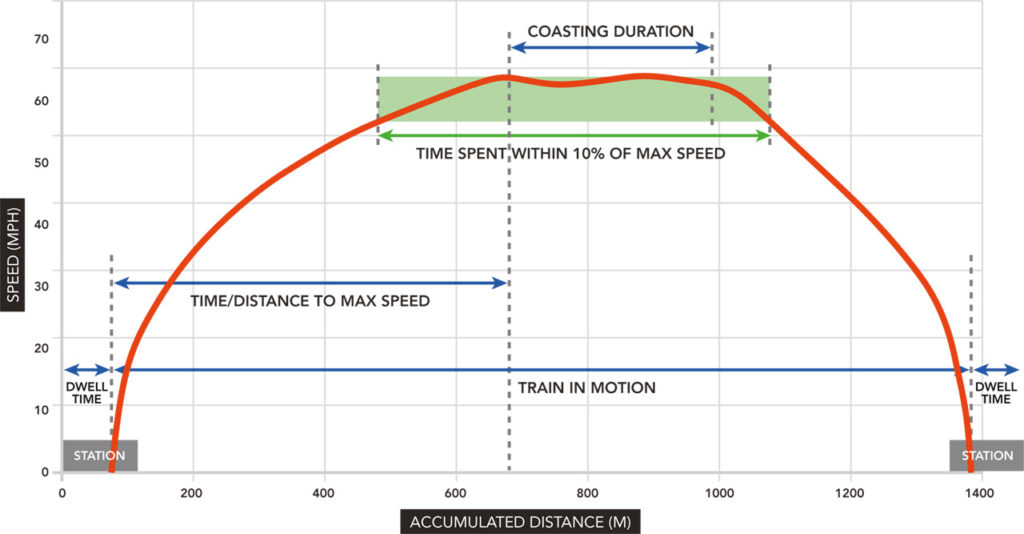

Peter Watson, Ricardo Rail, described the analysis of data from six specially equipped Class 323 units – two fitted with DVRS – deployed on the Birmingham Cross City route which is notorious for autumn leaf-fall performance issues. This line has 22 to 25 stops, depending on route, with a typical run time of 150s between stops for a typical distance of 2.3km. Each station-to-station run comprises four phases: dwell time, acceleration to maximum speed, coasting and brake to stop at the next station.

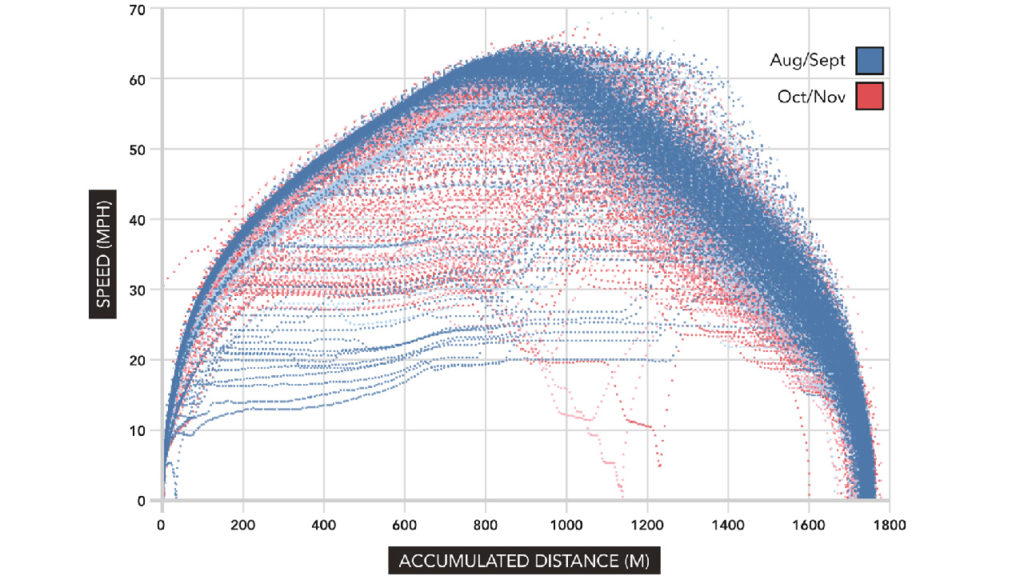

Peter said that the units were monitored during the period June to December 2019 to provide summer and autumn data, allowing detailed analysis of each of those four phases for every journey.

He highlighted a typical inter-station run to illustrate the principle and then showed superimposed speed distance curves for each inter-station run – both northbound and southbound – coloured blue for summer and red for autumn. These showed variable driving styles. In general, the red traces were lower and more variable than the blue traces indicating that autumn performance was generally slower than summer.

74,000 journeys were analysed, a total of over 0.5 billion records. There were delays in each of the four phases, with autumn running slower than summer by these average amounts – dwell time, circa 2.5 seconds; acceleration, about 1 second; cruising speed, about 1 second; braking, 4 seconds. It is worth noting that the Class 323 has 66% axles motored and other classes – with a lower percentage of axles motored – might suffer more problems with acceleration in the autumn.

Summarising the data in three figures, Peter said that dwell time and run time were on average 2.5 seconds and 6 seconds respectively slower in the autumn than in summer, which totalled circa 87 seconds delay over a whole journey. Small autumn delays accumulated along the line to become significant delays which were, on average, not recovered.

Peter concluded that DVRS would provide confidence in braking and, with suitable changes to driving policy, performance in the autumn could be little different to that in the summer.

DVRS Business Case

This quantified impact on performance is vital in developing the business case for retrofitting DVRS which was presented by Iain Flynn, Rail Delivery Group, using this and other industry data.

Iain said that there has been a fairly consistent drop in the Public Performance Measure (PPM) of just over 5% during each of the last ten autumns. This is because trains cannot consistently deliver a brake rate of 0.6m/s2 – the brake rate assumed in the timetable. Professional driving policies can also lead to train braking at a lower rate than the available adhesion would permit. This costs the industry approximately £100 million per annum, with the overall disbenefit to society estimated at circa £300 million. The business case proposition was “DVRS would guarantee 0.6m/s2 braking year-round and, with reform of driving practices, the loss would be largely eliminated.”

Iain said that a bid to Network Rail’s Performance Innovation Fund (PIF) for retrofitting DVRS to the 43-unit Class 323 fleet had been successful. He had used a similar evaluation process for the rest of the GB passenger fleet delivering a CAPEX estimate of approximately £330 million, circa £2 million OPEX costs and some £66 million of benefits per year, indicating a payback period of 8-9 years.

He warned that there is an issue with the rollout of ETCS and the way it has quite crude allowances for low adhesion. This may be a significant problem. There is a parameter called Kwet which is a measure of a train’s low adhesion performance; the rules dictate that this value is established with the sanders disabled. The emergency braking curve for nearly all passenger trains may therefore be pessimistic at all times, with or without DVRS. This will affect headway performance more than run times. Perhaps it is time for sanders to be an essential part of the safety-critical braking system.

Ending on a positive note, Iain said that DVRS is the single biggest performance initiative available to GB Rail using simple and proved technology, giving 0.6m/s2 braking on poor adhesion days. This, together with targeted, vegetation management and more attention to detail of water jetting, could provide a near complete autumn solution.

Braking developments

Paul Allen, Institute of Rail Research at the University of Huddersfield (IRR), and Phil Martin, Transport Research Laboratory (TRL), talked about ‘Predictable and Optimised Braking: An Intelligent Blended Braking (iBB) Approach’ funded by RSSB and led by Alstom, with support from Knorr Bremse, Northern Trains and Wabtec-Faveley.

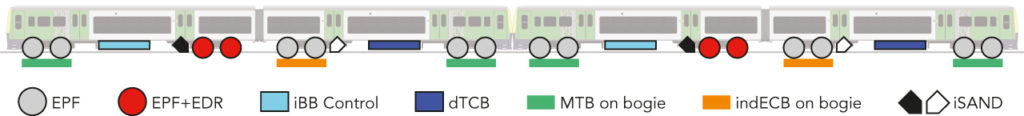

iBB is essentially the intelligent blending of conventional and adhesion-independent/adhesion-raising brake system technologies, the simulated systems consisting of Electro-Pneumatic Friction brake (EPF), Electro-Dynamic Regenerative brake (EDR), Eddy Current Brake (ECB), Magnetic Track Brake (MTB), intelligent sanders and adaptive Wheel-Slide Protection (aWSP) which adapts its control algorithm to the level of adhesion.

‘Intelligent braking’ means that the applied brake rate can be varied along the train to make the best of or even improve the adhesion levels whilst delivering the brake rate demanded by the driver, controlled by a dynamic Train Brake Controller (dTBC) – in essence, the high-level controller of aWSP. This compares with the conventional systems where the same brake rate is applied along the train unless the WSP intervenes to reduce the brake application on one or more wheelsets.

IRR’s LABRADOR modelling tool was used to assess the impact of these brake systems individually and in combination. The aim was to deliver 0.6m/s2 braking under very low adhesion conditions (adhesion coefficient of 0.02).

The researchers were keen to assess the benefits of braking solutions that are independent or semi-independent of adhesion. ECBs work something like a linear induction motor in dynamic braking mode and need no adhesion to operate, but they are ineffective at low speeds. Another technology is MTBs where bogie-mounted electro-magnets grip the rail head. Although MTBs still rely on friction, they tend to scrape off any contaminants on the railhead, making them very effective brakes.

Simulation work

The train model was based on the dynamics of the Class 458 EMU and the characteristics of the various braking systems were provided by the suppliers, sometimes based on the expected performance of products not yet on the market. Theoretical four-car and two-car configurations were tested using three adhesion conditions for various levels of performance: Step 2 and 3 brake rates, variable starting speeds, degraded mode operating and for the individual performance of the various sub-systems.

Work was carried out on Wabtec Faiveley’s four-axle rolling rig in Italy to study the adhesion interactions between axles specifically to establish how various aWSP algorithms enabled increase in adhesion from one axle to the next.

The simulation work demonstrated that the target of delivering a 0.6m/s2 brake rate in very low adhesion conditions is indeed possible and can be achieved for a four-car unit without the need for adhesion-independent braking systems. Paul asserted that this is potentially of great significance to the industry as the solution relies solely on an upgrade to the sanders, WSP and brake system control strategy, and therefore offers a practical solution as an immediate response to the adhesion problem.

Paul said that delivering a similar outcome for a two-car unit was much more challenging. With only eight axles, Paul said it was unlikely that the 0.6m/s2 brake rate target in very low adhesion conditions could be achieved without adding additional systems such as the ECB.

Based on TRL’s work using their TRIO rail operations performance modelling tool, the best business case for retrofit was for aWSP and intelligent sanding, but a strong business case could be generated for adhesion-independent brakes (ECB or MTB) if they were considered at the new build stage. Paul also outlined plans for further research including service trials with TOC support, refinements to the business case, understanding the impact of MTBs on existing infrastructure and understanding how well MTBs condition the railhead.

Thanks to RSSB and the speakers for their help in the preparation of this article.

The second part of our review of ADHERE’s 2021 webinar series will appear in the July/August issue of Rail Engineer.

Rail Engineer thanks, I notice you don’t like truth bombs based on ordinary level logic.