Spanish company Construcciones y Auxiliar de Ferrocarriles (CAF) has opened a factory at the Celtic Business Park in Newport, Wales. Previously, your writer has had the privilege of touring CAF’s facilities in Zaragoza and Besain, and on a recent study tour there was an opportunity to visit the Newport facility.

When CAF was looking for a possible site to assemble trains in the UK, it explored over 100 locations before settling on a part of the former steelworks in Llanwern, South Wales. It is located alongside sidings which follow the main line between Newport and Bristol Parkway, and the site has three main, but integrated buildings: a three-road assembly plant; a five-road test shed; and a stores building. The east end of the site has a traverser to allow vehicles to be moved from road to road, and a water test facility. The plant will shortly be connected to the siding, but all completed vehicles to date have been delivered by road.

The project cost approximately £30 million and the footprint of the buildings covers an area of 1,400 m2, with capacity to extend onsite as CAF owns 46,000 m2. By 2020, there were over 200 employees on site and CAF expects that to complete the current order book, up to 300 staff will be necessary. Construction of the factory started in 2017, with production of rolling stock starting in 2018. The site was officially opened by the Prince of Wales in February 2020.

The tour

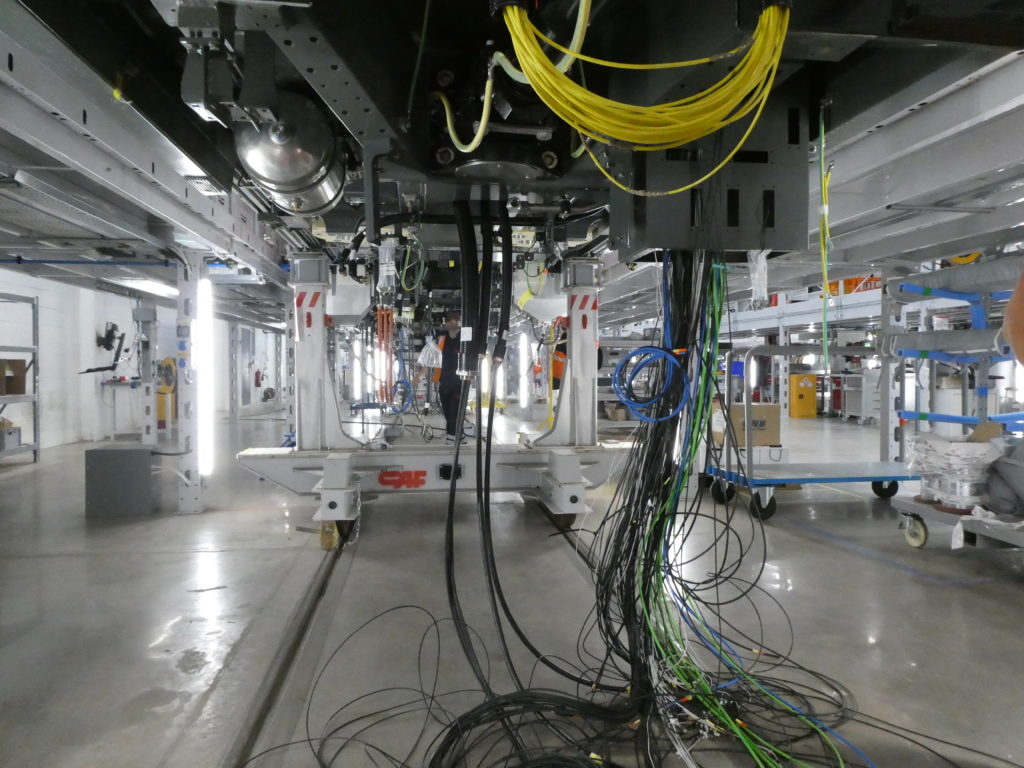

On arrival at the site, a number of painted car body shells were observed at the west end of the factory awaiting their turn for assembly. The tour commenced in the stores, where the sheer range of brought-in items was observed. Sub assembly starts here, and our group saw a pneumatic frame being assembled and the area where the hot water saloon heating modules are assembled and leak tested. Then, up to a mezzanine where the electrical wiring looms were assembled into bundles ready to be fed into the vehicles.

An overriding reaction is that “surely, trains don’t need that many wires?”, but remember that they require electrical sockets to every seat, air conditioning, electrically operated doors, passenger information systems, lighting, seat reservations, WiFi, and many more systems that demand electricity. Trains have moved on from the simple 42-way cable down the trains.

When the painted shells enter the first of five zones in the workshop, the production team start with marking out for the floor fittings. Here, they use templates reminiscent of a giant plywood jigsaw puzzle, where each piece has cut-outs forming masks for the painted location marks to position the internal floor supports − simple, accurate and reproducible.

The supports were fitted next, followed by the carpeted floor. This stage included the start of fitting heat/sound insulation and fitting window frames, the latter involving generous use of Sika adhesive/filler products; cue for much humour about whether manufacturers would cope without Sika products. On the underframe some of the basic mounts for equipment were fitted – many threaded fasteners captive in the C-section solebar tracks.

The second zone involved fitting the electrical harnesses, making sure that all the wires were fed though to the correct parts of the vehicle, and installation of equipotential bonding cables (making sure all parts of the vehicle were earthed). Although some connectors were pre-fitted, most were fitted after the looms had been installed on the vehicle. The door mechanisms and doors were fitted at this stage, and carefully aligned so that they opened, closed, and plugged smoothly. The CAF guides reassured the group that, on test, little re-adjustment is necessary even though significant extra mass is added to the vehicle at later production stages, potentially, altering its shape slightly. Also fitted was the window glass, front end obstacle deflector, autocouplers and toilets.

The group was able to examine the underframes at this stage. There was an opportunity to see the installation of the diesel engine heat detection and fire extinguisher system, and the substantial C-section tracks in the aluminium extrusions which are used to support underframe mounted equipment.

Zone three involved fitting the saloon and cab HVAC systems, internal ducting, internal final finishes, and the partition wall between the cab and the saloon. In zone four, the vehicle gained its diesel engine/gearbox raft whilst, inside, the internal cladding, final surfaces, draft screens, door pillars, and final trims were completed. Windows were also fitted in the driver’s cab.

Completion and testing

Zone five was where the interior was completed with the installation of seats and tables, passenger information systems, cab and non-cab end gangways as appropriate, and headlights. Finally, the vehicle was united with its bogies and all connections − electrical, pneumatic, and cardan shaft – were made.

The completed vehicle was towed out of the shed using a small rail-mounted, battery-powered shunting vehicle and onto the traverser where it was moved to the water test building to search for leaks. From there, it was on to one of the test roads. Here, computer aided equipment was used to test the integrity of the wiring looms, including insulation integrity, before coupling into a unit for functional tests to prove all the equipment. The test shop included diesel engine exhaust extraction. After cleaning, the units are uncoupled and prepared for delivery to a site near the customer for dynamic commissioning.

Current production

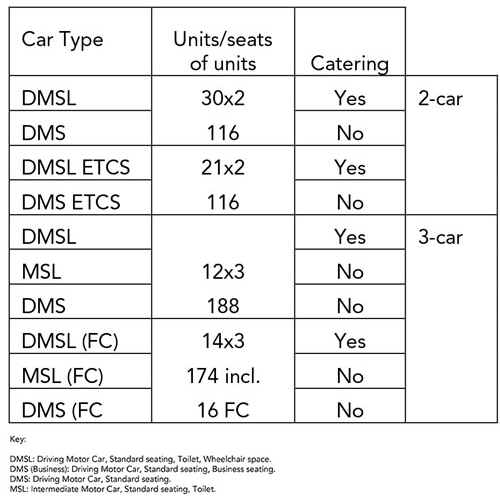

At the time of the visit in early May 2022, production of 180 class 197 diesel multiple unit vehicles for Transport for Wales (TfW) was in full swing. These might possibly be the last diesel-only passenger trains built for UK rail, given the decarbonisation imperative. They are based on the CAF Civity platform which, in DMU form, has also included Northern’s class 195 (149 cars), and West Midland Railways’ class 196 (80 cars). Classes 196 and 197 feature unit end gangways. There will be four configurations of class 197, as shown in Table 1.

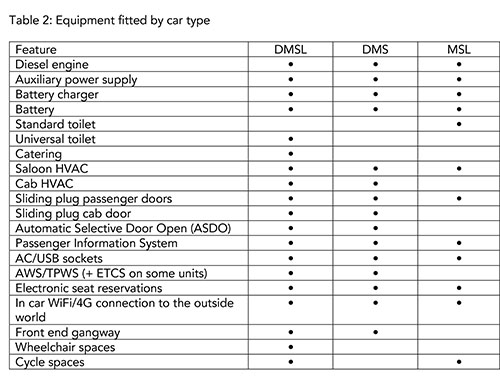

All cars have a gangway at each end and the gangway at cab ends permits circulation between units when running in multiple. Each car has a 375kW MTU power-pack driving both axles of one bogie. The other bogie is unpowered. Bogies are inside frame type with coil spring primary and air bag secondary suspension, wheel cheek disc brakes, yaw dampers and anti-roll bars. The main equipment on each car is shown in Table 2.

Transport for Wales has specified that catering trolley service and a catering area is provided on each DMSL car containing a cold cabinet, a freshwater tank, water heater, dry food store (e.g., crisps and biscuits), and trolley storage.

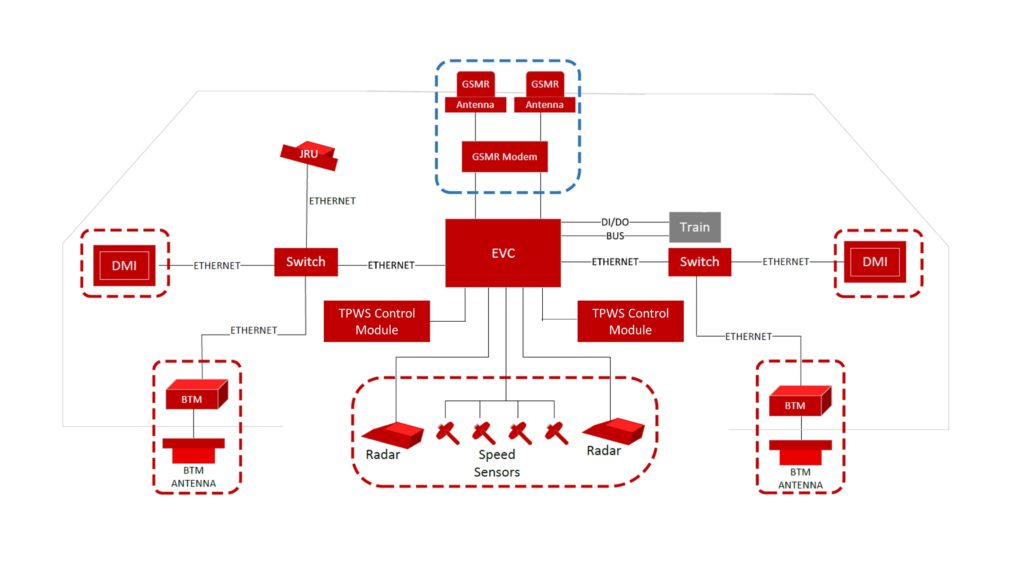

The introduction of class 197 units onto the Cambrian line means that they need to be equipped with ETCS. This ETCS will be the CAF AURIGA on board system compliant with the latest ETCS specification. For this to be used, the infrastructure on the Cambrian line needed to be upgraded to baseline 2.3.0d which was commissioned on 15 May 2022 at a cost of £3 million.

Fitting ETCS to the train is complex and the basic architecture is shown in the adjacent diagram showing the various items of equipment required in each cab connected via ethernet:

- A European Vital Computer including a Juridical Recording Unit

- Human Machine Interface (driver’s touch screen panel including speedometer)

- Balise readers

- TPWS sub system

- Tachometers

- Doppler radar speed measurement

- GSM-R data radio

Unit end gangways

Finally, there are other issues affecting the interface between the class 197 units and the infrastructure caused by the desire for cab end gangways. TfW is familiar with cab end gangways (class 150, 153, 158), but there are new challenges for the class 197, in common with all other suppliers’ modern unit end gangway designs. The current crashworthiness standard effectively requires the driver to be further away from the windscreen and the gangway is somewhat longer than the older trains. Both factors result in the driver’s forward view being narrower.

This means that trains must stop further away from signals, and in critical locations modifications to the infrastructure might be necessary. For example, at short platforms where the signal is at the platform end, the back of the train might not be completely in the platform requiring ASDO, the platform might need to be lengthened or the signal might have to be moved.

Conclusion

The class 197 trains made in Wales are a significant part of TfW’s ambitious plan to deliver integrated transport for the country as described elsewhere in this issue. As of early May 2022, 30 units had been completed, with eight units undergoing fault-free running and crew training, and two units having the new yaw damper brackets validated (Issue 195, March/April 2022). Rail Engineer is sure that these trains will be welcomed by customers when they start entering service from Chester, expected in Autumn 2022.

With thanks to the management of CAF Newport for hosting the visit during an organised Institution of Mechanical Engineers’ tour and to CAF’s Graham Taylor for his assistance with this article. Photos courtesy of CAF/Graham Taylor.