Carstairs is in the upper Clyde valley, 200 metres above sea level, and on the West Coast Main Line (WCML) 46km from Glasgow. Its junction with the 44km line to Edinburgh is to the east of its station. In addition to these main lines, it served various long-closed branch lines. It is now served by a two-hourly service between Glasgow and Edinburgh, though it has over 200 passenger and freight services pass through the junction on an average midweek day.

In its day, Carstairs was a busy railway centre with a grand station, having a 91-metre-long building comprising of ladies’ and gentlemen’s waiting rooms, a telegraph office, a tearoom, and offices for the station staff. Its curved 300-metre island platform was originally between the Up and Down main lines with Up and Down loop lines for express trains to pass stopping trains. Adjacent to the station were motive power and train crew depots and, eventually, an electrification depot.

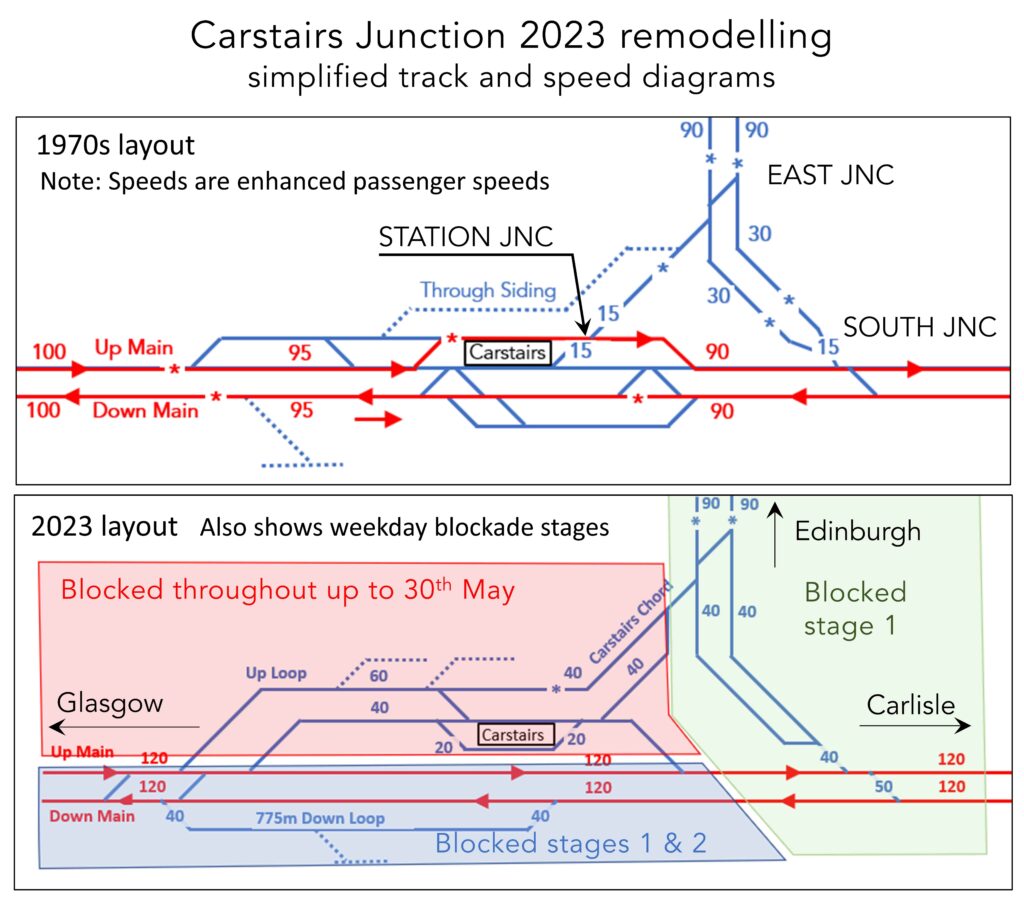

1970s modernisation

The WCML was fully electrified in the early 1970s, accompanied by re-signalling and an extensive remodelling of the track layout. To provide 90mph running, the Up line through the station was a heavily canted curve whilst the previous Down loop became the Down main line away from the station.

The connection from Edinburgh to the Down platform has a reverse cant as its two switches cross the superelevated Up main line with a 15mph speed limit. A further complication of this high-speed curved line was its deep ballasting which required the Up platform to be raised. This necessitated steps and continuous railings between the different levels of the Up and Down platforms due to the presence of the original station buildings.

When the Motherwell Signalling Centre opened in 1972, it controlled the WCML as far south as Gretna. When this closed in 2019, its area of control was transferred to the West of Scotland signalling centre. In the late 1990s, the relay room at Carstairs suffered from wiring degradation which had the potential risk of a wrong side failure. Hence, it had to be replaced as a matter of urgency. This was done using a novel interfaced SSI solution which left all the 1970s outside signal cabling and equipment in place.

The motive power depot closed in 1966 to become a stabling point. Locomotives were needed here until the early 1990s as many trains to and from Glasgow and Edinburgh were split or joined at Carstairs. Now the only such train is the Lowland Sleeper that has Edinburgh and Glasgow portions. When the original station buildings were demolished in 1999, they were replaced with a small waiting room and ticket office. With the removal of the old buildings, it was possible to level the platform.

The new layout

The 50-year-old layout at Carstairs Junction was designed for the train service of its time. Daytime trains no longer split and join at the junction and there has been an increase in through passenger trains on all three sides of the junction, as well as an increase in WCML freight trains. The old layout restricted speeds, caused many maintenance issues, and had switches and crossings that were not required with others on canted track that are difficult to maintain. Moreover, the track switches and the signalling system was at the end of its serviceable life.

To address these issues the 2km-long layout is being remodelled to:

- Replace the through siding north of the station with the new Carstairs Chord line which enables express trains to bypass the station.

- Move the Up main line to the south of the station and increase its line speed from 90 to120mph.

- Increase the speed of the Down line from 95 to120mph.

- Provide Up and Down platform lines that are generally only to be used by trains stopping at the station.

- Remodel Carstairs East Junction and Carstairs Station Junction to increase line speed from 15mph to 40mph for trains from both Glasgow and the south to Edinburgh.

- Extend the 594 metre Down passenger loop to hold 775 metre freight train.

The track and civils work is being delivered by the Rail Systems Alliance Scotland which consists of Network Rail with contractors Babcock and Arcadis who, in 2019, won a 10-year track and rail system framework contract to deliver track renewals and enhancements in Scotland. At Carstairs they are being supported by sub-contractors Story and QTS and are also working with Siemens who, in 2021, won the contract for the signalling enhancements at Carstairs. The OLE work is being done by SPL Powerlines as part of their electrification framework contract.

Digital design

The complex multi-disciplinary design of the Carstairs upgrade was undertaken by Arcadis using a digital twin. This was described in a recent webinar by Chris Conroy and Prasad MN who are respectively digital and information management lead senior BIM (Building Information Management) coordinator for Arcadis Rail in Scotland.

Chris noted that although Network Rail has specified the use of Projectwise for digital collaboration, Arcadis decided to use a suite of tools to produce a digital twin to co-ordinate the design which involved 10 different disciplines. He advised that some members of the team were initially quite sceptical about this as, for them, it was a new method of working. He also understood that the client also had no previous experience of digital twins.

Yet the value of this approach was apparent well ahead of construction when it became clear to all concerned that using of a digital model speeded up decision making and facilitated savings through design rationalisation. It also enabled project design to continue at pace during Covid when it could have been delayed by lockdowns.

The digital twin was also used to aid signal sighting, provided a virtual aid to reduce the time to train drivers on the new layout, and produced site safety briefing videos and project visualisations for external communications. All this generated positive feedback about this digital way of working which led to Arcadis being invited to provide digital design support for another major Scottish project. Chris felt that the Carstairs project’s use of BIM had made real savings, reduced project risk and increased the understanding of BIM processes within Scottish supply chain.

Prasad described how the following Bentley Systems tools were used: Projectwise for document sharing; Assetwise for asset information; AECOsim for discipline drawings; MicroStation Connect and Rail Track for 3D track design; LumenRT for signal sighting images; Open Road to create a ground surface modal; iTwin for coordination and review; Navigator for clash detection; and Context Capture for the reality mesh.

He explained how different discipline models were reviewed for conflicts at fortnightly co-ordination meetings when clashes were assigned to the appropriate responsible party. In this way, over 15,000 such clashes had been identified and dealt with at an early design stage. He considered that this was just one of the many benefits which included a significant reduction in site visits and technical queries. BIM also made it much easier to collaborate with the eight design houses involved in the Carstairs project who were situated in seven cities across the world in different time zones. This included Arcadis personnel in India. He noted that the model required 2 gigabytes of data, but considered this was manageable with the available tools.

Parsad acknowledged that, although digital twins are not a new technique, the Carstairs project had given him the opportunity to use a wide variety of techniques in different circumstances to ensure that the right tool was used for the right job at the right time.

Preparatory work

This digital approach was also used to select the best blockade option and determine the preparatory work that needed to be done beforehand. Work on site started in January 2021 with the establishment of site compounds, initial survey work, and the installation of new OLE masts.

Track renewal work and further OLE work was undertaken during weekend possessions in summer 2022. This included the installation of OLE portal frames over all tracks both due to the revised layout and because such portals can be installed within the short possession times.

The value of work done to date by October 2022 was £100 million. This included installation of 121 new OLE structures, together with 3km of track renewals and 1.5km of drainage. Work was also done during extended possessions around Christmas and New Year.

With the substantial completion of 55,000 tonnes of earthworks and 495 metres of retaining walls or regrading, the stage was set for the start of the blockade works which is in three stages:

- From 4 to 19 March – All lines blocked

- 20 March to 21 April – Route open between Edinburgh and Carlisle on weekdays with all lines blocked during 54-hour weekend possessions.

- 24 April to 4 June – Route open between Glasgow / Edinburgh and Carlisle on weekdays with all lines blocked during weekend / bank holiday possessions.

- Carstairs station remains closed between 4 March and 30 May.

During stage 1 and the weekend closures, freight is diverted via the Glasgow and South Western line via Dumfries whilst passengers from Glasgow and Edinburgh are bussed to Carlisle. During stage 2, weekday services between Glasgow and Carlisle trains are diverted to use the Edinburgh to Carstairs line by reversing at Midcalder Junction. On weekdays during stage 3, a near normal train service operates.

Blockade work

By the end of the first blockade between 4 and 20 March, the South Junction onto the WCML was installed and the associated OLE and signalling work undertaken. This required the installation of four S&C units with associated OLE and signalling work, with 54 hours of wheels-free testing required to commission the junction.

Elsewhere, three lines were plain lined and redundant S&C was recovered. OLE work included the removal of 6 portals, 27 masts, 5.8km of wiring, and running out of a kilometre of wiring with new neutral sections and switch feeds. During this first stage, a data change for the junction remodelling was made at the West of Scotland Signal Centre, two signalling gantries were installed, and two others were removed.

During the second stage the WCML Up and Down lines and the extended Down Passenger Loop (which is the 775-metre freight loop) were laid. This requires the installation of eight S&C units and associated signalling and S&C work. The installation of 6.8km of OLE wire also took place during this stage.

The final stage of the blockade will complete the Up and Down platform lines, the Up Sidings and Up Passenger Loop, as well as the new Carstairs Chord line to enable the junction to be fully opened. This will require the installation of six S&C units with much tamping to be done throughout the junction. The OLE work in this stage includes 2.3km of OLE wire runs with the replacement of neutral sections.

The three stages of the blockade will require 107 engineering trains totalling 1,768 wagons to deliver 43,635 tonnes of ballast and 11,559 tonnes of sand, as well as to remove 55,658 tonnes of spoil. This is required for 11.2km of new track, 30 new point ends, and the replacement or recovery of 41 point ends.

Civil engineering work includes over 55,000 tonnes of earthworks, 495 metres of retaining walls and slope regrading, and 4.3km of drainage. At Carstairs station, a small amount will be shaved off the east end of the Down platform to provide a higher speed curve on the approach to the platform. In addition, copes on the Up platform will be adjusted as the Up platform line will no longer be canted for 90mph running.

The OLE work included the installation of 74 new structures, 191 new OLE piles for 27.5km of new OLE wiring with 125 OLE foundations removed.

The signalling work included 36 new signals, 30 signal refurbishment, two new signalling gantries with two old gantries removed, 5.3km of troughing with 40km of cable route renewals and refurbishment. The signals are controlled by Siemens Trackguard WTS digital signalling technology which uses an IP-based network to connect objects to the interlockings and control centres. This was its first use in Scotland. In addition, 87 functional supply points are being commissioned during the weekend possessions. At the end of the blockage, a 69-hour signalling commissioning is required to open the junction to traffic.

During the blockade, the opportunity was taken to take advantage of the reduced train service to do other work. As well as small-scale routine work, this includes a 10-week closure of the 279-metre-platform one Glasgow Central for track and platform work and the installation of a new bridge at Ravenscraig. This 6,000-tonne structure is being driven into position using self-propelled modular transporters (SPMT) in what is believed to be the biggest move of its kind in Europe.

Looking to the future

The statistics show the scale of the Carstairs remodelling project and explain its £164 million price tag. They also indicate the challenges associated with the work. With a workforce of around 300 people signing into the site each day, co-ordinating the work of different disciplines within a constrained area cannot have been easy.

This work was long overdue as it is 50 years since the layout at Carstairs was last remodelled and re-signalled. In the early 1970s, Carstairs saw seven daytime trains per day between London and Glasgow with a best time of exactly five hours. Now there are 19 such trains with a best time of four hours and 30 minutes.

The junction also presented significant maintenance difficulties as indicated by a 50mph temporary speed restriction at Carstairs which thwarted a record-breaking attempt to make the fastest London to Glasgow journey in June 2021 when a Pendolino unit clocked at 3 hours, 53 minutes, and one second for this run. This was just 21 seconds slower than the record set by British Rail’s Advanced Passenger Train in 1984.

The remodelling will resolve track maintenance issues of poor joints with a track geometry causing high rail wear, as well as technical non-compliances of S&C on curves and tight toe-to-toe distances between S&C units. As well as easing this maintenance burden, improved switching arrangements will provide easier isolations and reduce service impact during perturbed working. These and the benefits of being able to accommodate 775-metre freight trains, a bypass line and improved junction speeds to improve Edinburgh to Glasgow and Carlisle journey times, a more flexible layout, and 120mph running on main lines through Carstairs, give the junction a layout fit for its current train service.

Although it is 30 years since daytime locomotive-hauled passenger trains were joined and split at Carstairs, the layout has still to offer this functionality as the Edinburgh and Glasgow portions of the Lowland Sleeper train are combined here. HS2 services to Scotland will re-introduce the practice of London to Scotland trains having separate Edinburgh and Glasgow portions when they start running in about 10 years’ time. The plan is for these trains, comprising of 2 x 200-metre units, to split at Carlisle, after which the Glasgow portion will speed past Carstairs station at 120mph.

Image credit: Network Rail