The Unlocking Innovation events hosted by the Railway Industry Association (RIA) are always of interest and their RailDecarb21 workshop, held in Glasgow on 13 October, was particularly topical as it was held just over two weeks before COP26.

While the focus was on reducing carbon, in her keynote address Jo Lewington, Network Rail’s Chief Environment and Sustainability Officer, emphasised that sustainability required more than this. She stressed the need to improve biodiversity as required by Network Rail’s Environmental Sustainability Strategy as she considers the risk of biodiversity collapse as greater than that of climate change.

Network Rail’s Sustainability Strategy Manager in Scotland, Wendi Wheeler, described the action being taken to meet Scotland’s Railway target of no net loss of biodiversity across Scotland’s railway by 2024. Scotland is also now taking action to decarbonise its passenger services by 2035 and ensure net zero emissions for all of Scotland’s Railway by 2045.

The three options

Three parallel workshops considered electrification, battery and hydrogen traction. An advantage of the hybrid event was being able to watch videos of the two workshops not attended on the day.

The first presentation in the electrification workshop was by Richard Fluin of Arcadis who considered the costs and benefits of overhead line systems. His presentation showed how the 25kV AC system is currently the most economical system with a return on investment that can be easily reached on busy lines. It also showed that total infrastructure and rolling stock cost of an electric railway is two-thirds that of a diesel railway with electrification halving the costs of both rolling stock maintenance and energy.

Allowing freight trains to be electrically hauled all the way into freight terminals was considered by Noel Dolphin of Furrer+Frey, who is leading a pilot project that has a moveable overhead conductor bar to permit unloading. Denzel Collins, a Network Rail Environmental Specialist is working with the Riding Sunbeams initiative to provide an energy storage for 750 Volt DC 3rd rail systems to store energy from intermittent renewable sources and improve receptivity for regenerative braking. Dr Pedro Antunes of the University of Huddersfield’s Institute of Railway Research described the institute’s pantograph test rig and explained how tools to simulate complex pantograph-catenary interaction had been developed.

With increasing use of batteries in all sectors, the Knowledge Transfer Network (KTN) is creating a cross-sector battery system innovation network. Dr Abi Hird, KTN’s battery systems network lead explained how an online platform (www.ukbatteriesnetwork.org) had been created to promote this. This has a webinar on battery opportunities for rail which shows that battery costs for rail are typically £2,000 per kWh, 10 times the cost of automotive batteries.

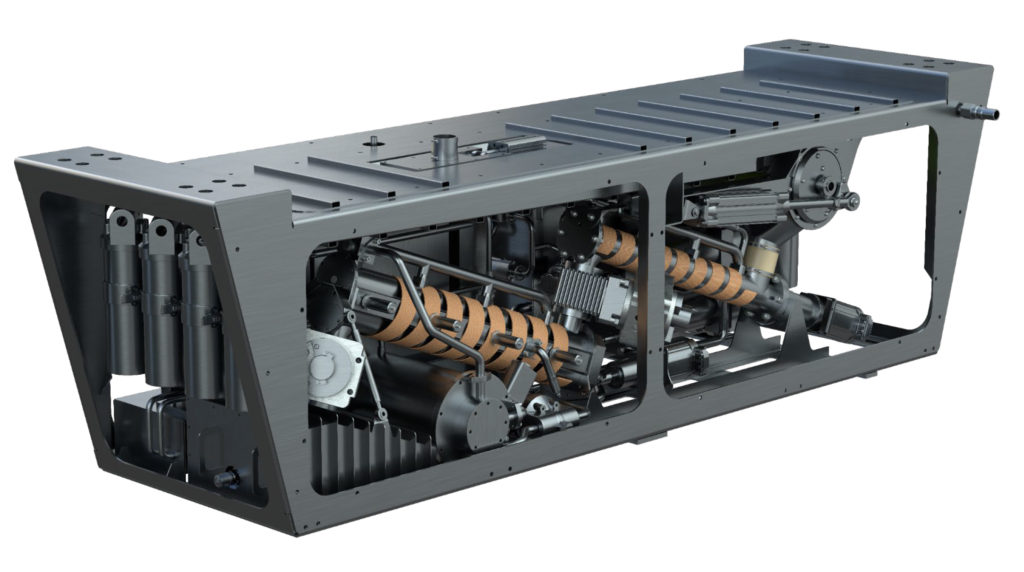

The hydrogen workshop had presentations from Jon Constable of Tpgroup, Richard Kemp-Harper of Arcola Energy, Kevin Fothergill of EnAcumen, and Luke Johnson of H2Green. These showed how Tpgroup had used their experience of submarine atmospheric management to develop fuel cells for the Hydroflex train and how Arcola were installing their A-Drive hydrogen drive train in Scotland’s hydrogen train. Presentations from EnAcumen and H2Green considered the issues associated with the production and transport of hydrogen and options for its storage, including Ammonia.

Reducing non-traction carbon

Construction and electric vehicles were considered by two presentations. Costain’s Group Climate Change Director, Lara Young explained the need to prioritise while having clarity of the whole picture. Costain’s climate change action plan prioritised construction plant, low carbon materials, vehicle fleet decarbonisation, and energy use of accommodation.

A systematic approach to make the best use of depots when introducing electric bus fleets was considered by Mike Nugent, Hitachi’s Head of Electric Vehicles. He explained that applying this approach to a particular Network Rail depot would require an investment of £2.8 million which would pay for itself in six years and save 380 tonnes of CO2 per year.

The importance of embodied carbon was stressed in three presentations. Jamie Pitcairn of Ricardo explained that, with only 10% of UK manufacturing emissions occurring in the UK, life cycle assessment is needed to fully evaluate embodied emissions. Victoria Eggleston of Arcadis explained how useful the RSSB’s rail carbon tool was in this respect. She showed how carbon could be reduced by careful analysis of concrete grade for cill units and the thickness of steel elements. Finally, Dr Saran Sohi of Edinburgh University described greenhouse gas removal technologies for linear infrastructure projects.

Elevator pitches

Short presentations showcasing products and services were given by:

Dan Cutting of the Driving Electric Revolution Industrial Centre, which provides support for the development of power electronics, machines and drives.

Natalie Cartwright of GBR-Rail Ltd, which has developed the ClearTrack sustainable sink and toilet waste treatment system that purifies and recycles liquid waste. The system only needs emptying every three months, is lighter, and has a lower energy consumption than conventional CET toilets.

Rupert Stevens of Dynex, which has 60 years’ experience of power semiconductors.

Gary Sanford of Scott Parnell, whose Flex MSE stacked bag retaining walls system has 97% less embodied carbon than concrete and can be installed at around 60% of its cost.

Dr Will Midgley of Loughborough University whose control systems group has undertaken studies to determine emission savings from electrification.

It was an intense and useful day which offered much food for thought. Thanks to RIA’s Sam Bemment, Karl King and Milda Manomaityte who did a good job of managing the intricacies of this hybrid event. Do look out for RIA’s 2022 programme of Unlocking Innovation workshops which are ‘must attend’ events for anyone with an interest in rail innovation.