What happened

At approximately 18:43 hrs on 31 October 2021, on a day that had been exceptionally windy and immediately after a localised period of drizzle, South Western Railway (SWR) passenger train 1L53, the 17:20 hrs from London Waterloo to Honiton, passed a red signal and collided with the side of Great Western Railway (GWR) passenger train 1F30, the 17:08 hrs service from Portsmouth Harbour to Bristol Temple Meads.

At the point of collision, the SWR train was travelling at approximately 52mph and the GWR train at 20mph. The collision took place at Salisbury Tunnel Junction, which is on the immediate approach to Fisherton Tunnel, near Salisbury in Wiltshire. Scan the QR code for an animation showing the paths of the trains involved.

The collision caused the front two coaches of the SWR train and the rear two carriages of the GWR train to derail. Both continued into Fisherton Tunnel for some distance before coming to a stop. Thirteen passengers and the SWR train’s driver required in-hospital treatment as a result of the accident. There was also significant damage to the trains and railway infrastructure involved. A potentially far more serious collision between the SWR train and an earlier train which was travelling in the opposite direction and crossed over the path of the SWR train was avoided by less than a minute.

Low Adhesion

Rail Engineer has reported extensively about work to manage the effects of leaf fall on the railway. When leaves fall on the track, the movement of trains tends to roll them between the wheels and rails forming a black film that is very slippery when wet and insulates when dry. This means that wet contaminated rails exhibit poor adhesion (values can be as low as 0.02µ), leading to difficulty in applying power and much longer stopping distances.

Dry, contaminated rails are less slippery but can lead to wrong side track circuit failures (occupied blocks can appear to be unoccupied). Clearing the trees can eliminate the problem almost completely. Rail head treatment trains (RHTT) can be used to blast the leaf film with water jets at a pressure of 1000-1500 bar, sometimes with the use of an adhesion traction enhancing sand/gel treatment applied from the RHTT or trackside.

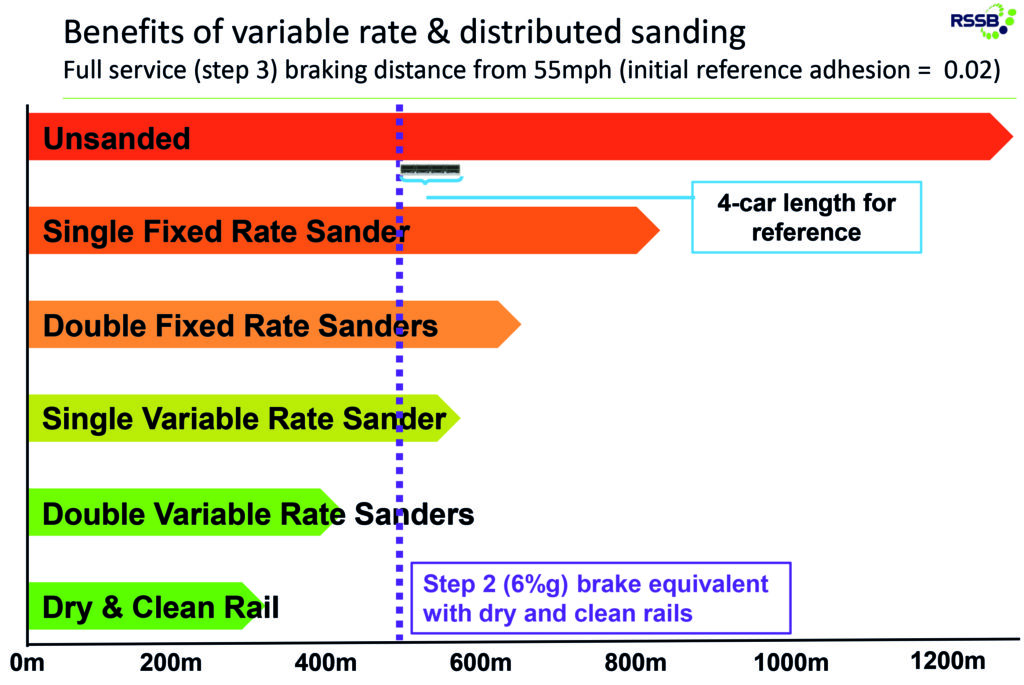

Mitigations include speed restrictions, signage to identify high risk areas, and instructing drivers to use defensive driving (brake earlier and more lightly). Train features such as better wheelslide protection and various forms of sanding can improve stopping distances.

Each site has its own individual features and the weather introduces additional variables, especially wind and rain. This makes day-to-day operational risk management a multi-dimensional task that requires specialist technical skills and the ability to coordinate with the many organisations/departments involved.

In February this year, Andrew Hall, chief inspector of the Rail Accident Investigation Branch (RAIB), gave a keynote address at Rail Media’s Rail Safety Summit with the title: ‘Rarely is Not Quite Never’. He could almost have been thinking of the collision at Salisbury Tunnel Junction, where, according to the RAIB’s interim statements, a significant factor was low adhesion caused by damp leaf film on the rails.

The railway community puts in a huge amount of effort each year to manage adhesion problems during the autumn leaf fall season, and although there are wrong side failures (SPADS, station overruns, etc), it is rare for there to be a collision.

Although the Salisbury collision was serious, it could have been a whole lot worse, as a third train cleared the junction just one minute before the two-train collision. This was described in the 113-page report published by RAIB in late October 2023, just before the second anniversary of the collision.

The final RAIB report discusses the many controls and mitigations the industry uses to manage the risk of a collision in low wheel/rail adhesion conditions and how almost all failed on 31 October 2021. RAIB concluded that the causes of the collision were:

A) Wheel/rail adhesion was very low in the area where the driver of the SWR train applied its brakes, because:

- There was leaf contamination on the railhead, resulting from the weather conditions on the day of the accident and since the last rail head treatment run.

- The impact of the leaf contamination had been made worse by a band of drizzle that occurred immediately before the SWR train passed.

- There was an increased density of vegetation in the area and,

- Network Rail’s Wessex route had not effectively mitigated the railhead contamination.

B) The driver did not apply the train’s brakes early enough when approaching the signal protecting the junction to avoid running on to it, given the low level of adhesion.

C) The braking systems on the SWR train were not capable of mitigating this very low adhesion.

This article summarises the key points and conclusions in RAIB’s roughly 36,000 word report. Anyone wanting more detail should read the full report.

The report discusses the actions of members of staff in Network Rail management in operations and maintenance, SWR management, and the driver of the SWR train. As is normal process, RAIB discusses each area in turn.

Vegetation

Before arriving at the conclusions in point A), RAIB discussed the actions of Network Rail (NR). It noted how vegetation on the route taken by the SWR train had significantly increased since the last days of steam and the early days of diesel operation (1967-73). It examined processes for identifying and assessing the risk posed by lineside trees and foliage, and processes for planning and carrying out clearance, before assessing whether and how well they had been complied with.

The investigation identified several issues with process between 2018 and 2021. It also found that that no action had been taken to manage the vegetation over the approaches to the accident site, yet the risk scores had not changed despite the vegetation continuing to grow. RAIB said this called into question the robustness of the process. Other issues such as the output of inspections not being entered into NR’s Ellipse asset management system were also identified.

It described how the organisational relationships between the various departments within Network Rail were supposed to work and the standards applicable to managing, preparing, and collaborating internally and with the train operator in planning and responding to autumn and low adhesion incidents. use QR code to see organisation charts.

RAIB identified issues with how this worked in practice and also with standards, processes, skills/competence, and people shortages.

For the managing lineside foliage process, RAIB said that the standards were complex and seemed aimed at both postponing work and being insufficiently precise which allowed inspection results to stay the same while the foliage becomes more overgrown.

It also identified some lack of competence and experience, difficulty in organising contractors to carry out work, and difficulty in getting access, compounded by the ban on red zone working.

The report recognised that it is not practical to eliminate leaf film on rails and described many of the techniques the industry has developed to clean the railhead, either with railhead treatment trains (RHTT) or lineside adhesion gel applicators. RHTTs were scheduled to run on this section twice a day during the week and once a day at weekends. Fewer runs at weekends were reported to be the result of weekend engineering work disrupting RHTT diagrams, but it was clear that the risk is just as acute at weekends as on weekdays. On the day of the collision, the RHTT had not run. RAIB explained that staff in the Wessex Integrated Control Centre (WICC) could call for additional runs in response to reports of low adhesion but hadn’t realised the area was at risk that day despite the windy weather.

WICC could also call on Mobile Operations Managers (MOM) to carry out inspections of the railhead in high-risk areas, and RAIB reported that such an inspection had been called for, but no MOMs were available. It added, however, that MOMs had reported that they were unable to work trackside without a line blockage and had been asked to assess rail head condition from overbridges and lineside fencing, an exercise MOMs thought was of very limited value.

South Western Railway

RAIB commented that the requirement to inform drivers about low adhesion and for drivers to feedback about low adhesion was not being consistently followed, illustrating this with a photograph of a low adhesion notice in comparatively small type on a noticeboard behind glass and with comments from other drivers that they did not have enough time to study all the notices.

The train in question was a three-car class 159, although it should have been a six-car/two-unit train. Longer trains generally deliver better braking performance on poor adhesion than short ones.

The driver

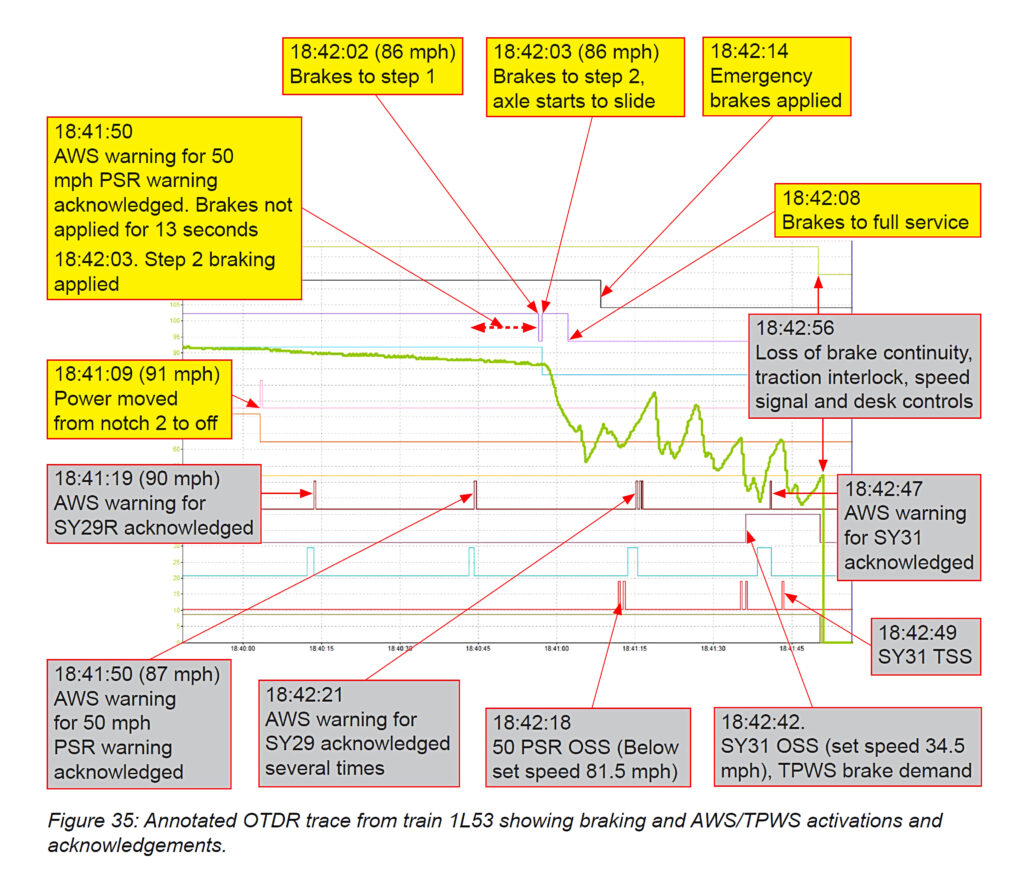

RAIB’s conclusion that the driver braked too late was based on analysis of the SWR train’s On-Train Data Recorder (ODTR) and interviews with the incident train’s driver and other drivers who operate class 159 units on this line.

The analysis, from this and other trains, showed that the driver, having seen the double yellow at signal SY29R, braked much later than he usually did and later than other train drivers on that route. During the high winds earlier that day, a tree had fallen on the line to the southwest of Broken Cross bridge which the driver observed on the way up to Waterloo (during daylight).

The driver explained that when he saw the double yellow signal, he thought there would be low adhesion at the site of the fallen tree, so he decided to look for the tree and brake immediately after it. But it was dark, and he missed the tree and only initiated braking in step 1 over a mile after SY29R. He rapidly increased the brake rate to step 3, the maximum rate, before selecting emergency brake shortly after. The train’s wheel slide protection and sanding were unable to provide the deceleration rate required in the low adhesion conditions caused by the leaf film and the drizzle that passed over the area shortly before the SWR train approached. In simple terms, when all the other risk controls had failed, the driver – the last line of defence – made a mistake, leading to the collision.

Signal spacing

But it wasn’t quite as simple as that. RAIB found that the 3.1 km between signals SY29R and SY31on the approach to Salisbury Tunnel Junction provided an excessive braking distance for passenger trains, meaning that drivers must delay full braking until after they have passed the double yellow aspect signal (SY29R), otherwise they could stop short of the red signal (ST31) and/or incur time delays on their journey.

The driver involved in the collision said he would normally have started braking at Broken Cross bridge. However, on 21 October 2021, the driver decided to brake at the fallen tree, 250 metres beyond the bridge, but, having failed to see the tree, only started braking approximately 1,000 metres beyond the bridge. The current applicable standards are RIS-0703-CCS and NR/L2/SIG/30009/D220 which states:

“If the distance is significantly greater than the minimum then this may lead to drivers continuing at the permissible speed and trying to judge when to brake with the risk of SPAD, or braking early and coasting leading to an increase in journey time or loss of capacity.”

Although these standards recognise the risk, the signalling approaching Salisbury Tunnel Junction pre-dates those standards, and there was no requirement for retrospective action.

Actions since the collision

In the two years between the collision and the publication of the RAIB report, lessons have been learned and actions agreed. RAIB reported that a joint internal industry investigation was carried out which recommended actions for Network Rail and SWR. These actions broadly align with RAIB’s own, described below. Other industry bodies including GWR, RSSB, the Seasonal Challenge Steering Group, and the Rail Delivery Group also carried out a number of actions. An item not seen elsewhere in the report is the plan to fit Single Variable Rate Sanders to the SWR class 159 fleet. This modification can reduce the braking distance of trains in low adhesion conditions.

In December 2021, ORR issued an Improvement Notice to Network Rail requiring it to carry out a number of improvements that broadly correspond to RAIB’s recommendations. ORR had reported that Network Rail had complied with the notice and “taken action to manage the risk from adverse railhead conditions caused by leaf fall”. The actions taken include:

- Engaging with stakeholders and reviewing data to update risk assessments and identify new and existing sites at high risk of low adhesion.

- Targeted vegetation removal work at the highest risk sites.

- Implementing changes to the railhead treatment programme including revised treatment circuits and speed, and trialling new treatment products.

- Strengthening mitigation processes when railhead treatment is missed.

- Briefing autumn working arrangements to relevant people. The arrangements include inspecting high-risk sites and auditing railhead treatment effectiveness.

- Strengthening assurance arrangements for autumn management.

- Planning future engineering works around the railhead treatment circuits and trialling new technology to identify railhead contamination.

RAIB recommendations

RAIB made 10 recommendations, the text of which is too long to publish here. Instead, we have quoted the intent of each recommendation and the organisation(s) to which each was addressed.

Recommendation 10 needs explanation. This article has not discussed the structural performance of the trains during the collision, nor the evacuation, but recommendation 10 relates to the difficulty some passengers had in opening bi-parting interior power doors on one of the class 159 coaches.

1: Network Rail: To have autumn working arrangements that more effectively manage low adhesion risk, as a result of leaf fall.

2. Network Rail: To have seasons delivery specialists that are more effective in managing Network Rail’s seasonal risk.

3. Network Rail: That off track staff are sufficiently competent and confident to undertake the tasks assigned to them by Network Rail standards.

4. Network Rail: To be able to make more effective decisions regarding the management of emerging and potential low wheel/rail adhesion conditions.

5. Network Rail: To improve wheel/rail adhesion conditions through the application of improved understanding of the effectiveness of railhead treatment regimes.

6. Network Rail: To enable the effective assessment by Network Rail of the risk of overrun at signals which have HRLA sites on their approach. Network Rail

7. Network Rail: To reduce the risk of overrunning signals at danger where there is a line speed change on the approach after the preliminary caution signal.

8. South Western Railway: Drivers to be able to identify areas of low adhesion and report them, if appropriate.

9. Rail Delivery Group: The industry to realise the potential benefits of future technologies to enable trains to better cope with low wheel/rail adhesion when braking.

10. Porterbrook, Angel Trains, and Eversholt Rail: To minimise the risk that passengers are unable to evacuate from class 158 and 159 carriages.

Conclusion

RAIB’s in-depth report identified the many risk controls that contribute to the safety of the railway in autumn, low adhesion conditions, and, in most cases, found fault with the application of these controls. It is to be hoped that this accident has been a wake-up call for increased vigilance, competence, and attention to detail. One omission appears to be any recommendation aimed at significantly reducing the quantity of trees and other foliage around the railway to largely eliminate the risk of low adhesion at source. Comparing images from 50 years ago with today it seems that, in many areas, open countryside has been replaced by tunnels of trees. Perhaps it concluded that the task of so doing is too great?