Of HS2’s 208 route km, 52.2km is in tunnels. There will be 44.3km of twin bored tunnels comprising of Euston (7.3km); Northolt (13.6km); Chiltern (16.0km) Long Itchington Wood (1.6km); and Bromford (5.8km), as well as six cut and cover ‘green’ tunnels totalling 8km. In addition, an 850-metre logistics tunnel in London has been built to deliver materials and remove spoil between Old Oak Common and HS2’s London logistics hub.

This is a total of 104km of tunnelling which is being done on a scale never been seen in the UK. This explains why HS2 is Britain’s largest infrastructure project.

Bored tunnels

Ten new tunnel boring machines (TBM) have been procured from Herrenknecht to dig HS2’s 10 tunnel bores. These machines are typically 170 metres long, have a cutting head between 8.6 and 10.3 metres diameter and weigh 2,000 tonnes. Different types of TBM employ different methods of supporting the tunnel face during excavation depending on the ground conditions. With significant variation in ground conditions along the route, each one is designed for the specific conditions of its bore. TBMs are not generally redeployed for new tunnelling projects.

TBMs typically advance 15 metres per day. Their main components are a rotating cutterhead, spoil disposal system of either slurry pipes or a conveyor, and a tunnel segment erection system. All have shields to protect the machine until segments are installed. They also require a high voltage supply of typically 10MW. Multi-purpose vehicles (MPVs) run through the excavated tunnel to supply the TBM with concrete segments. The TBMs place seven 35cm-thick tunnel segments to form a 1.9-metre-long tunnel ring immediately behind the excavation. Each segment weighs 8.5 tonnes and has grout injected between it and the tunnel wall. Behind the TBM is a bridge under which a concrete invert is poured to provide a level surface for the MPVs.

The TBMs operate continuously and require a crew of around 17 people on each shift to operate them. They have a control room, welfare facilities, and a rescue chamber. TBM personnel took refuge in such a chamber in May 2022 while they waited for smoke to clear after an MPV caught fire in the partly excavated Chiltern bore. The control room monitors the pressure at the cutterhead and the amount of spoil removed compared with the volume excavated.

Inside HS2’s longest tunnel (youtube.com)

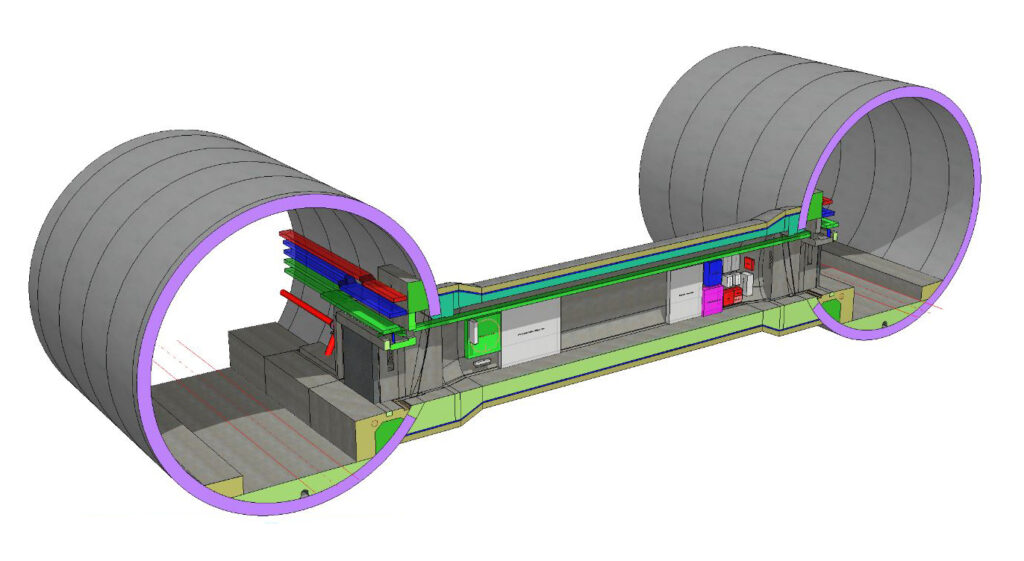

The rings along the alignment are uniform, expect where there is a cross passage between the tunnel bores. Here, strengthened ring segments are needed to allow other segments to be removed for the cross passage. These passages provide an escape route for passengers in an emergency and also house mechanical and electrical equipment.

There are cross passages between the two tunnel bores, 15 to 20 metres long, and every 500 metres. These are dug by a remote-controlled excavator and immediately reinforced by a steel-fibre reinforced sprayed concrete primary lining, after which a sheet membrane waterproofing system and a secondary cast in-situ concrete lining is provided.

The bored HS2 tunnels have ventilation shafts about every 3km. These regulate the tunnel air temperature, extract smoke in the event of a fire, and give emergency services access to the tunnel. A headhouse at the top of each shaft contains ventilation and fire control systems.

HS2 considers that, with the use of TBMs, there should be very little ground settlement from tunnelling operations. Nevertheless, this is an understandable concern for those who may be affected. HS2 is providing all those with properties within 30 metres of its tunnels or other excavations with a settlement deed which records the protection that HS2 provides to the property in a legal document.

Euston tunnels

Following the government’s Network North announcement in October, it is considering alternative funding arrangements to construct the 7.3km twin bore tunnels between Old Oak Common (OOC) and Euston, which have 14 cross passages and two ventilation shafts.

Nevertheless, the two TBMs required, costing tens of millions of pounds, have already been procured. These are earth pressure balance (EPB) TBMs with a cutting head of 8.5 metres diameter. EPB TBMs operate in soft ground conditions by mixing the excavated material into a paste which is injected into the evacuation chamber behind the cutters so that the chamber pressure balances that of the surrounding soil and groundwater.

This year, these machines will be placed at the end of the OOC station box ready to start excavating the 7.3km tunnel to Euston. HS2 anticipates that this tunnelling will start in 2026. The final fitting out of OOC station cannot be completed until the Euston tunnel TBMs have tunnelled out of the OOC box. Furthermore, concrete segments are supplied to the TBMs through the OCC box which also receives spoil from the TBMs.

This is possible due to the construction of the Atlas Road logistics tunnel which is another significant cost already incurred to support the Euston tunnelling. This is a 6.2-metre-diameter, 853-metre-long tunnel, from the OOC station box to the HS2 rail logistics hub at Willesden.

The Atlas Road tunnel TBM was one that had been refurbished by Herrenknecht after it had bored two Crossrail tunnels. It was named Lydia, after local school teacher Lydia Gandaa who launched it from HS2’s Atlas Road site in April 2023. It completed its bore by breaking into the OOC box in January.

This tunnel services both the Northolt East and Euston tunnels. It will have a conveyor to take the excavated London clay to HS2’s logistics hub when it will be taken by rail for reuse at sites in Kent, Rugby, and Cambridge. Assuming the Euston tunnels are built, over 83,000 tunnel segments manufactured at SRABAG’s Hartlepool plant will be delivered by train to the logistics hub and then through the logistic tunnel to the TBMs.

Old Oak Common tunnel

HS2’s shortest tunnel is the 360-metre Old Oak Common tunnel between the OOC station box and the Victoria Road crossover box. Due to its short length and varying diameter at the station approach, this tunnel will be constructed by a cyclic excavation and support method. This uses excavators to dig a short length which is then rapidly sprayed with concrete to stabilise it. Work on this tunnel will start later this year.

Victoria Road crossover box

Although this box is an open structure, it is an integral part of HS2’s tunnels. It forms a launch platform for the Northolt tunnel’s TBMs, provides tunnel ventilation, and houses the crossover before OOC station. This has now become a critical asset as it will be used by every HS2 service whilst OOC is HS2’s London terminus.

The box is 130m long, 24-metres deep, and 42-metres wide at its widest point. The initial design was for a rectangular box, though further optioneering developed its caterpillar shape. This reduced the amount of concrete required by 40% and avoided the need for temporary propping during construction.

The Victoria Road Ancillary Shaft has also been built adjacent to the crossover box. This will provide ventilation, emergency access and house signalling equipment. It has an internal diameter of 25 metres, is 25 metres deep, and was constructed with pre-cast rings at the top, with a sprayed concrete lining at the bottom.

Enabling work to clear the 42,000 square metre crossover box site was completed in March 2019. This was done by a Costain Skanska joint venture and involved the demolition of eight buildings from which more than 98% of waste material was sent for reuse and recycling.

The first stage in the box’s construction was the provision of 77 x 44-metre tension piles to support the base slab (i.e. 19 metres below the slab). Reinforcement for the box’s diaphragm walls was then installed into the ground in 70 discrete panels and concrete for these walls was then poured. Excavation of the crossover box was done in three stages. Firstly, there was a 2-metre excavation to install a capping beam and the top props. A further 13 metres was then excavated for the installation of the intermediate row of props, then the final 10 metres was excavated to the level of the base slab. In total 240,000 tonnes of clay were excavated.

The 3.3-metre-thick base slab was constructed in three different pours. The first and largest pour was of around 1,000 m3 of concrete. Headwalls of 1.5 metres thick were then built to support the diaphragm wall structure when the TBM breaks through the wall.

Northolt tunnels

The 13.6km twin-bore Northolt tunnels face HS2’s most variable ground conditions, with the eastern section being completely bored in London Clay. Yet west of the Greenpark Way ventilation shaft where the TBMs will be extracted, there are gravels, sand, silt, and some quite high-water-bearing areas.

Although the EPB TBMs can deal with such varying ground conditions these tunnels require four TBMs. Two EPB 9.08m diameter shield TBMs are to bore the 5.5km from the Victoria Road crossover box, immediately west of OOC, to the Greenpark Way shaft. The other two TBMs have EPB 9.82-metre-diameter shields which will also finish their bore at this ventilation shaft after boring 7.9km from the tunnel’s West Ruislip portal.

The use of four TBMs reduces the tunnelling time by about 12 to 18 months. Also, the eastern part of the tunnel is slower that the western part can be bored at a smaller diameter to reduce the excavated arisings.

Two TBMs named Sushila and Caroline were delivered to their West Ruislip launch site at the Northolt tunnel’s western portal in December 2021. They were named after local teacher, Sushila Hirani and astronomer, Caroline Herschel. Sushila was launched in October 2022. Caroline started her bore shortly afterwards. At the time of writing, Sushila and Caroline have bored respectively 4km and 3.5km. All four Northolt tunnel TBMs dispose of their spoil by conveyors.

The TBMs that will bore the eastern part of Northolt tunnel have been named after Emily Sophia Taylor, a midwife who became Ealing’s mayor and Lady Anne Byron, an educational reformer and philanthropist. Emily was launched from the Victoria Road crossover box at the end of February. Anne was launched in April.

The Northolt tunnel will have 20 cross passages with fire doors at each end. Construction of these at its western end will require ground freezing and dewatering in view of the soil conditions.

It will have four ventilation shafts from 30 to 40 metres deep. Of these, the Greenpark Way shaft must be built to allow for extraction of the four TBMs. One design constraint was that HS2’s Down line was to be directly under the main line to High Wycombe. During design development, the requirement for HS2 tunnels to be at least one diameter apart was relaxed so that the Down line tunnel need no longer be under Network Rail’s tracks. This allows shafts from both bores at Greenpark Way, with one being a satellite shaft. TBM extraction is possible from both these shafts although the satellite shaft will be capped after the TBM has been removed.

Chiltern tunnels

The 16km-long Chiltern tunnels were almost exclusively excavated in chalk. They are 80 metres below ground level at their deepest point, though are only 20 metres below the River Misbourne, where care had to be taken to monitor and protect the rare chalk stream. The first 200 metres of their long bores passed under the M25 and so necessitated a lot of work with National Highways to get the necessary approval for these bores which resulted in very little ground movement.

Variable density (VD) TBMs with a 10.24-metre-diameter cutting face have been used for these bores. VD TBMs have various slurry face support technologies including earth pressure balance. In addition, these Herrenknecht TBMs offer a continuous tunnelling technique with a newly developed centre of thrust system to more effectively maintain the specified alignment.

These TBMs are named after founder of modern nursing, Florence Nightingale and astronomer Cecilia Payne-Gaposchkin. Florence was launched from Chiltern tunnel’s eastern portal in May 2021 followed two months later by Cecilia. Florence completed her bore on 27 February. At that time Cecilia had completed 98% of her bore. This is an average excavation rate of 15.6 metres per day, though the record was 44 metres in a single day.

The Chiltern tunnels have 38 cross passages, 10 to 15 metres long, and five ventilation shafts, the deepest of which, at Chalfont St Peter, is 63 metres below ground level. There is a complex interface between the 18-metre-diameter ventilation shaft and the twin 9-metre shafts tunnel bores which are 25 metres apart centre to centre and so intersect with the ventilation shaft walls. There are three openings in the tunnel lining at this point. The largest, for tunnel ventilation, is 5 metres high and 4 metres wide. There are also two service openings for cables.

The ventilation shaft is built in advance of the tunnel so that the TBMs can advance through its walls which are formed by 1.2 metre thick Dwall panels. After that, openings are formed in the tunnel wall and the access passageways, with required reinforcement, are created.

Unlike the Northolt TBMs, Florence and Cecilia dispose of their spoil mixed with water through slurry pipes. There are also pipes for water to supply water to the TBM as well as conduits for HV electrical cables.

The slurry treatment plant at the south portal produces chalk cake material for use in HS2’s designated landscaping scheme. The plant’s input flow rate is up to 1,250m3 /h per TBM. On average, it produces 2,650m3 of filter cake per day. There was also a temporary pre-cast segment factory at the tunnel portal which produced the 112,000 segments needed for the Chiltern tunnels.

Long Itchington Wood

The 1.6km twin-bore Long Itchington Wood tunnel protects the ancient woodland above it and was excavated through mudstone and clays. A single VD TBM with a 9.92-metre-diameter cutting face has been used for these bores. This has been named after Dorothy Hodgkin, the first British woman to win the Nobel Prize in Chemistry.

Dorothy was launched at the tunnel’s north portal in December 2021 and completed its bore in July 2022 after seven months. The TBM was then partially disassembled and returned to the north portal. Its gantries were then brought back through the tunnel, whilst nine larger items including the cutterhead (160 tonnes) and tailskin (130 tonnes) were transported by road.

When Dorothy was relaunched in November 2022, it only took four months to complete its second bore in view of the experience gained from the first bore. The 500,000 tonnes of mudstone excavated from both bores was processed at an on-site slurry treatment plant. From there, it was separated out before being transported by a 254-metre enclosed conveyer and used to build embankments along the route of the railway.

Dorothy has since been dismantled and many of her component parts were sent to be reused in the second Bromford Tunnel where the rebuilt TBM has been named Elizabeth.

Bromford tunnel

The 5.8km Bromford tunnel ends 5km from HS2’s Birmingham Curzon Street station. Hence the linespeed through the tunnel (230km/h) is much less than that through Long Itchington Wood tunnel (360km/h). As a result, Bromford is a smaller 8.62-metre-diameter tunnel. It is being bored through mudstone with some sandstone.

An 8.56-metre-diameter VD TBM is being used to bore these tunnels. The first one was launched in August and is named after Mary Ann Evans who is better known by her pen name George Elliot. At the time of writing, Mary Ann had bored 1.5km. A second has been assembled using the gantries and the centre part of the cutterhead from Dorothy. This TBM was launched in March and has been named Elizabeth after Dame Elizabeth Cadbury, who spent her life campaigning for the education and welfare of women in Birmingham.

Green tunnels

Green tunnels are cut-and-cover structures, backfilled above with restored or enhanced vegetation. They shield the local environment and neighbours from the noise and visual impacts of passing rail traffic.

At Copthall, between the Northolt tunnel and Colne viaduct, the HS2 Act specified a deep cutting. However, following a 2018 affordability exercise, it was decided to replace this cutting with a cut-and-cover tunnel. This avoided 400,000 m3 of excavated material and removed the need for off-site disposal of 1.35 million m3 and so has significant programme, community, and environmental benefits. Backfilling above this tunnel also limits long term heave by limiting the unloading effect of the removal of London Clay.

This 600-metre tunnel has a reinforced concrete box structure which is being constructed using innovative wall and roof travelling formwork systems that eliminate the need for formwork cranage. These 40-metre wall and roof travellers also significantly reduce the cycle time for pouring each 20-metre wall or roof sections.

The tunnel design includes several natural ventilation ‘chimneys’ which avoids the need for tunnel ventilation equipment.

North of the Chilterns there will be five green tunnels with a total length of 7.9km: Wendover (1.1km); Greatworth (2.7km) Chipping Warden (2.5km) Long Itchington Wood at the bored tunnel’s south portal (0.1km); and Burton Green (0.7km).

These tunnels are built using a series of M-shaped arches. The arches are made up of five precast units which are 20.4 metres wide, 2.5 metres long, to form two 8.4-metre-high tunnels. At Chipping Warden and Greatworth these are placed on a 300mm reinforced concrete base slab, at other tunnels this slab is cast in situ. The tunnel is waterproofed using a double layer, compartmentalised membrane system which is placed in position by a bespoke gantry system. The M-arches are then backfilled to the depth required by the local topography. The deepest section, at Chipping Warden, has 18 metres of backfill.

Fire door openings in the centre wall are provided every 300 metres for train evacuation. In common with the TBM tunnels, the green tunnel will have 100-metre-long, progressively porous portals, to reduce noise from the pressure waves as trains enter and exit the tunnels at 360km/h.

Tunnel lengths

On the UK’s 16,000km rail network the total length of its tunnels is 186km which is around one per cent of the network. Britain’s 19th century railway builders tried to avoid expensive and difficult tunnels which were then generally only necessary to build a reasonably level railway through challenging terrain. Early railway builders generally did not have to contend with a dense built environment.

Those who planned phase one of HS2 faced not only extensive built up areas but environmental pressures to build green tunnels. As a result, of HS2’s 208 route km, 52.2km (25%) is in tunnels. As shown in this feature HS2’s tunnel engineering is impressive, yet tunnelling is an expensive option.

At the time of writing HS2 has completed 46.3km of its 75.9km of bored tunnels. Readers who wish to follow the progress of HS2’s tunnelling can do so at https://tunneltracker.com/.

Lead image credit: HS2