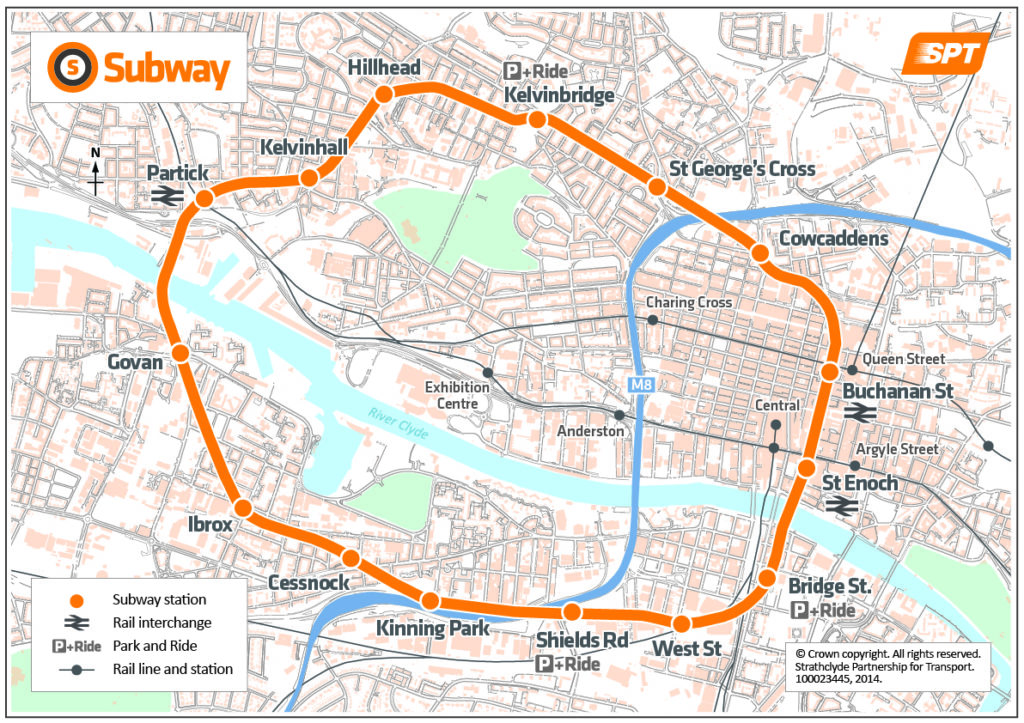

Glasgow’s Subway comprises a four-foot gauge double track in a circular 10.5km tunnel and is the world’s third-oldest underground railway (after London and Budapest). When it opened in 1896, there was no rail connection to the surface, so cars were lowered into the tunnels from the depot above.

Although trains were steam-powered, there was no smoke in the tunnels. Instead, a stationary steam engine moved a 10.5km long continuous cable in the track bed at a constant 19km/h. Trains were moved by a gripper that closed around the moving cable, as on San Francisco’s cable cars today. A legacy of this system is that each station is on a hump that helped accelerate trains down a steep gradient as the cable was gripped.

Although the Subway has not expanded in size since it opened 125 years ago, it has been the subject of two modernisation programmes. In the late 1930s the original cars were converted to electric traction. Between 1977 and 1980, the Subway was closed for a major enhancement programme that included station reconstruction, tunnel repairs, track bed and rail replacement. This provided the Subway with its first points as part of a triangular junction to provide a surface rail connection to the Govan depot. The 80-year-old wooden cars were replaced with a fleet of 32 new power cars. A further eight trailer cars were added in 1992 so that all trains could be three-car units.

The third modernisation

The 1970s refurbishment has served Glasgow well, with 13 million passenger journeys undertaken each year. However, after 40 years, it was time for another major enhancement programme. Otherwise, it was likely that increasing costs would force the Subway’s closure.

So, in 2011, Strathclyde Partnership for Transport (SPT) initiated a £288 million modernisation programme of which the Scottish Government contributed £246 million. The five main strands to this programme were smart ticketing, station refurbishment, infrastructure asset renewal, rolling stock and control system replacement, and organisational change.

Getting the workforce’s commitment to new working practices was an essential first step of the modernisation programme. SPT achieved this in 2012 with an agreement between UNITE and SPT for more flexible working and establishment reduction, with no compulsory redundancies.

Contactless Subway smartcards were introduced in 2013. Developed by Nevis Technologies – a joint venture between SPT and Ecebs – Subway cards comply with the UK ITSO standard and can have ScotRail and local bus tickets added to them. In 2015, Smartcard top up was extended to 45 retail outlets close to Subway stations using the Payzone system that also accepts payments for utility and credit card bills.

Station refurbishment

Refurbishing the Subway’s 15 stations accounts for around £50 million of the modernisation. This started in July 2011 with the second busiest station, Hillhead, and was completed in 2020. To avoid passenger disruption, 90% of the work was done in short night-time possessions.

As a result, all the Subway stations are now bright, modern stations with new SPT branding. These revitalised stations are expected to attract new patronage and also reduce operating costs by using lower whole-life-cost modern materials and energy efficient lighting. The system’s 28 escalators have been replaced by power-standby, energy-efficient versions.

The new stations incorporate DDA enhancements including hearing loops, tactile maps and paving, and colour contrast flooring. However, due to the constrained nature of the Subway’s small stations, it was only possible to fit lifts at Govan and St Enoch. There were three framework contractors for this work (Graham Construction, Sir Robert McAlpine and Clancy Docwra) and two framework designers: Austin Smith Lord and AHR.

Leaking tunnels

The modernisation programme includes a comprehensive programme of infrastructure works including tunnel repairs. The Subway’s two circular tunnels have a nominal diameter of 3.35 metres and are between three and 40 metres below ground level. They pass under the river Clyde twice and are mainly within the groundwater table. Construction methods varied according to the differing geology and used linings that were brick circular and horseshoe, concrete horseshoe, brick and concrete circular, and cast iron segmental.

Historic records show that the ground conditions encountered were hard going (rock) or particularly poor (loose sands/muds). The worst section between Buchanan Street and Kelvinbridge passed through former quarries. The differing forms of construction, in conjunction with changes in the surrounding soils, have led to varying degrees of deterioration over the last 120 years, resulting in significant water ingress with resultant maintenance problems, including rail corrosion.

Since 2015, Freyssinet has been undertaking tunnel lining upgrade work. In 2020 the company was awarded a further five-year contract for such work which includes annulus grouting, lining repairs, and resin injection leak-sealing. Pumps were also replaced at 21 pumping stations as part of a £2 million contract awarded to WGM Engineering in 2014.

Other tunnel work included the removal of 120km of redundant cable and the provision of a new chainage system to re-baseline tunnel survey datum. New datum plates with radio frequency identification were also installed.

The only closure

In contrast to the 1970s modernisation which saw the Subway closed for two years, the Subway has, with one exception, remained open during the modernisation programme. The exception was a one-month closure in 2016 to replace the track system in the depot access ramps and turnout chambers that were installed during the 1979 modernisation. This work included replacement of the concrete track bed and drainage, and renewal of the plain line rail, switches and crossings, and point motors. During this time replacement bus services were provided, mimicking the circular service on the surface streets above.

Around this time there was an accelerated re-railing programme which was completed 2017. This was needed because of the condition of existing rails and the requirement to start testing the new rolling stock at night.

Made-to-measure trains

Impressive though the station and infrastructure works are, the new trains will no doubt attract the greatest attention as they will be the first trains to operate in the UK with Unattended Train Operation (UTO).

Instead of procuring the trains by a prescriptive technical specification, prospective suppliers were given a concept of operation that covered general requirements such as the number of people to be carried and how SPT wished to operate the trains. A competitive dialogue then followed to develop the technical solution that offered best value.

In 2016, SPT announced that a consortium of Stadler Bussnang AG and Ansaldo STS (now Hitachi Rail STS) (ANSTA) had won a £200 million contract to supply its new trains, signalling and associated equipment.

Although there had been concerns that suppliers may not be interested in an order for a small number of four-foot gauge Subway trains, this proved not to be the case. Stadler, in particular, is known for its bespoke manufacturing operation with production lines that can easily be changed for small orders, such as 34 cars for the Berlin Underground and 10 Croydon trams.

Stadler is supplying 17 four-car articulated trainsets. Half of each set comprises of a power car with two bogies that supports one end of a trailer car that has one bogie at its other end. There are wide walk-through connections between the cars which have a standard floor height, made possible by smaller diameter wheels. Each train is 39.25 metres long, compared with 37.74 metres for the current three-car units. The trains have the same 58km/hr maximum speed as at present and have capacity for 310 passengers compared with the current 270.

The trains have secondary air suspension and cushioned, resilient wheels. This both improves ride quality and allows tyres to be replaced without removing the wheelset from the bogie. The wheelsets have radial steering to reduce flange wear. Wheel condition monitoring equipment will be installed at the depot to take daily wheel profile measurements, to predict when tyre turning is required.

The AC traction motors are water cooled with IGBT traction control that offers regenerative braking. Systems will be continuously monitored to detect potential defects. For example, increased effort and time to close a particular door indicates an emerging problem, allowing the problem to be investigated before the door fails. A system failure sends an alarm to control, complete with advice on the required action. With high levels of redundancy, it is unlikely that a fault would require a train to be taken out of service immediately.

Stadler unveiled the Subway’s new trains at Innotrans in 2018 and delivered the first train to Glasgow in 2019. There are now three pre-series trains in Glasgow. Due to their four-foot gauge, dynamic testing cannot be done before delivery so the trains are being tested on a 760-metre test track by the depot. This test track has been constructed by ANSTA having previously been part of the 1979 modernisation and follows the route of the closed Govan branch line.

ANSTA has built the construction depot and store adjacent to this track, which will be fitted with the new signalling system and have a platform with platform screen doors. This ANSTA-controlled facility is assembling and testing the new trains and is segregated from normal operations.

After a pause in production to assess modifications required following testing, the production run for the remaining 14 vehicles has now commenced. The three pre-series trains will be modified in Glasgow.

Once the new train fleet is operational, SPT will be responsible for its maintenance with support from ANSTA under a technical support and spares supply agreement.

UTO, PSD and CBTC

UTO requires a fully automatic signalling and control system. A key requirement is for controllers to monitor trains with on-board CCTV and to communicate with passengers if required. With no on-train staff, platform screen doors (PSD) will be fitted to control the platform train interface risk. These will be 1.7 metres high and provided by Gilgen Door systems, the company that installed them on Paris Metro line one when it was converted to UTO.

Signalling will be the Communications Based Train Control (CBTC) system that Hitachi has supplied to Copenhagen, Milan, and Stockholm. Car-borne Controllers (CC) calculate the train’s position using a tachometer which records distance travelled since the last track balise and transmits this to the Zone Controller (ZC). This determines movement authority limit for each train and advises each train’s CC of its limits. The CC then brakes as required and enforces speed restrictions. It also provides Automatic Train Operation (ATO) and controls the train’s doors and other systems.

The ZC also controls the Wayside Standard Platform (WSP). This operates and responds to infrastructure-based equipment such as platform doors, platform alarm buttons and point motors.

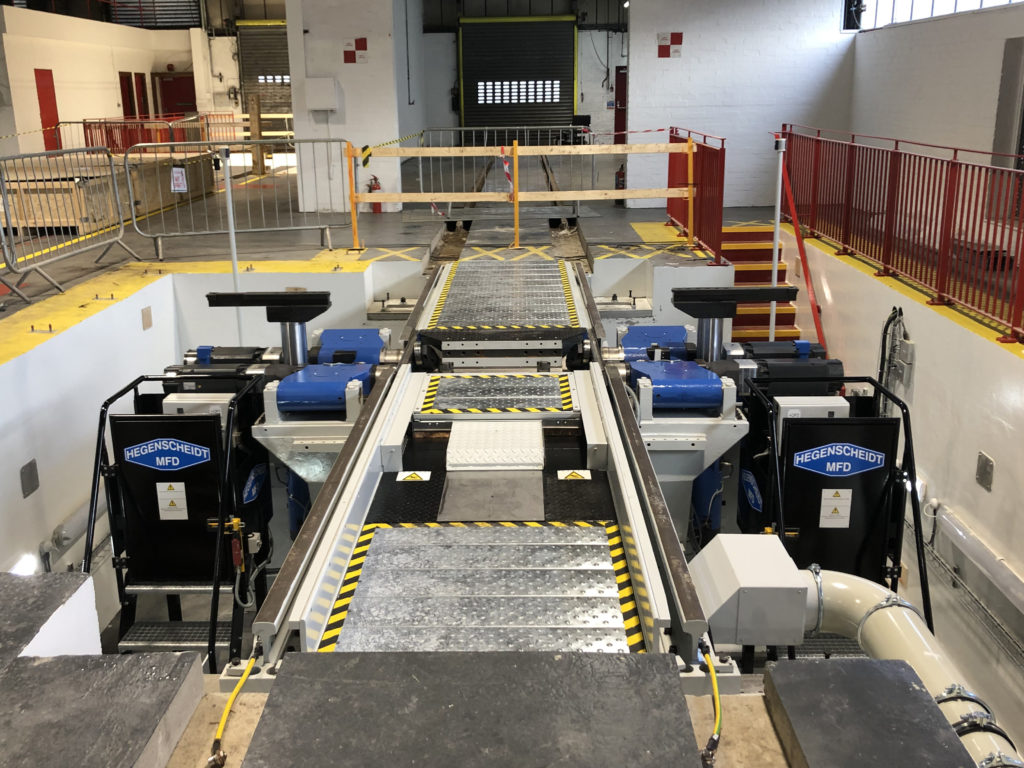

New hegenscheidt Wheel Lathe New Operations Control Centre Driver Simulator

Other aspects of the system are the Automatic Train Supervision (ATS) system and the iVENCS control system. The ATS regulates movement of trains in line with the performance and schedule requirements of the system. For example, when a train is due to enter service, the ATS instructs the WSP/ZC which then sets the points from the stabling sidings to the tunnel and the ZC instructs the CC to move the train at a safe speed. The iVENCS control software manages passenger-related infrastructure such as CCTV, information screens, and station assets.

Depot enhancements

A new Operational Control Centre (OCC) has been built at the depot to house the signalling and control system, train control, and driver simulators. This incorporates best security, safety and ergonomic practice. A new Hegenscheidt wheel lathe has been installed at the depot so wheelsets will no longer be sent away for tyre turning. A new, fully automatic, UTO-compatible wash plant will also be provided.

Although trains will enter the stabling sheds under UTO, they will be manually driven into the maintenance sheds. The trains will arrive under UTO at a platform from where they will be driven into the maintenance sheds using a flip-up control panel, provided at each end of the train.

Getting to UTO

The delivery and commissioning of these trains and their transition to UTO is a complex programme. The first step is testing the new trains in the Subway’s tunnels at night when there is no public service. It is hoped that this might start soon. The trains will then need to accumulate significant test mileage before they can enter service.

At this point they will be operating under the existing signalling system and will be manually driven from a temporary cab created by a partition wall. This will be removed after the introduction of UTO. After a period of mixed fleet running the existing fleet will be withdrawn. It will then be possible to commission the new CBTC signalling system and install the platform screen doors that are not compatible with the door spacing of the existing fleet. Once this is done, it will be possible to introduce UTO.

UTO offers many benefits including the flexibility to introduce additional trains for short periods to move exceptional crowds. If required, the normal four-minute headway can be reduced to as little as 90 seconds. This, no doubt, will be appreciated by the thousands of Rangers fans who use the Subway’s Ibrox station to get home from a match.

Introducing the first UTO service in the UK is a challenging project, not least in respect of the approval process for which SPT is in constant contact with the ORR. DfT is also being consulted about cyber-security. SPT also has close ties to all metro operators across the world through its membership of UITP and is constantly learning from other operators which have converted to UTO, in particular the Paris Metro.

Given the unknowns associated with installing and commissioning this complex system on the Subway’s 125-year-old infrastructure, the SPT has not committed to a date for UTO operation. However, the programme is taking longer than originally envisaged when it started in 2011. Reasons for this include the complexity of installing infrastructure in the old, constrained tunnels, and the Covid pandemic.

However, this delay has not inconvenienced passengers, who have experienced various improvements during the modernisation programme while the system has been kept open. The eventual introduction of UTO trains offers passengers further improvements and brings the SPT significant business benefits. This will also ensure that the diminutive new Subway trains will attract much attention and might perhaps encourage standard-gauge operators to follow the SPT’s trail-blazing approach to train operation.

Rail Engineer wishes the Subway well as it celebrates its 125th birthday on 14 December, and looks forward to seeing the completion of its modernisation programme in the not-too-distant future. As we go to press, we learn that one of the new Subway trains entered the tunnels for the first time for testing.