Looking back over several years of articles written for Rail Engineer covering the European Train Control System (ETCS), it is somewhat depressing to observe that none of the predictions for system introduction have come to fruition in the timescale stated or at the forecast price.

Right across the world, national railways have struggled to implement ETCS systems for many different reasons, which include technology, operating rules, cost, and train fitting. Only Belgium, Netherlands, Denmark, Switzerland, and Norway have committed to nationwide roll out, and these are progressing. All have relatively small route kilometres compared to countries such as the UK, France, or Germany, and have a supportive regulatory regime.

The UK rollout has been markedly slower than many other countries with only the Cambrian trial site, the Thameslink central core, and the spur from the GW main line to Heathrow airport being operational. Papers given at conferences over the last decade have predicted a much greater implementation of ETCS than has been achieved. The much-publicised East Coast Digital Programme (ECDP) is making progress and the Finsbury Park to Moorgate section will be fully commissioned in 2024 with the rest of the route between Kings Cross and Stoke Tunnel (near to Grantham) taking until 2029 to become completely cut over. Thereafter, the master plan shows it will not be until the late 2030s that anywhere near a multi-route rollout will begin to happen.

Issue 202 (May/June 2023) gave an insight into some of the thinking and planning, but additional information has since been gleaned that highlights the difficult cost pressures associated with ETCS roll out and where some drastic support will be necessary.

What is the problem?

Nowhere in the world is the railway’s commercial structure more complicated than in the UK. With the multiplicity of organisations involved – government, Network Rail, train operating companies, freight companies, open access operators, rolling stock leasing companies, heritage interests, local authorities – all of whom have a vested and financial interest as to how train services should be provided.

It is small wonder that planning ETCS systems that satisfy all parties is something of a minefield.

Three big challenges emerge:

- Organising the industry to produce sensible commercial structures. Improved and more realistic regulation is of paramount importance, especially where large strategic projects are being planned and developed.

- Developing supplier engagement and operator capability to support such network-wide strategic developments.

- Obtaining a breakthrough in how key activities like train modifications, system proving, integration of approvals, and the undertaking of driver and signaller training are all progressed.

All these add cost to the project and have to happen. They must however not become dominant within the project financial structure otherwise the pace and method of delivery becomes seriously compromised.

The ECDP has developed a novel partnership model and a user centric methodology that bring operations and engineering together to address these core challenges.

Rolling Stock Complications

It has been said on numerous occasions that retro fitting rolling stock with ETCS (or indeed any other technical addition) is not the preferred approach. The ideal situation is for trains to come out of the factory ready fitted but, even if this is the case, upgrades to either the hardware or software are likely to happen during the lifetime of the train.

In the UK, it is rare for Train Operating Companies (TOCS) to own their own trains and normally these are leased from a Rolling Stock leasing company (ROSCO). In such instances, the maintenance and performance issues of the train become the responsibility of the TOC who will finance the updating of the train over the lease period. This is relatively straightforward but raises discussions whenever a new system such as ETCS is imposed on the route, and it is usual for the imposer (in the case of ETCS this is Network Rail on behalf of the industry) to bear the cost of the upgrade. The leasing cost is unchanged or changed only very marginally.

The situation is more complex where trains are procured by the government under a Private Finance Initiative (PFI) with a rolling stock supplier and typically a range of financiers. Associated with the deal are significant conditions as to how the train is used, maintained, and made available for service. The leasing cost is high and the penalties for non-availability are onerous. Taking trains out of service to equip them with minor changes, let alone ETCS, is regarded as high risk which acts as a deterrent to making the change. Thus, the cost of implementing the change is artificially higher as a result of the penalty and risk regime imposed. The implications are significant for projects that need to make changes to trains.

Implications for the ECDP

At face value, the rolling stock situation on the ECDP should be relatively easy. The Class 800 Azuma intercity trains were all built with ETCS ready fitted. Similarly, the Class 717 inner suburban units that replaced the 313s were equipped with ETCS as part of the build contract, but even here some minor software changes will be needed. More difficult are the Class 387 Electrostar trains as these need to be retrofitted – a task made harder by the very small cab resulting from the inter unit corridor connection.

That said, a successful retrofit is being progressed with Alstom and Govia Thameslink Railway (GTR) as an efficient and directly managed proposition. The Thameslink Class 700 trains that run through to Peterborough and Cambridge from south of the river already use ETCS with Automatic Train Operation (ATO) superimposed for the London central core from London Bridge to Finsbury Park and Kentish Town. In theory, these should require only minimal work to adapt for the ECDP (see later paragraph). For freight, the Class 66 locomotives are going through the process of ‘first in class’ so it should be relatively easy to equip a number of these even if it means creating a small captive fleet.

There will be a challenge north of Peterborough where DMUs operated by East Midlands Railway run northwards to Grantham as part of the Norwich Sheffield Manchester service. These will either need to be fitted as a sub fleet or perhaps by that time a new build of trains will be in service with ETCS provided as part of the contract.

However, both the Class 700 Thameslink trains and the Class 800 Azumas were acquired via a PFI deal, which for the reasons stated above have made their upgrade a serious challenge. Carrying out the technical changes is relatively straightforward, but it is a major commercial exercise where clear thinking and willingness to succeed from all involved is required.

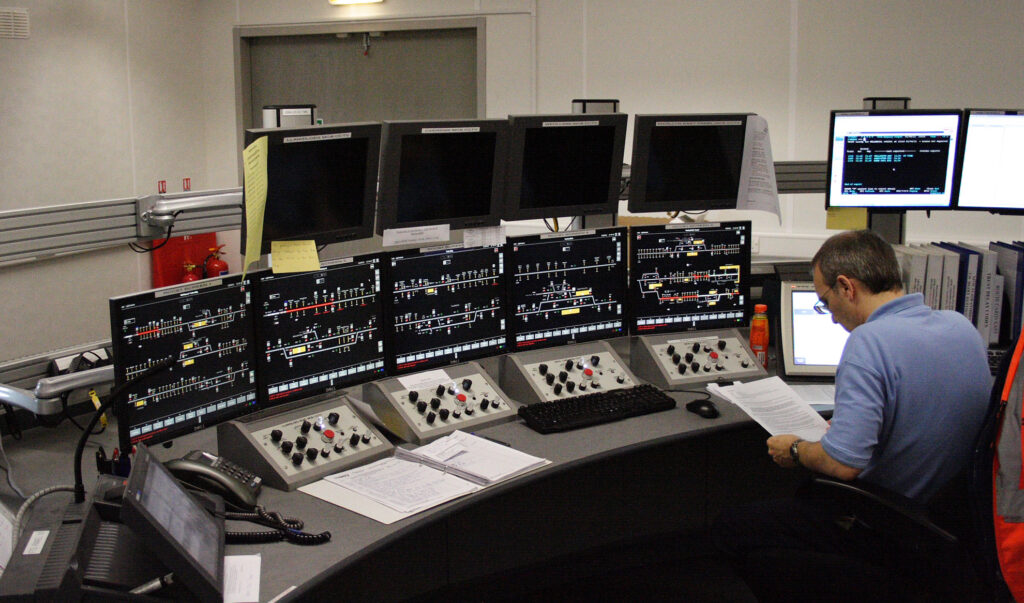

Drayton Park.

The Class 700 Conundrum

When commissioned in 2018, the full Thameslink service revolutionised north-south cross London journeys. With the potential for 24 trains per hour in each direction, reliance on manual driving was not deemed possible for this to be achieved, so ETCS with an incorporated ATO package and short block sections was seen as highly desirable. The ETCS software specification had been signed off at European level at v3.3.0. This boded well for extending ETCS along the East Coast Main Line, the Midland Main Line, and eventually to routes south of the river. The system has proved reliable and the ATO works well.

A recent contract has, however, been announced to upgrade the Class 700 trains with a later version of ETCS, incorporating some hardware and software changes so as to be compatible with the national reference design specification being matured through the ECDP delivery phase. The contract value is £32.7 million which, for the 115 trains in the fleet, works out at £140,000 per cab. This is an enormous sum of money for a train already equipped with ETCS, albeit the development applies to other fleet variants like the Class 717.

The press release states the upgrade will include:

- Software upgraded to v3.6.0. After v3.3.0, a newer version, 3.4.0, was introduced to aid maintenance but did not have backward compatibility to v3.3.0. Seen as low risk, the UK agreed to this. V3.6.0 is a further version but does have backward compatibility to v3.4.0.

- Upgraded driver-machine interface screen modules improving the safety integrity level of the system.

- Packet switching to support ETCS data transmissions on the Euro Radio. This is part of the on board European Vital Computer (EVC) but is separately packaged as hardware. During the Thameslink design, packet switching was considered but analysis showed that sufficient radio spectrum was available for circuit switching (namely, a continuous connection to each train) and thus less of a risk. Spectrum availability on the GSM-R network once the ECDP is introduced is less certain for circuit switching, hence the need to go for packet switching which uses radio frequencies more efficiently.

- Cold movement detection. This is needed to validate a train position after the train is shut down after its daily operation. The position of the train on a Class 700 is memorised but not validated. If the train has not moved, validation will now take place automatically. This facility is not part of the TSI and it was up to each ETCS supplier to decide what to provide. Optical correlation is one method to prove a train has not moved and it is presumed this is what will be adopted for the Class 700s.

- KLIP interface module change. This is the input/output interface to the Driver Machine Interface, viz the cab display unit. Previously this had its own intelligence but now only requires an interface to the EVC.

- Software update for the train’s data recorders. The need for a judicial recording unit is in the ETCS specification with a defined protocol as to how data exchanges are captured. If the recorder does not conform, a Notified Body (NoBo), now reclassified as an Approval Body (ApBo), will request a modification to be made. This is the case with the Class 700s as, despite Brexit, the UK has chosen to continue in the adoption of European standards.

- New wiring to the train databus.

The requirement to make these changes is considered essential at some point in time, as the functionality of the ETCS will be deficient if the work is not carried out. The work is not associated with the safety of ETCS operation, and the trains could still operate on the ECML.

The impact of PFI is the main reason for the high cost. While there could be some ‘sharpening of pencils’ with some of the engineering elements, the changes to the cab and the software updates have to be incorporated into the current PFI and its associated performance and penalty regime. Carrying out all these things within one upgrade is preferable to doing them separately which would only create more complex commercial interfaces where core safety operational systems are partially in and out of the regime. It will also mean a new ‘first in class’ exercise has to be carried out. Once proven, trains will need to be taken out of service for the modifications to be made, all of which impacts on the PFI contract for train availability and performance, thus incurring costs.

The question that needs asking is why the upgrade cannot be undertaken during the times when the trains are in for routine maintenance? It is understood that the way in which costs are incurred for the PFI financed rolling stock is being challenged by Network Rail as the infrastructure manager.

Interoperability and backward compatibility

It is recognised that ETCS technology will evolve over time and that periodic updates will be necessary to keep offering additional features as they become available. This should not mean that the entire nationwide infrastructure and train fleets have to undergo upgrades for the system to operate safely and successfully. Just imagine the complexity of even trying to do this when the infrastructure and train borne equipment is supplied by many different design and manufacturing companies.

The idea of interoperability is that everything works with everything else, regardless as to who made what, but backward compatibility must also be part of the equation to ensure that older marques of equipment can continue to function. It is a little bit like the domestic computer business where earlier generations of, for example, Word or Excel can still be compatible with later versions of the programme, thus enabling day-to-day business to go on.

It would be easy to raise alarm bells that if retrospective modifications are needed every time an updated version of the ETCS spec is introduced, it triggers the need to modify rolling stock across a nationwide ETCS network. This would become an expensive logistics nightmare with the concept of backward compatibility being flawed. Fortunately, reliable information would indicate that the functionality curve is flattening and future ETCS enhancements will not need to be retrospectively fitted everywhere.

Costing a signalling project

If ETCS is to be the bright future for main line control and command systems, then it has to provide a greater degree of safety, an enabler of greater capacity but more importantly, to be cheaper than conventional signalling with lineside ‘lights on sticks’.

As indicated in previous articles, a conventional signalling project is assessed for value around the basis of Signalling Equivalent Units (SEUs). These are calculated by the length of route, the number of tracks, and the quantity of points, signals, track circuits or axle counters, and such like. Level crossings tend to be outside the equation and treated separately. After the design, manufacturing, installation, testing, and commissioning tasks are priced, when integrated with the above quantities, the cost of an SEU can be calculated. It is the high price of an SEU that is causing concern in the ORR.

However, the equation does not work for ETCS as much of the signalling kit is train borne and thereby new calculations have to be devised. The factors involved are described above, viz, first in class development, train fitment costs, time out of service costs, number and types of trains to be fitted, whether to create a captive fleet, driver and operator training, all of which are primary considerations in the early stage of network migration and have to be taken into account in the long-term costings.

Even for the infrastructure, the ultimate goal is to remove the lineside signals as retention of these will only worsen the costing structure. Conventional signalling ‘islands’ have been talked about in the past where signals would be retained to accommodate non fitted trains at places such as Crewe, Leicester, York, and many others where routes cross and where trains would not be fitted.

At least one re-signalling project where ETCS has been a consideration, will stay with conventional signalling as the scale of fleet change for ETCS was shown to be prohibitively expensive. North of the border, the Scots have declared that investing in electrification is the policy priority. One might speculate that if new electrification were to lead to new fleets of train that come with ETCS fitted from the factory, the case for equipping a route with ETCS would be much stronger.

Future predictions

For ETCS to achieve nationwide acceptability, it must become easier to implement. The central objective is reduced signalling infrastructure costs, but capacity gains predicted by using ETCS are mainly pertinent for the very busiest of routes as normal lineside signals are capable of handling two-minute headways. Equally, for high-speed lines, the need to replace signals with in cab movement authorities is a necessity, as human reaction times cannot reliably cope with reading signal aspects at the lineside. Just how many high-speed lines will the UK be building in the next two or three decades given the experiences and the now declared scaling back of HS2?

The commercial scenario and regulatory regime for ETCS adoption is the major part of the problem, and a strategic review as to how this can be strengthened to accommodate large strategic projects such as ETCS is urgently needed. A realistic approach to risk taking and minimising any associated penalties must happen otherwise the projects will falter.

The Class 700 contract might just be a wake-up call for the future as there will be many more situations where train equipment upgrades are seen as necessary. The big one looming on the horizon will be upgrading the train radios and infrastructure from GSM-R to FRMCS. Maybe Great British Railways will get a grip of this and produce a sensible financial outcome.