The Docklands Light Railway (DLR) has vastly increased in size since the original £77 million line opened in 1987 with 11, 28-metre-long trains. With extensions to Bank, Lewisham, Beckton, Woolwich, and Stratford International, and trains now three times as long, it is sometimes hard to understand why it is still called a light railway. But with the delivery of the first of the latest batch of trains from CAF, designated B23, the distinction between light rail and metro has become even less clear.

First, some terminology. Currently, a DLR ‘car’ is a two-body, three-bogie, articulated set approximately 28-metres-long. Today, trains rarely run as single cars; two-car and three-car trains are the norm. This terminology is having to be revised as the fixed formation B23 trains comprise five, two-bogie cars in a fixed formation that is 86.7 metres long, 2.65 metres wide, and has open gangways between cars. Each car is slightly longer than a London Underground S stock but noticeably narrower. This configuration provides some challenges, described later.

In 2019, TfL placed a contract with CAF for the supply of 43, five-car trains. Thirty-three are intended to replace all the life expired B90/B92/B2k (hereinafter B92) fleet with the additional 10 trains being used to support the projected passenger growth across the DLR network. In June 2023, TfL called off another 11 trains to further respond to growth in East London.

TfL is expanding Beckton depot to accommodate all 54 B23 trains, a net increase of 23 trains over current capacity. Moreover, maintaining an 86.7-metre train needs different facilities from those set up for 28-metre cars and visitors to the depot, who’ve arrived at from Gallions Reach station, walk past a significant building site where additional sidings are being built. There will also be an additional maintenance shed. But this article focuses on the layout and technology of the new trains based on a visit by Rail Engineer in September 2023.

Relationships

Project engineer Phil Shrapnell from TfL, together with Dave Collins and Andy Slade from Keolis Amey Docklands (KAD), hosted the visit and it was immediately obvious that they are an effective team.

Moreover, they paid tribute to the excellent working relationship with the CAF engineering team. Phil said that following contract placement there was a great deal of team building and co-operative liaison with CAF in Besain, Northern Spain, before Covid caused everyone to work remotely. The relationships built before lockdown helped effective remote working. Representatives of KAD’s Passenger Services Agents (PSA) also had input, in Spain, to the layout of operator touch points. But this cooperation went further. Phil explained that the specification was treated as a live document, with collaborative discussions between the London and Spanish teams to understand the real intent behind the requirements, allowing the evolution of the design to best meet the needs of the DLR.

Technology

Modern trains are complicated. Most of their systems are linked together by a computerised network, generally known as Train Control and Monitoring System (TCMS). On B23 it is linked to a shore system, a CAF system called LeadMind, which collects data for remote condition monitoring and can control some aspects of the train, an example being the bogie-mounted wheel flange lubricators. While all the trains have wheel flange lubricators, no one yet knows how much lubrication will be needed until all the trains are in service. But not to worry, Rail Engineer was told, the lubricators will be remote controlled from the control room.

Another new technology feature is a WiFi antenna in each car. This is for direct connection to a ‘phablet’ device using the Android operating system. These devices will be provided to PSAs who will be able to deal with passenger incidents and talk to passengers from the phablet if, for example, crowding makes it difficult for the PSA to move through the train to the location of the alarm.

The train

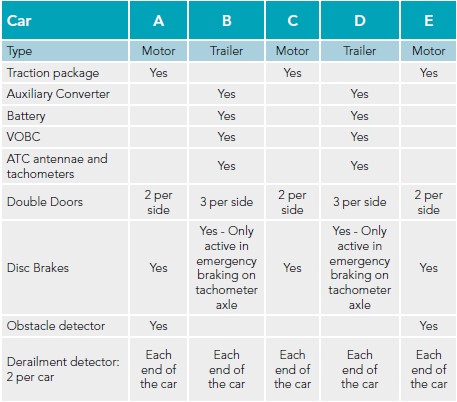

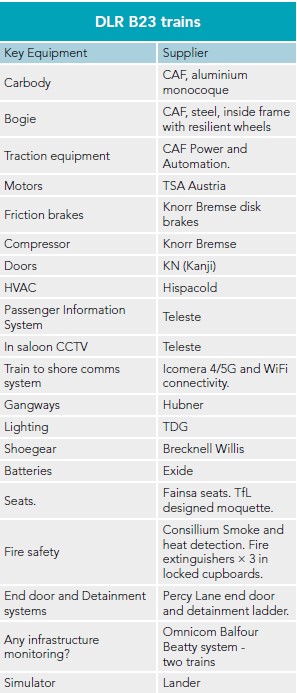

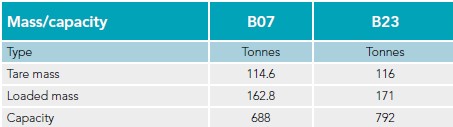

The disposition of key equipment is shown in Table 1. In practice cars D and E are mirror images of cars one and two. Table 2 shows the manufacturers of key equipment and Table 3 compares weight and capacity of the B23 trains with a three-car B07 train.

Achieving weight targets was very important as there were strict limits on some of the structures from the original ‘light railway’. Although a great deal more equipment is fitted, particularly air conditioning, and passenger capacity is higher, weight has been held in check by the switch to aluminium car bodies instead of steel used on earlier trains.

Equipment

But onto other more routine technical features. Phil emphasised the importance of redundancy and graceful failure to avoid service disruption. A stranded train that needs recovery causes much more disruption compared with one that can limp home to depot. As an example, although there are three motor cars, just one of them has enough tractive effort to propel the train up the steep gradient between Bank and Shadwell. And each motor car’s traction package has two inverters, one for the two motors in each bogie. All three motor cars have their own power collector shoes which are an improved version of the Brecknell Willis design used since DLR started. There is no power bus line. Cars B and D are each fitted with an auxiliary power converter providing three phase AC power and 110V DC for battery charging, powered from Cars A and E respectively.

Regenerative braking will be the norm but there is a naturally cooled rheostatic resistor on each motor car for conductor rail gaps and any part of the line that are not receptive for regenerated energy.

Each axle has a single brake disc controlled by Knorr Bremse’s EP2002 system. Wheelslide protection is fitted which Phil expects to be evaluated on the WSPER rig (Issue 176, July 2019) prior to service.

CBTC equipment is fitted to the trailer cars. It is the latest Thales ‘SelTrac TOP’ VOBC (Vehicle On-Board Computer). The tachometers feeding the VOBC are fitted to the eighth and thirteenth trailer axles and the antenna for transmitting/receiving data to/from track loops is adjacent. Either VOBC can drive the train and the system can switch between them seamlessly.

Unusually the tachometer axles are only braked if an emergency brake is demanded. SelTrac systems can be prone to losing position if slip/slide is detected on the tachometer fitted axle in low adhesion conditions, leading to an emergency brake application and the VOBC reporting that it is ‘lost’. When this happens, the PSA has to drive the train manually at slow speed over two loop crossovers to re-establish location, causing delay. The unbraked axles are expected to significantly reduce this issue. The guaranteed emergency brake rate is 1.26m/s2. This is the value that the ATP assumes when determining how far a train may move towards another train or obstruction.

Train control

As mentioned, the TCMS is responsible for most non-vital train control functions with hard wire control of vital functions. DLR decided that there would be two networks, one for train control functions, and a second that deals with passenger facing systems. DLR specified that the control room would have access to the on-train CCTV and was concerned that the bandwidth required for video signals could harm the response of train control commands – hence the second network.

Passenger, interior and PSA features

A big improvement for DLR passengers is air conditioning. Each car has a roof mounted air conditioner pack, and, for redundancy, given there are no openable windows, each pack has two chillers fitted. Lighting is by LEDs and each car has its own controller which can adjust the lighting level depending on the amount of ambient light and can change the colour temperature of the light depending on time of day. Each car has its own battery for emergency lighting built into the controller.

In the interests of maximising capacity, all but eight seats on the train are longitudinal, but eight transverse seats were retained, four at each end, partly to provide a semi-enclosed space for the PSA when driving manually (although they drive standing up at their request), and partly for people who like to imagine they’re driving!

There are 12 sets of passenger doors per side, two per side on Cars A, C, and E, and three per side on Cars B and D. Phil described them as low-profile plug doors which incorporate sensitive edges and anti-drag systems. They don’t close completely flush with the bodyside and, when open, project very little. When the doors are released, lights over the doors glow green and they flash red when the door close command is sent.

There is a PSA door control at every doorway, and, following human factors review, they are located at a lower level than on the older trains with half on the left and half on the right. At stations, doors are released automatically by the CBTC. The controls are the same as the older trains: close all doors except the PSA’s, reopen doors, close PSA’s door, and public address. A key-operated switch and a microphone complete the controls.

As well as a light provided on the older trains indicating that the train has movement authority (CBTC speak for a green signal!) the B23 has a countdown indicator allowing the PSA to initiate the door close sequence a little earlier. Once all the doors are proved closed and the VOBC has movement authority, the train starts automatically. Currently, the system is set up so that the doors only close after a three-second alert has elapsed. This is compliant with the Rail Vehicle Accessibility Regulations (RVAR). But it is a much longer delay than is used currently on DLR and on most of the Underground. As the shorter delay has been used successfully on DLR for over 30 years, a proposal has been made to DfT for a derogation from RVAR, like those previously granted for some of the Underground’s new trains.

Gangways

DLR has 40-metre radius plain curves, 40-metre radius back-to-back reverse curves on the service lines, and 38-metre radius curves in the depot. Providing a gangway on 17-metre-long, two-bogie vehicles, that must negotiate such small radius curves/reverse curves is a challenging requirement and, as a result, it is much longer than is usual. It was made by gangway specialists Hubner, based on a design previously used in Frankfurt, and the project team reported that it is performing well during network testing.

Passenger alarm, CCTV, passenger information

Passenger alarms are fitted in each doorway and alongside each wheelchair bay. As is usual, the passenger alarm only stops the train immediately if it is at or departing from a station. Operation of the passenger alarm alerts the PSA and the PSA can respond using the phablet or control point handset if the PSA is unable to move down the train to the customer. Passenger information includes the usual voice and visual displays. The visual displays are LCD type for the interior and LED dot matrix for the exterior and the whole system is pre-programmed with the usual messages (e.g., next station and destination) which can be varied from the control room via the 4/5G/wifi comms link. This includes the ability to display the standard TfL ‘rainbow’ board highlighting any delays on other rail lines. Additional displays are provided for advertising.

Saloon CCTV is fitted as well as cameras providing views from the front and rear of the train. The saloon CCTV cameras give views of the entire train and particularly of people using the passenger alarms. A nice feature of the forward/rear cameras is a rearwards view is displayed on the PSA’s control desk if reverse movement is selected (accompanied by external reversing beeps).

Safety features – fire

The engineering process is aimed at delivering a train that is safe by design and the sub-systems described above all include safety features, but there are inevitably some risks that need specific controls. A key requirement is fire safety, especially on a train with open wide gangways. This applies to everything on the train with the objective of minimising sources of ignition and using materials that are hard to ignite, tend to self-extinguish, resist flame spread, and produce little smoke.

The train has been designed to BSEN 45545 Operation Category 4, Design category A. Operation Category 4 refers to vehicles for operation on underground sections, tunnels, and/or elevated structures, without side evacuation available, and where there are stations or rescue stations that offer a place of safety to passengers, reachable within a short running time. Design category A is for vehicles forming part of an automatic train having no emergency trained staff on board. The combination results in the toughest requirements for fireworthiness of all materials used in the train’s construction. In addition to careful selection of materials, a smoke and heat detection system is provided, linked to the PSA and the control room, and there are three fire extinguishers on each train.

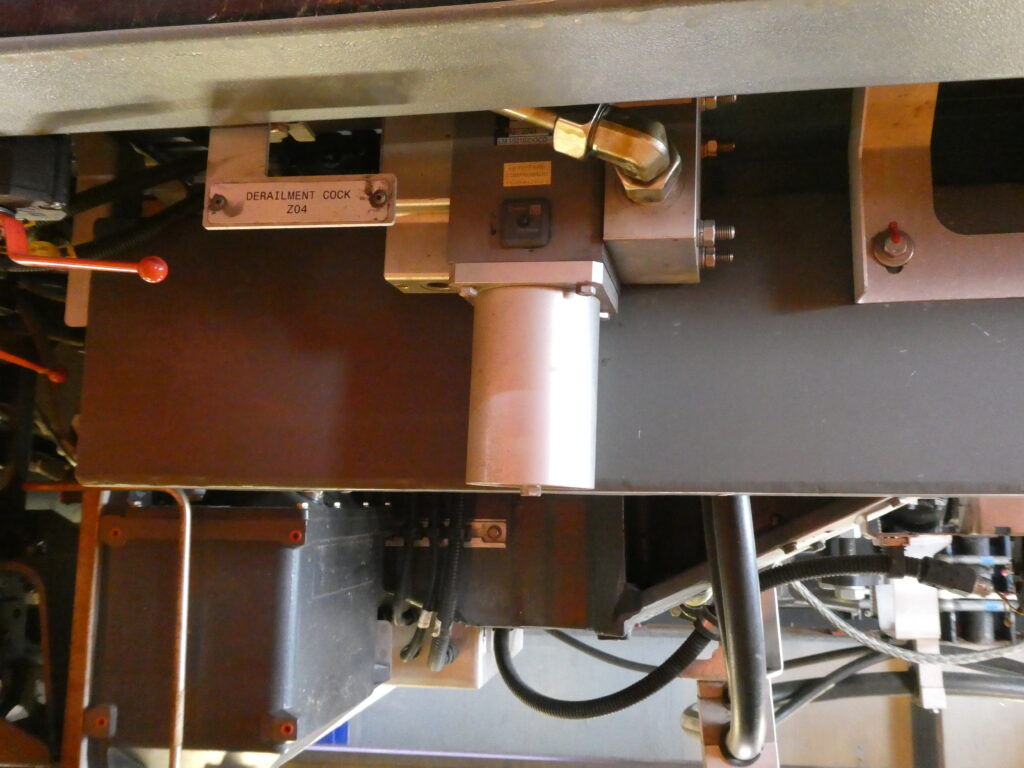

Safety features – obstacles and derailment

The combination of good bogie design, well maintained track and ATP means that derailment risk is extremely low, but not negligible. Two systems are provided to help control the risk and consequences of a derailment. DLR had specified an obstacle detection system that would ensure a train would stop short of an obstruction (similar to modern automobiles’ emergency braking feature) but it soon became clear that comparatively longer braking distances for trains and DLR’s sharp curves made such a feature impractical. Instead, there is a bar fitted in front of the leading axle that, if it strikes an object that could derail the train, it will apply the emergency brakes. While this does not prevent a collision with an obstruction leading possibly to a derailment, by applying the emergency brake the consequences will be minimised. As another precaution, an underframe mounted accelerometer is provided on both ends of all cars. This will apply the emergency brake if it detects acceleration pattern that would be seen if a wheelset has derailed.

Safety features, emergency detrainment

There is a door at the end of each end car to which a folding stair can be fitted, in case evacuation away from a station is required. Rail Engineer was told that the current record for extracting the stair and fitting it to the front of the train is just under 80 seconds.

Infrastructure monitoring

Two trains are being fitted with Omnicom Balfour Beatty infrastructure monitoring systems that will provide an important subset of routine track condition information on a much more frequent basis than is currently possible with KAD’s existing monitoring equipment. The trains will be programmed onto each route as required.

Power supply

With 20-plus extra trains, DLR is planning an upgrade to the power supply. This will also support the higher acceleration rate of the new trains compared with the old ones. While the timetable will be organised around the capability of the B2007 trains, the VOBC will be able to take advantage of the B23’s higher acceleration rate to recover the timetable if there are delays. Another power issue is the proximity of live collector shoes to the platforms. Since DLR opened, covers mounted on the platform wall have shrouded collector shoes when trains are stopped in stations. The new trains’ shoes are in different positions, so DLR has provided continuous covers at all platforms.

PSA clear view of platforms

Another external interface is cameras/CCTV monitors and/or mirrors provided to give the PSA a clear view of the platforms when driving from the front of the train. As the front end design is different, the PSA will be standing up to drive (a PSA preference), although they can be seated if monitoring ATO and controlling the doors. Mirrors and/or monitors are being provided/relocated at platform ends to give the seated or standing PSA a clear view of the PTI for both new and older trains.

Operational acceptance and training

Currently there are two trains in London, being used for testing, integration, and reliability proving. The trains have to be tested throughout DLR, and the SelTrac CBTC has to be tuned to the train as its acceleration and braking characteristics will inevitably be different from the existing trains. Reliability must be demonstrated before being accepted and a 20,000km mean distance between service affecting failures is the requirement. Of course, KAD staff – PSAs, maintainers, etc. – also need to be trained. A train simulator has been provided and there will be a test rig for the new VOBCs. DLR has placed a long-term support contract with CAF, something that will support KAD with maintenance, spares and technical support.

To conclude, the October TfL Commissioner’s report to the TfL Board says that TfL is preparing for the launch of the new trains, and continues with depot enabling works, new train testing at times of closure, and preparation for testing in between passenger trains. Entry into service is forecast for March 2024. At the time of writing, the 25th train was nearing completion.

Photos courtesy of TfL unless credited otherwise.

DLR/KeolisAmey Docklands

DLR/KeolisAmey Docklands DLR is operated on a concession model. TfL/DLR owns the infrastructure and rolling stock, but it lets a contract for the maintenance and operation of the railway. The current concessionaire is KAD which has held the contract since 2014. In legal terms, KAD is the Train Operator and Infrastructure Manager for the stations, with TfL as Duty Holder for all the other infrastructure. The contract is due to end in 2025 and TfL has recently commenced the procurement process for the next concession. The changeover date is in April 2025, before all the new trains will be in service, so the handover process will have to take this into account.