Rail Engineer described the outline design of London Underground’s forthcoming new Piccadilly line trains (2024 tube stock) in issue 190 (June/July 2021). Since then, Siemens or TfL have occasionally issued press releases showing progress with first bodyshells or mock-ups.

On 1 August 2023, Siemens announced that the first complete train had arrived at its 44-hectare Test and Validation Centre in Wegberg-Wildenrath from its Vienna factory, ready to start type testing. In November, Rail Engineer visited Wildenrath to try out the new train. It had been positioned on the inner test circuit, a dual gauge (standard/metre) oval 2.45km long, equipped with overhead line, underneath contact third rail, which had third and fourth current collection rails added for 2024 tube stock.

This article focusses on some of the train’s technical details, and the result of turning 3D renders or mock-ups into the real thing.

To recap, this is a nine-car train with bogies under five of the cars with the other four cars supported between them. The design allows all double doors, walk though gangways, and air conditioning: all passenger facing features that were the raison d’etre for this innovative design. Compared with a conventional seven-car train of the same length, it is lighter and, with just 10 instead of 14 bogies, there is more under-floor space which was vital to accommodate air conditioning equipment.

Collaboration

When Rail Engineer interviewed Dave Hooper, Siemens Mobility’s Director of Major Programmes, in 2021, he was full of praise for the way in which the Siemens and TfL teams worked together. Two years on, Dave, together with Sambit Banerjee, joint CEO Siemens Mobility UK, Stuart Harvey, chief capital officer TfL, and Steve Ristow, head of delivery, Fleet Introduction, paid tribute to the ongoing close collaboration and the objective of delivering a train that meets all of TfL’s aspirations on time and to budget.

This year, Rail Engineer has attended several events where collaboration was seen as the solution to problems or the way forward. Occasionally, as here, collaboration has been baked into the relationship from day one, with obvious benefits to the project.

2024 tube stock progress

Approaching the train, two things were immediately obvious. First, it looked awfully small set against European gauge trains, especially double-deckers. Second, there were red light strips glowing above each closed door and a green strip above the open door. The red strips stayed lit when moving which, Rail Engineer understands, is not the final configuration. Stepping into the train led to more surprises. The lighting – all LED from Yorkshire-based LPA Lighting Systems – was bright, even in daylight. Very unusually for a tube train in the open on a cold November day, it was warm, and the designers have managed to provide more headroom, no mean feat within the tight gauge of the London small gauge lines.

Inside, it is clearly a tube train with traditional painted poles and rails and a new moquette design (named Holden, a tribute to the architect of many Piccadilly line stations). Details from the original Priestman Goode proposal from many years ago survive, including a metal TfL roundel on each seat riser. The small windows, provided to allow space for air conditioning ducts, echo the 1938 tube stock and there is a particularly neat looking circular LED lamp surrounding the grabpole in the centre of each doorway. The seats are all longitudinal with some tip up seats in every car. The seats have been designed to encourage people to sit upright, but it would be an exaggeration to say they are soft; they offer a similar level of comfort to most modern tube train seats.

Above the windows, where one would normally find cardboard adverts, there were LED screens which on this train were showing journey progress towards Heathrow Airport. External information displays are white LED strips.

The train had been rigged for dynamic testing to demonstrate acceleration and braking functionality along with noise and vibration trials. This meant that only the leading car was completely clear of test apparatus and wiring; the rest of the train was closed off by a mirrored door.

Another feature is wide doorways, although the individual door panels themselves are not as wide as on previous tube stock as the door operating mechanism is in the roof, not on the car side. These are equipped with sensitive edges, similar to the provision on the most recent TfL tube trains.

There is a small ramp down to the cab. Piccadilly line drivers will find their ‘office’ more spacious than their current cabs. As the driver sits further back from the windscreen for both comfort and crashworthiness reasons, the field of view is a little more restrictive, so some alterations to signals will be necessary for this reason and also to accommodate the longer train (113m, compared with 1973 tube stock at 106m).

From the outside

Looking round the outside of the train, the prominent white marker strip light around the cab front is supplemented by two extremely small but very bright headlights. TfL has also departed from the traditional Wedgelock mechanical coupler in favour of a Dellner type for emergency and recovery use. There is not enough space above the coupler for the usual centre anti-climb buffer, and side anti-climbers are used instead. Safety arrangements at Wildenrath precluded a detailed look underneath the train, but the inside frame bogies were clearly visible showing Brecknell-Willis shoegear, Faiveley brake cylinders, solid stick wheel flange lubricators, and wheel/rail sanding applicators.

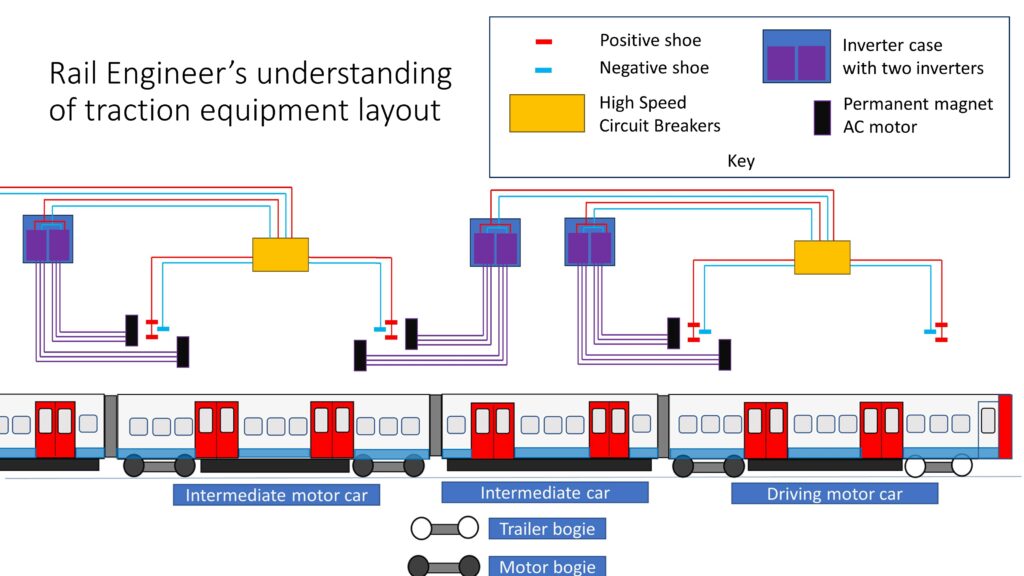

All the bogies carry shoegear except the motor bogies on car five in the centre of the train. It was also possible to see the large centre coupler that connects a bogie car to a bridge car. The couplers are designed to allow roll, pitch, and yaw movement. If roll was uncontrolled, the intermediate car would be unstable, so one end had a roof level lateral control rod connected to the adjacent motor car. The tray supporting the compressed air supply and the many electrical connections is supported by the coupler. As the couplings do not have to accommodate lateral or vertical relative movement between cars, gangways are relatively short. This configuration has led to some clever equipment layout solutions involving shoes on all but the centre motor car, whilst the inverters (one per motor) are on the intermediate (bogieless) cars as the diagram illustrates.

Siemens’ climate chamber has been used to assess the performance in extreme weather conditions. It delivers realistic and repeatable climate conditions with which to assess whether the air conditioners cool, heaters heat, and whether all the equipment continues to operate in hot, cold, dry, wet, and freezing conditions. Tests focused on the effects of extreme ambient temperatures from -15°C to 40°C, solar load of 600W/m2, ice, and high wind speeds of up to 100kmph, to check the train can still operate in extreme weather conditions. Monitors were used to understand what passengers would experience, measuring humidity and temperatures in the cars.

The ride around the inner circuit was smooth and quiet. Rail Engineer thought the train was riding on air suspension before remembering it uses rubber springs. Overall, it is a compliment to say that this first train is a faithful realisation of the design concepts, with an overall feel of solidity.

Programme

Sambit Banerjee and Stuart Harvey outlined the programme for the next few years. Following type testing at Wildenrath, the first train is expected to be delivered to London (through the Channel Tunnel) for infrastructure integration testing in summer 2024, with entry into service due in 2025. Stuart said he expected to be able to withdraw the last 1973 tube stock train in 2027, and the last new train might be delivered a few months later. Although the original contract provided for about half of the trains to be made at the new facility in Goole (issue 104, September/October 2023), Sambit indicated that a higher proportion might be made there depending on meeting delivery timescales for TfL.

The first carbodies are due in the UK in March 2024 when manufacturing will commence for the Piccadilly line trains at the Goole factory. For further support, work has just started on a new joint venture parts warehouse on an adjacent site.

What next?

Stuart Harvey explained that the Bakerloo line trains (1972 tube stock) are even older that the 1973 tube stock, and whilst safe, are increasingly suffering from poor condition and obsolescence. He said:

“The most important thing now is that we are making the case to Government for the vital long-term capital investment we need to continue with improvements like this, which support jobs and economic growth. We want to follow the introduction of these new trains on the Piccadilly line by doing the same on the Bakerloo line, replacing the 51-year-old trains that it currently operates, and by continuing to modernise our fleets and signalling to make sure they remain safe and reliable. Such vital improvements will not be possible without continued capital investment from the Government from April 2024.”

Sambit Banerjee added that that all future UK orders including the Bakerloo line trains would be built in Goole.

Even if ordered immediately, Rail Engineer understands that none would be in service before 2028, by which time the 1972 tube stock would approaching 56 years old, an unenviable record for trains in front line daily operation. This is about 20 years beyond their original design life for which there is no real precedent, making it hard for engineers to be confident that the trains can continue running.

If nothing is done, the Bakerloo service will gradually decline. Although TfL has identified an option to carry out a costly condition improvement programme, which would extend the life for another 10 years, the costs are uncertain and new trains would have to follow. It is an expensive option compared with new trains.

Stuart explained that the current contract has a costed option for new Bakerloo line trains which must be exercised by the end of 2026, adding that TfL is seeking £500 million from government to support its capital programme. Although 2026 is the latest date for ordering the trains, Stuart said that TfL needs the go-ahead as soon as possible as extensive infrastructure works are needed to accommodate the new trains. These changes include:

- Expansion of Stonebridge Park Depot to accommodate more trains and this train design where it is not easy to split the train into individual cars.

- Station works to fit new CCTV cameras and transmission system to give a clear view of the platform train interface to a monitor in the driver’s cab.

- Works to the power supply to accommodate higher peak demand and regenerative braking.

- Changes to the signalling to accommodate different sight lines.

Conclusion

Showing off the first train of a fleet is always a good way of gauging progress. TfL and Siemens are clearly confident in the new train and by having options in their contract for more are in a position, with what is effectively an ‘oven ready project’ (to coin a phrase used by a previous London Mayor), to press ahead rapidly if funding can be made available. This funding would demonstrate confidence in London and in the East Riding of Yorkshire.

With thanks to Siemens Mobility’s Katie Byrnes for her assistance with this article.

Bakerloo line fleet, a personal perspective

I was involved with commissioning the 1972 tube stock in around 1973, shortly after finishing my training with London Transport. Thirty trains (mark 1) had been bought to replace some of the 1938 stock on the Northern line which had been dubbed ‘the misery line’. Soon after Metro Cammell said that there would be a gap in production before the Piccadilly line 1973 stock was built, so the government agreed to the production of 33 trains (mark 2) for the recently authorised Fleet line (now Jubilee line). The trains were originally put to work on the Northern line allowing more old trains to be withdrawn.

Over their lives, this fleet of 63 trains worked on the Northern, Jubilee, and Bakerloo line. They were refurbished in the early 1990s which entailed being hauled across the Forth Bridge to the Royal Dockyard at Rosyth. Whilst most of the mark 1 trains were withdrawn in the late 1990s, a few were modified to work with the mark 2 trains and to replace accident-damaged cars.

The Bakerloo line contains a large number of small radius curves and constant operation over these gives the running gear, bogies, underframe, couplings, etc, a hard life. By the time they were about 40 years old, it was apparent that they might have to keep running until the 2020s and it was my team that proposed a series of repairs to keep them going.

Authority to carry out mechanical repairs to the body and underframe was granted, although the sum had to be increased as the vehicles were in a worse condition than had been found during the initial survey (issue 141, July 2016). Since then, further modifications have been carried out to comply with the Rail Vehicle Accessibility Regulations and to refresh the interiors which were largely unchanged since the early 1990s refurbishment. The works covered in the 2016 article were intended to extend the life to circa 2026.

Even if new trains are ordered immediately, there is no prospect of them being in service until about 2028. Already the Bakerloo line service has been reduced slightly because of unavailability of trains. Replacement is urgent. Could there be further life extension? Probably, but it would involve spending a lot of money on worn out parts and engineering replacements for those that are obsolete. There would also need to be continuing risk assessment to ensure the safety of these trains and it is hard to be conclusive about risk or future life when there’s little or no prior experience of running such old trains in squadron service. The risk is that there might be a significant reduction in service, or, in a worst-case scenario, the Bakerloo line has to cease operation altogether.