The cost of signalling in the UK rail industry has been a concern for many years and signalling renewals are a major cost for Network Rail at around £200 million a year. There is also a huge renewals programme required across the network, with some signalling assets over a hundred years old. How old do you think is the oldest signalling interlocking still in operation on the network today? We shall tell you at the end of this article, but a clue is that many museums have signalling assets on display which are newer than some still in use on the main line network!

An Office of Rail and Road (ORR) market study carried out in 2021 found that the market for major renewals in Britain is dominated by Siemens and Alstom, and the ORR had concerns over the value for money of signalling and the ability of new players to enter the signalling market.

However, this is starting to change, and Rail Engineer recently visited Sella Controls’ Rail Support Facility in Coalville to learn of its new Commercial Off the Shelf (COTS) Programmable Logic Controller (PLC)-based signalling being developed in collaboration with Amey Consulting. This has resulted in Network Rail approval for the Amey Consulting-configured Hima HIMatrix Manually Controlled Barrier (MCB) level crossing.

The approved product is the result of seven years of ‘in house’ investment and R&D by both Amey Consulting and Sella. As the Hima PLC safety expert, Sella developed the early-stage concept and logic, and provided expert advice to Amey Consulting on best practice, alongside supporting activities such as problem solving, code walkthroughs, and programme reviews. But the level crossing is only one of the modern COTS safety PLC solutions that has been developed over the past few years through open-innovation and successful collaboration between the two companies.

Expensive but safe

British signalling may have a reputation for being expensive, but it is very safe and generally reliable. For example, there are just under 5,800 level crossings in use on the mainline rail network in Britain with another 1,500 in use on heritage and minor railways. Many of these use old technology and methods of working, but level crossing incidents in the UK are well below the European average. The total number of persons killed by level crossing accidents per 100,000 population is 1.18 in Hungary, an average of 0.345 throughout Europe, and 0.02 in Britain. So, any new system and supplier must be able to meet the stringent design and verification and validation requirements for safety critical signalling control systems.

Amey Consulting has many years’ experience of Britain’s signalling principles and stringent design requirements. It is also keen to introduce new equipment, innovations, and ways of working to reduce costs and increase efficiency, by using standard products and tools that are commercially available, rather than expensive bespoke signalling technology. The current UK signalling market is currently one where the equipment supplier is generally the system integrator. Amey Consulting’s mission is to encourage a more cost-effective choice of equipment and interoperability for the signalling market.

Amey Consulting wants to learn from other industry sectors, such as utilities, power generation, aviation, and defence. The rail signalling industry has a tendance to think it is different and unique to other sectors. However, many other sectors also have safety critical requirements. With a railway you can shut a route to perform work and upgrades, but in some other sectors the control systems can never be turned off and must always be 100% available. The railway doesn’t have a monopoly on good ideas and lessons can be learned from other sectors. Often, other industry safety sectors have access to R&D resources which are far greater than those of traditional rail signalling companies.

Therefore Amey Consulting, Sella Controls, and Network Rail have been working together to introduce technology from safety industries outside of rail and to provide really cost-effective, competitive, and novel signalling solutions. Hima Group of Germany, which specialises in safety-related automation solutions, acquired UK Sella Controls in February 2023. Since the acquisition, Hima has established Sella Controls’ Coalville and Ashby offices as its ’Centre for Excellence for Rail Solutions’. Hima has provided safety control systems technology for many years and its systems are used in controlling UK, French, and German nuclear plants. Its PLCs are also used in numerous safety applications including oil and gas, chemical plants, and railway signalling applications in many countries throughout the world.

Sella Controls is an independent engineering company specialising in the design and supply of integrated safety, control, and automation systems. It has access not only to Hima’s safety critical products, but also to other suppliers of the best state-of-the-art control products throughout the world. Sella’s systems can be found in highly complex and often hazardous environments within a variety of industry sectors.

The company is not new to rail and, for example, has been providing Station Information and Security Systems (SISS) for many years, including information displays, closed circuit television, long line public address, induction loops and passenger help point technologies. Its scope has included complete end-to-end project delivery from consultancy, detailed design, build, and final installation and commissioning. Its clients include Network Rail, London Underground, and a growing number of train operating companies.

Heart of the system

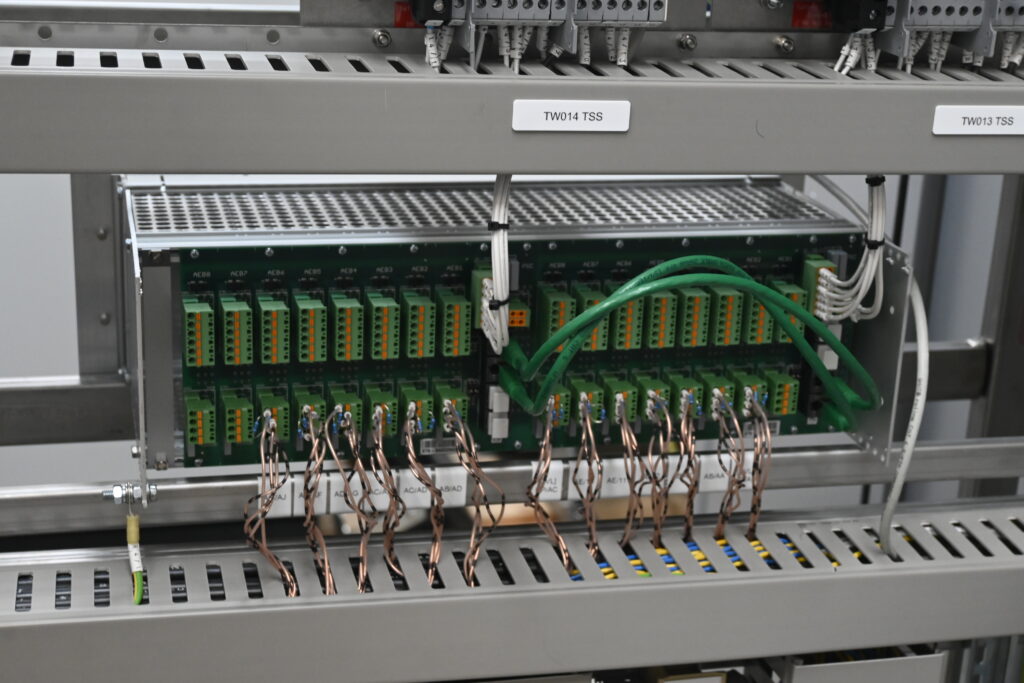

The heart of the signalling control systems currently being tested at the Rail Support Facility is the SIL 4 PLC supplied by Hima. The unit is compact and modular with network capability via Ethernet and serial input / output, and it can be used as a standalone device or in distributed applications. SIL 4 (Safety Integrity Level 4) in Standard IEC 61508 is the highest level of safety integrity and represents the level required to avoid disastrous accidents. Amey Consulting (with the support of Sella) has built upon this to achieve full SIL4 certification at the application level and achieved assurance to comply with the CENELEC ‘Functional Safety for Rail’ Standards (EN 50124, EN 50128, and EN50129).

Hima’s range of PLCs have a long and established safety pedigree and provides significant improvements over current signalling technologies. The PLC is programmed and configured using the modern and easy-to-use Hima SILworX engineering tool. This uses an intuitive drag-and-drop interface to manage and configure the controllers as well as the remote input/output systems. Error diagnostics, using the same interface, result in fewer user errors and enable integrators to commission safety systems more quickly and adapt to new requirements.

To compliment SILworX, Amey Consulting has also developed the Amey HIMatrix Applications Manual along with the tools and techniques to satisfy the Network Rail Signalling Design Handbook (SDH), and the Signal Works Testing Handbook (SWTH) requirements for railway signalling applications. These have been developed in such a way that signalling designers and testers will find it easier to transition from traditional railway signalling control systems to the novel PLC based signalling. The Hima COTS PLC also uses safeethernet, a transmission protocol based on standard Ethernet, but which also fulfils SIL 4 requirements.

Systems under test

The Taffs Well depot control system was undergoing extensive testing at the Coalville centre for installation later this year at the base for Transport for Wales’ (TfW) new fleet of Citylink Trains. The depot system consists of a fully redundant central interlocking PLC, connected to five distributed location cases delivering a SIL 4 Depot Control System (DCS). This is integrated with Frauscher Axle Counters to provide train detection and the control of points, and the distributed approach provides a significant reduction in installation costs. Once installed, the system will present the depot layout and control via a modern signallers display in the new Taffs Well control room. This is also based on standard COTS components and appears to look like a typical Network Rail signaller’s display, but it also uses pull down menus and windows, similar to a standard computer, making it easier to train people new to rail.

The DCS solution is flexible in its design to enable control solutions for SIL 2, SIL 3, and SIL 4 applications as appropriate. This is important as SIL 4 is expensive and complex, and making everything SIL 4 results in over engineering and unnecessarily increases the cost of signalling.

Sella Controls was also testing its SIL 3 Independent Emergency Shutdown System for Iarnród Éireann – Irish Rail’s (IE) electrified network. This is also a modern COTS-based solution to safely and independently shutdown and isolate the railway in an emergency. The scope includes the complete safety design, engineering, build, installation, and commissioning of the solution. It uses the Sella Controls’ Tracklink® product suite and the Hima HIMatrix Safety PLC.

The system features a fully redundant safety PLC architecture across 21 locations delivering a SIL 3 safety shutdown and isolation system for traction power. This system will be completely independent of the main power control system, preventing the energisation of power during an isolation or emergency shutdown. The contract also includes the supply of Sella Controls’ Tracklink SCADA application to provide operator and maintainer workstations to monitor system performance, event analysis and data exchange with the existing traction power SCADA System.

Tracklink Remote Terminal Unit (RTU) for traction power substation control and automation has also achieved full Network Rail Product Acceptance for electrification control and substation automation. Tracklink RTU is the result of a partnership between Sella Controls and Mitsubishi Electric using their COTS PLC. The first installation went live in January 2016 at West Ham Feeder Station on the Anglia route and since then it has been deployed across the UK rail network for Network Rail, Transport for London, and Docklands Light Rail. This has also been deployed for tunnel ventilation control and other safety related systems. As part of the HS2 enabling works program, Sella also recently installed a Tracklink solution at Euston to provide substation automation and control. This consists of a fully distributed solution across four substations for both remote and local control as well as auto reconfiguration of power around the site.

Level crossing PLC

The PLC signalling level crossing control system has been approved following successful trial at Magdalen Road level crossing in the Anglia region. The approval is initially for a Manually Controlled Barrier (MCB) level crossing using relays for lamp proving, but this is likely to be easily extended to cover other level crossings, such as MCB CCTV, MCB Obstacle Detector, and Automatic Half Barrier (AHB). Both parties have invested significant time and money in developing the system in collaboration. This process began several years ago when Mark O’Neill, Amey Consulting technical director signalling and Sella Controls’ former business development director Iain Wilkinson (now retired) sensed an opportunity for innovation and commenced R&D activities. The Network Rail approval requires that the level crossing HIMatrix PLC installations are designed, verified, manufactured, installed, tested, and validated in accordance with the Amey Sella HIMatrix Applications Manual.

The Hima PLC is easily programmed using standard languages, with no specialist railway-specific training required and the safety case has been developed to provide open access to the technology for other signalling suppliers and consultants that do not have such technology of their own. Therefore, other signalling companies will be able to use the applications manuals and safety approach developed by Amey Consulting via a licence arrangement. The new AHB concept is configured using a simple spreadsheet and designed so it can be installed by any supplier. This could even include Network Rail’s internal works delivery organisation to further reduce the cost of level crossings. The COTS PLC is located in a single equipment location, rather than in an equipment room like traditional level crossing control systems, to further reduce costs.

Amey Consulting says it is a signalling solutions provider, rather than a technology supplier, and it is in its interest to introduce COTS technology so it can develop the most cost-effective solutions for clients. It sees the level crossing COTS PLC safety technology as one example of the way forward for the signalling industry, introducing modern technology, innovation, and open access, to reduce the costly supplier monopoly that currently exists in the signalling industry. “As long as the main equipment suppliers are also the main system integration and implementation contractors, there will be limited competition,” said Mark.

Other developments

Amey Consulting and Sella Controls have also developed other signalling concepts for the PLC, including a replacement Frequency Division Multiplexing (FDM) system, tokenless-block system, safety transmission system, Train Protection and Warning System (TPWS) enhancements, and a universal object controller to replace trackside Solid-State Interlocking Trackside Functional Modules

(SSI TFMs). The low power consumption provides a more carbon-friendly and sustainable PLC solution which can also work with an off-grid power supply, and it has been tested with wireless networks in Europe to avoid the need for long fibre runs.

Amey Consulting has also developed a digital railway solution using the Hima COTS PLC architecture, which has been interfaced to the Indra Radio Block Centre using the EULYNX protocol. EULYNX is a European initiative to standardise interfaces and signalling systems, with the goal of significant reduction of the lifecycle costs. This will also help mitigate equipment obsolescence and will not lock in infrastructure managers to one supplier. The very competitive mobile telecoms industry is also doing something similar to EULYNX with its Open intelligent Radio Access Network (O-RAN) initiative, so it’s an area where Amey Consulting and the rail industry are not on their own.

There is much to learn from other industries, but it has to be done very carefully by people who know what they are doing. Competition is important in driving engineering innovation and creativity at an affordable cost. However, this needs to be handled appropriately to incentivise the right outcomes and provide systems that are safe, reliable, and can be supported throughout their lifetime. Amey Consulting and Sella Controls have established the right framework to achieve this, combining Amey Consulting’s knowledge and experience of signalling principles and applications, and Sella’s specialisation in the design and supply of integrated safety, control, and automation systems, in highly complex and hazardous industry sectors. Sella also knows all about working in the rail industry.

Now, to answer the question about the oldest signalling interlocking still in use on the British rail network: Monks Sidings in the North West was provided in 1875 (yes, that’s 1875 and not 1975). This illustrates the huge requirement for new modern, safe, and cost-effective PLC based control systems.