Our companion article in this issue about the new Docklands Light Railway trains acknowledges the significant role of KeolisAmey Docklands (KAD) on the project and in delivering the DLR’s day-to-day service as Transport for London’s (TfL) Operations and Maintenance partner for Docklands Light Railway Limited (DLR), part of TfL.

TfL / DLR owns the assets and, in safety certificate terms, is the infrastructure manager for the guideway infrastructure, whereas KAD maintains the trains and infrastructure and is the train and station operator and infrastructure manager for all stations. This article discusses how KAD works collaboratively with DLR to improve the performance of the existing trains, whilst ensuring safety and maximising efficiencies on the trains that are soon to be scrapped (B90/B92/B2K – hereafter B92) and also preparing for the new trains. All this was discussed with Tony Kempster, KAD’s rolling stock head of technical services in early October 2023.

Avoiding expensive interventions

From experience, new trains rarely arrive at a convenient time to dovetail with an existing fleet’s orderly maintenance plan. Plans have to be adapted with the aim that old trains are withdrawn just before the wheels are worn down to the scrapping limits and/or just before an overhaul is due.

KAD has developed a mileage control database system to help it manage all this. In brief, the trains report their station stops via the SelTrac CBTC system. As the distance between two stations never varies, this is converted into mileage. This new process was developed to enable more accurate measurements, reduce the requirement to physically access the vehicles, mitigate any inaccuracies and enable prediction of all the vehicle mileages for their remaining life.

KAD also knows the trains that are running with wheel tyres which need to be scrapped when worn beyond limits, at what mileage that is likely to occur, and when the next heavy maintenance is due. This information is linked to the mileage control database. Depot planners know the mileage of each train duty which allows planners to organise formations (two or three cars – a car is an articulated unit with two bodies and three bogies) and duties to give prominence to trains/formations that have plenty of ‘mileage life’ left before needing expensive intervention.

“This requires careful planning using the mileage control database,” Tony reported, “and sometimes, stopping vehicles for a while, although this does put extra strain on availability.” He added that most Maintenance Tasks are now carried out on a condition-based regime.

Implementing condition-based maintenance was a significant change which included assessing the assets’ baseline condition, changing all maintenance task instructions (to include pass/fail criteria), transition exams, and, of course, safety assurance.

But there is still a complex scrapping plan which, as well as taking account of the heavy maintenance needs, includes managing small wheels, bogie frame cracks (see Case Study Bogie Frames), auto coupler reliability restrictions, and some units with general reliability issues which Tony described as lemons.

An example of a condition-based maintenance activity introduced recently is extending the overhaul life of B92 traction motors; DC motors mounted longitudinally in motor bogies driving both axles. To justify postponing motor overhaul on trains soon to be scrapped, Tony identified that the biggest risk is failure of motor bearing. These carry the load of a heavy armature as the only suspension the motor sees is its resilient mounts on the bogies and the resilient wheels.

To manage this risk, KAD has adopted vibration monitoring of the bearings using the novel approach of rotating the wheels on the underfloor wheel lathe and measuring acoustic vibration in the bearings. For these cars, with just two traction motors/motor bogies, this is a fairly straightforward process.

Tony expanded on general reliability issues. B92 trains are between 23 and 33 years old. They use DC chopper control and other electronics which are life expired or obsolete. The electronic modules are connected to the train wiring with connectors that have suffered general wear and tear. This means that maintainers are often faced with difficult failures that could be a defect with an electronic module, a connector, or with the wiring. Given the life of asset, some of these problems are intermittent and can sometimes lead to challenging repairs or repeat defects with the train failing again.

B2007 trains

As the B2007 trains will remain in service for some time – they are about 15 years old – Tony reported that a lot of new, exciting projects are coming up mainly focused on maintaining and improving the fleet’s performance. These include replacement of obsolete systems, software updates, and installation of new systems. Tony illustrated one example – the Smart Oil Plug®. Unlike B92, B2007 cars have two motors per bogie (four per car) mounted parallel to the axles and driving the wheels through double reduction gearboxes. The Smart Oil Plug, powered by Transmission Dynamics, replaces the conventional oil filler, or drain plugs, designed and certified for axle-mounted operation to monitor temperature, vibration, and ferromagnetic oil debris – an indication of gear or bearing damage.

This wireless, sensor-based solution, developed by industrial data experts Transmission Dynamics and brought to the market by distribution partner ZF Aftermarket, enables real-time monitoring and analysis of gearbox health and behaviour in railway vehicles. The sensor can detect gearbox vibrations, providing insights into gearbox quality, wheel slide, track quality, impending bearing failure, and suspension defects. The plug, equipped with an onboard battery, transmits data to the control unit via Bluetooth and has a three-year battery life.

The control unit sends live data to a web portal through GSM, allowing ZF Aftermarket to provide KAD with real-time access to all data and alerts regarding adverse conditions. Additionally, the system offers longer-term condition monitoring recommendations to assist in maintenance planning.Currently, said Tony, the system is being evaluated to build up a picture of what the system is reporting and the results/alerts are being calibrated/correlated. ZF Aftermarket and Transmission Dynamics will be working with KAD to develop artificial intelligence to filter data and identify negative trends.

Integrating the new trains: Tony returned to the subject of new trains. He praised the team effort involving KAD Stores, Production, and Engineering Teams working well with the DLR Rolling Stock Replacement Project (RSRP) team.

Materials

It’s not just the new trains that will squeeze available space until the old ones are scrapped. The same is true of the stores. Additional storage is being created both off-site and on by obtaining 16 shipping containers. Tony added that slow moving B92 stock has already been moved into four containers which have been relocated to the new build area, freeing up depot space for building works/expansion. KAD is also in the process of clearing the materials located in the wheel lathe to allow work to begin expanding this location.

KAD is working with RSRP to develop and integrate new agreed processes to manage and, where necessary, segregate maintenance spares (exam kits), from warranty spares (owned by the supplier), customer owned materials (spares held in reserve but only obtainable with the main build), and new special tooling.

KAD has identified what parts can be salvaged from early scrapped B92s for possible use on trains to be scrapped later, i.e., items where the float is low or where they may avoid re-ordering. It has also identified 31 parts in common with B2007 parts (but inevitably not the same part number) and is working with London Underground to see if any components could be used across the tube fleet. The stores team is continually reviewing and monitoring stock levels to realise any efficiencies.

Staff

A number of new positions have been created to support RSRP such as project managers, commissioning technicians, material controllers, engineers, technical authors, and planners.

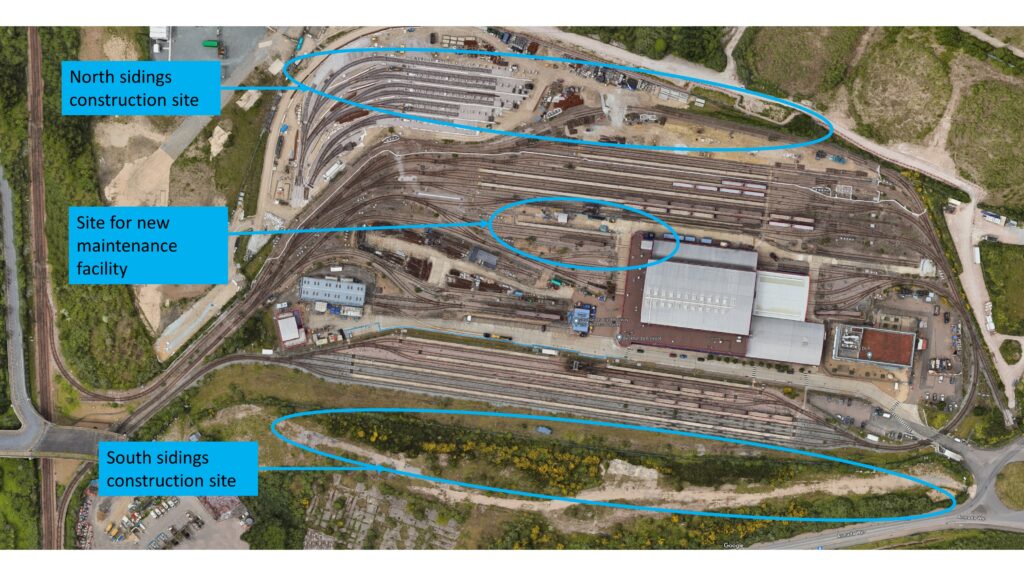

Tony talked about the importance of integrating the depot works with the introduction programme. The creation of more sidings on the north and south sides of the Beckton site gives a false sense of security as the construction sites are currently entirely separate from the depot. But when they start work on the maintenance shed, which will be in the middle of the depot, KAD Management will have to ensure everyone’s safety (KAD, TfL, DLR, CAF and various construction contractors and sub-contractors), whilst co-ordinating activities so that maintenance can continue to be carried out and a full service provided.

Tony illustrated this with preparations for wheel lathe works. Currently, around 28 metres is required either side of the wheel lathe to accommodate a car. But the new trains will need three times the amount of space each side and, Tony said, they are working with DLR to acquire a double headed wheel lathe to speed up reprofiling on a five-vehicle unit. Tony reported that a series of three-week part shutdowns is planned but this will need careful management as the wheel lathe road is not just used for tyre turning, but also for vibration analysis and graffiti removal.

New concession

The final part of the jigsaw is the retendering by TfL of the concession. The planned date for the new concession to start is in April 2025, before the depot upgrade, introduction of new trains, and scrappage of old trains has been completed – not the steady state usually sought for such changes. Tony stated that it’s a very exciting project at KAD, with the B92 cascade, B2007 reliability projects, new fleet introduction, and re-franchise. He reported that KAD is working closely and collaboratively with DLR to ensure that KAD’s work packages are delivered in the appropriate time.

It was good to see KAD’s plan for managing the introduction of the new trains while keeping the existing fleet running. No doubt there will bumps in the road during this process and Rail Engineer wishes success to everyone involved.

Case study: Bogie frames

In 2014, what proved to be fatigue cracking was observed in the B92 bogie frames. This led to a programme of NDT and repair which is still in place today. The root cause of the cracks was fatigue in both the parent metal and welds in high stress areas. The initial repair was by welding. However well they’re carried out, welded cracks in high stress areas are likely to fail again, but they buy time. By 2018, KAD was struggling with both vehicle availability, spiralling costs, and extended and forced delays to the bogie overhaul due to these cracks. More intrusive weld repairs followed but further cracks were found.

Something had to be done and DLR / KAD engineers started work to ‘reverse engineer’ brand new bogie frames with an independent subject matter expert to provide options for an internal strategy paper and a technical specification for the project.

The original design, detailed on a suite of drawings provided by OEM BN Bruges (part of Bombardier) was converted into a 3D model from which 2D drawings were produced. The specification proposed the following changes aimed at improving frame design and manufactured quality:

- Pre-production frames would be built and the experience would be used to simplify manufacture and allow the supplier to use current best practice.

- The supplier would propose improved weld details at the transom to side frame joint, which was the site of the most serious cracks, and that several unnecessary pipe clips would be omitted.

- The supplier would be invited to propose any other detail improvements that it would like to implement, provided that a justification can be offered for each one.

- The bogie frames would be fabricated in accordance with the requirements of the railway vehicle welding standard BS EN ISO 15085, instead of standards applicable to general fabrication welding used previously. Railway vehicle welding standards were developed in the period 2005 to 2007 to improve the quality and consistency of safety critical components such as bogie frames.

As owners of the vehicles, DLR initiated this work as a project at the end of 2018 and it was agreed that it would be managed by KAD. Several companies experienced in making bogie frames were interested but, after a procurement process involving rigorous technical evaluation, Hutchinson Engineering Ltd from Widnes was the preferred supplier. Hutchinson specialises in telecoms (antenna towers), renewable energy (wind turbine towers), and other major steelwork projects and was able to demonstrate state of the art machinery, technology and quality in design, fabrication, welding, and inspection. As Hutchinson was inexperienced with railway safety assurance, SNC-Lavalin (now AtkinsRéalis) was appointed to carry out independent assurance checks and surveillance visits when production started January 2020. The first batch of new frames (10 of 40) was delivered in March 2020 and the first nine frames (3 x vehicles) were subject to additional assurance measures/in service checks in place. A total of 130 frames has been ordered, 124 delivered, and, of these, 118 have been fitted. Just under 30% of the old frames remain crack free, and about 28% of the old frames have cracks being managed through the NDT programme.

Image credit: Malcolm Dobell / Tony Kempster