The Great British Railways Transition Team (GBRTT) has called for evidence from all interested parties to help shape its strategic plan, to learn the lessons of the past and meet the challenges of the future. The UK Government has developed five strategic objectives for the Strategic Plan over the next 30 years: meeting customers’ needs; delivering financial sustainability; contributing to long-term economic growth; levelling up and connectivity; and delivering environmental sustainability. GBRTT’s call for evidence document asks 18 specific questions relating to the delivery of these objectives.

Together with fellow writer, Malcolm Dobell, I was invited to join the team preparing the response of the Institution of Mechanical Engineers (IMechE). The thrust of this response, which has yet to be finalised at the time of writing, is that the creation of Great British Railways (GBR) will enable a truly whole system perspective.

Engineers are there to help the railway deliver customer requirements by providing sufficient capacity, performance, and facilities in a sustainable, safe, and cost-effective manner. In addition, they should support strategic Government objectives such as decarbonisation and economic growth. IMechE has no doubt that a whole system approach will enable railway engineers to make a better contribution that will lead to more economic, efficient, and even safer solutions. Some of the engineering issues that inform its response to GBRTT are shown below.

Skills

The Williams-Shapps report rightly points out that the current railway structure makes it difficult for staff to understand how their roles relate to others in different parts of the industry. This limits the opportunity for whole-system, high-performance, efficient solutions to emerge.

A system-wide workforce strategy and plan is needed to ensure that GBR is resourced to meet current and future needs. All disciplines within the railway need to work closely together to deliver the best possible capacity and performance. To do so, it is important that everyone understands how their role impacts on others.

Merely delivering a solution compliant with standards within an individual’s own discipline does not necessarily deliver an optimised whole. Hence, there needs to be a strong cross-functional element in training and development plans. For example, the Connected Leaders Scheme (launched in 2020) is equipping future leaders with a deeper understanding of customer needs and a better cross-sector perspective.

Rolling stock, infrastructure, and timetables

In the current railway engineering structure, Network Rail is responsible for infrastructure maintenance and upgrades, with train operators responsible for rolling stock provision, maintenance, and modification. There have sometimes been significant disconnects between programmes and little effort to do anything other than the minimum infrastructure change to accommodate new trains. An exception to this was the Thameslink programme that included civil and system infrastructure changes to deliver a significant capacity upgrade provided by a new fleet of trains.

The introduction of programmes such as electrification and digital signalling require rolling stock to be modified or new trains procured in alignment with infrastructure delivery. In some cases, rolling stock priorities might drive the urgency and type of infrastructure interventions. As an example, in Scotland the immediate need to replace diesel trains in Fife resulted in a transitional solution of partial electrification and battery electric trains. This is part of the integrated plan that is now being delivered to decarbonise Scotland’s railway by 2035.

As well as aligning procurement and programmes, it is also an opportunity to integrate improvements in performance or other important capacity or connectivity work. This was not done during the Great Western Electrification programme as this did not include freight gauge clearance. As a consequence, rail freight to Wales remains restricted.

All the above demonstrates the need for an integrated rolling stock, infrastructure, and timetable strategy.

Avoiding boom and bust

The costs and skills issues of the UK’s boom and bust approach to rail electrification has been highlighted by the Railway Industry Association (RIA). This has also been a significant issue for rolling stock procurement. Between 2016 and 2021, around £11 billion was invested in 7,000 rail passenger vehicles. In the previous six years, less than 1,000 vehicles entered service.

The recent glut of train orders was for more than half the UK fleet and resulted in 4,000 vehicles being surplus to requirement, many of which were serviceable trains and some of which were electric trains for which there was no electrified railway. Most of these new train fleets were late and suffered teething problems. Many of which were related to the industry’s capability to deal with so many new trains entering service at the same time. The unnecessary costs associated with procuring such a glut of trains is likely to be a significant percentage of their cost i.e., of the order of around £1 billion.

Maximising capacity

Whatever the future timetable requirements, high capacity will always be required on core-routes to provide the required connectivity and accommodate freight and modal shift. Although digital signalling can provide some benefit, capacity on a mixed traffic railway is primarily constrained by train performance and infrastructure limitations. Improving capacity thus requires a whole system approach.

Issues that need to be considered include ensuring that, as far as possible, all trains have the same performance. In practice this requires electrification, especially for freight trains. Although the resultant capacity benefit from electrification is an important part of its business case, this benefit was not quantified in Network Rail’s Traction Decarbonisation Network Strategy (TDNS) as it can only be quantified on a case-by-case basis.

Freight trains require loops to accommodate full length, 770 metre trains with reasonable turn out speeds that minimise impact on capacity. A mixed traffic railway would also benefit from freight trains with better acceleration.

Engineering access

When and for how long to close the railway for infrastructure work is a complex trade-off between train revenue and customer needs against the engineering cost of different access windows. GBR provides the opportunity to optimise such access by considering all relevant factors in a manner that cannot be achieved under the current relatively crude Schedule 4 penalty payment regime.

Innovation

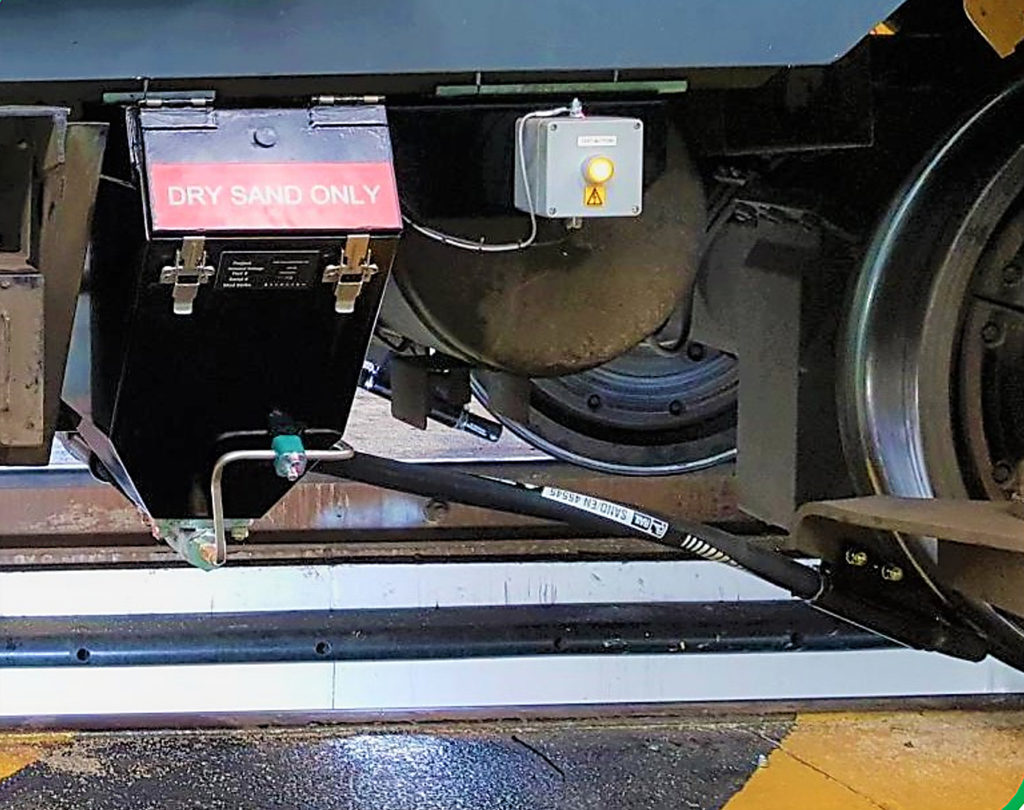

Under the franchise regime the adoption of innovations on trains was limited by the relatively short payback period. As an example, there was no demand for an innovative, fuel-saving transmission with just a four-year payback because of the length of the TOC franchise. An even bigger impact would be realised if the Double Variable Rate Sander (DVRS) system was installed on the UK’s multiple unit fleet. This would transform performance in autumn conditions; something that costs the railway around £100 million per year. It was first demonstrated in 2017 and yet the contract for the first fleet fitment was only placed in early 2022. This is an example where current incentives are unaligned.

Network Rail is responsible for adhesion issues, yet the cost of equipping trains with DVRS currently falls to TOCs or ROSCOs, although applications can be made to the NR Performance Improvement Fund. GBR should explore incentivising such innovations and, in particular, transitional decarbonisation initiatives that also offer fuel savings. However, although profitable, such investments will require funding which may not be available from the public purse. GBR should pursue opportunities for private financing of such initiatives.

Fundamentally, GBR provides a system-wide optimisation opportunity to unlock innovations across the current contractual train/infrastructure divide.

Customer service

Providing customers with improved ticketing and information is one of GBR’s key objectives. Freight customers also require better systems to plan their operations and track shipments. GBR provides the focus for the development of customer-focused systems which require improved telecoms connectivity, open data and the required sensors on trains, stations, and the rail infrastructure.

This will provide new opportunities to integrate rail data into passenger-facing apps and connect data across systems. Such services will require GBR to support the government’s ambitions for 5G connectivity and the development of the railways’ digital infrastructure.

To provide seamless transfers between rail and other transport modes, GBR needs to work with other stakeholders to develop Mobility as a Service systems to encourage modal shift from car to public transport.

A whole-system future

The above gives an indication of the philosophy of IMechE’s response to the GBR transition team’s call for evidence, which will be more detailed than this short article.

The key message is the benefits of whole system thinking and how GBR offers potential for significant improvements in this respect. However, it will take some years before the GBR organisation is in place. Prior to then, any opportunities for whole systems thinking across the infrastructure/rolling stock divide need to be grasped.

This needs engineers on either side of this divide to consider whether anything could be done in relation to their activities that benefits the other side of this divide. Perhaps one example, mentioned elsewhere in this magazine, is the hot axle box detector (HABD) that was not configured to raise an alarm when it detected hot wheels, and so did not prevent the serious derailment at Llangennech.

It is clear that GBR will offer more opportunities to deliver railways that are better engineered for the customer. In the meantime, the requirement is for engineers to be more aware of the opportunities for whole system thinking.