There has been much criticism of the ride comfort of the most recent trains brought into use on the British rail network such as the class 8XX Inter City Express Trains (IET). Critics compare them unfavourably with older trains which, they say, deliver a superior ride. When travelling around the UK in 2022, your writer particularly noticed that IETs sometimes rode well and sometimes were extremely rough, so this is probably not entirely a train issue. Critics have also complained about uncomfortable seats (Issue 176 – July 2019), and these are clearly part of the perceived problem.

Passengers’ perception of ride comfort arises from a combination of their reaction to the accelerations they feel in three dimensions, and other issues such as noise and temperature. Ride comfort may be more subjective than objective, but there continues to be research to understand the contribution of the various factors to a ‘comfortable ride’ – vertical, lateral, longitudinal accelerations and jerks, together with noise. Illustrating this with one scenario, which does the passenger perceive as worse – general disturbance of the vehicle traversing points at speed or the same with much clattering from somewhere underneath the vehicle?

This article is in three sections. First, a case study of a 30-year-old fleet that was criticised for a poor ride when new but was improved; second, exploring some of the factors that might explain why we achieve a less good ride on modern trains compared with, for example, those in the case study; and third, what can be done to improve the new trains.

Case study: Mark 4 coaches

Mark 4 coaches were built by Metro-Cammell in the late 1980s and featured SIG type BT41A bogies. In service, the fleet was criticised for poor ride. British Rail management of the day accepted the criticism and determined that something needed to be done. As far as Rail Engineer is aware, the specification/requirements had been complied with, but it was clear from contemporary commentators (Roger Ford et al) that the ride was not good at 125mph, although there were reports that all was fine at the specified 140mph.

Investigation involved measuring accelerations using tri-axial accelerometers and recording equipment (such as is used for measuring the ride comfort of IMechE Railway Challenge locomotives) at various locations along the vehicle floors. This equipment is simple and straightforward to use. The analysis of the data indicated two problems.

First, there was a great deal of relative lateral movement between coaches especially noticeable if negotiating the inter-car gangway. This was the first time that the two halves of the gangway were physically connected and there were no friction-mating faces that would have provided a level of friction damping. The problem was resolved by fitting a transverse hydraulic damper underneath the gangway with one end connected to one coach and the other end to the next coach. The damper also improved the overall lateral ride.

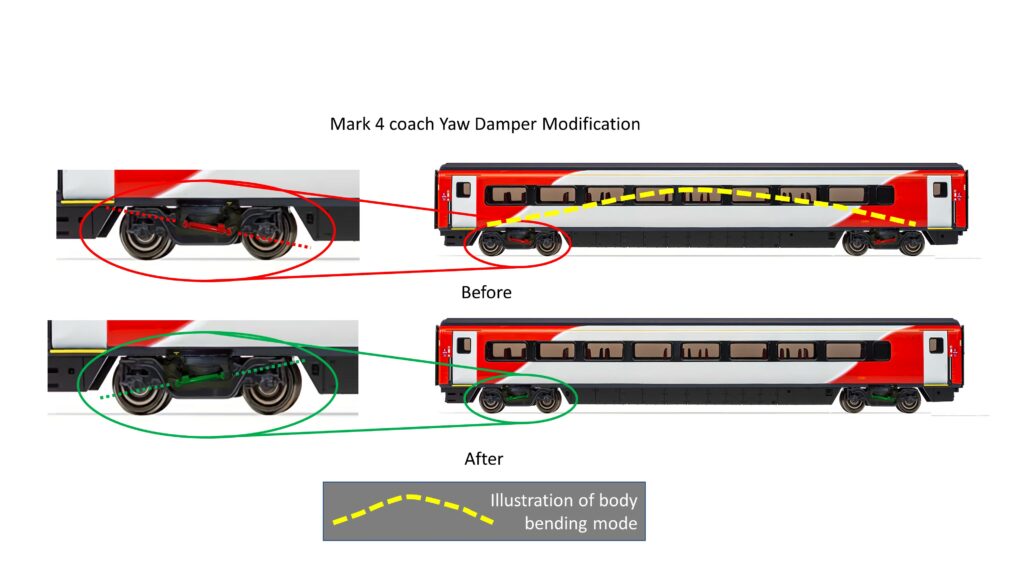

Second, it was found that the yaw dampers mounted on both sides of the bogies were exciting the first vertical body bending mode. This is illustrated in the diagram showing the original orientation of the dampers as a red line and the body bending represented by the yellow dotted line.

Engineers investigating this believed that if the damper mounting location could be changed slightly, the problem would be reduced or rendered ‘mostly harmless’. The agreed modification was for the bogies to be turned though 180 degrees, meaning that the yaw dampers faced toward the coach centre rather than the end (the green line on the illustration). With the support of the supplier who had the models, the solution was ‘tested’ using vehicle dynamics multi-body computer modelling and shown to be effective. Simulations are often part of the solution, and they can really only be done by the supplier, the organisation that understands how the suspension works, the detail of which is key to effective simulation.

It was necessary to reposition the yaw damper body mounting bracket from the outer to the inner side of the body bolster, a comparatively straightforward modification. This is the configuration that will be seen on the remaining mk 4 coaches in use today, although observers will note that the shorter Driving Van Trailers retain the original yaw damper layout as they react to the yaw damper differently from the longer passenger cars.

Why do we achieve a less good ride today?

There are three main reasons: compliance culture, organisational complexity, and lack of a guiding mind.

Compliance culture

Engineers ‘of a certain age’ often say “standards are for the guidance of wise men [appropriately dating the saying] and the blind observance of fools.” These days it is apparent that demonstration of compliance with the requirements (procurement specifications, National Specifications, Standards etc), is all that’s required. Requirements are generally SMART – Specific, Measurable, Achievable, Relevant, Time-bound – whereas aspects such as seat and ride comfort are subjective. As an example, the original UK Government IET specification called up sections of line on which a specified ride quality was to be achieved (although, curiously, this included a section where the trains were not required to operate).

The various specifications and standards permit the ride quality requirements to be demonstrated by simulation, as providing a track for physical testing that actually meets that specified at procurement is fraught with its own issues. This begs the question whether simulation adequately replicates all the factors involved in delivering ride comfort (see panel). But can it be said that this fully replicates what the passenger experiences? Does simulation model seats and noise paths, for example?

Organisation complexity

In the case study above, there were just two parties: British Rail and Metro Cammell. By comparison, the original IET contract involved the following players:

- Specifier and Procurer: Department for Transport

- Supplier: Hitachi

- Owner: Agility Trains

- Infrastructure Manager: Network Rail

- Operator: LNER and GWR

Along with these were a number of roles provided by one or more independent organisations (often procured by the train supplier) to certify compliance with: Technical Specifications for Interoperability (as was the regime of the day) – Notified Body; Notified National Standards – Designated Body; and Common Safety Methods (risk evaluation and assessment; monitoring; safety management system requirements; supervision; common safety targets; conformity assessment) – Assessment Body.

Which of these organisations feels the pain sufficiently to commit management time and funds in order to investigate and deliver a fix? One can imagine the operator going back to the supplier, being told that the train is good as it has been independently certified as compliant with requirements, pointing to a possible track problem. Conversely, an approach to Network Rail will show that its track is consistent with the specified quality. Inevitably a multi-party investigation is required but, with the current contract structure and financial constraints, is anyone likely to be able to get permission to fund the investigation, let alone any modifications?

A multi-party investigation did take place with the IET bolster/lifting pad cracking issue, and it seems that the parties only come together jointly to resolve a problem when there is a safety issue.

Lack of a guiding mind

In BR’s day, one of the guiding principles of the organisation, certainly by the late 1980s, was delivering quality for passengers. This would have infected the culture of the place and, when the issue with the Mark 4 coaches was identified, one can imagine that the Inter-City director of the day would simply have told the project engineer to sort it out, although remembering some of the engineers involved, they were probably already on the case. The project engineer would have involved the train supplier and the track engineers and would have been able to rely on the support of BR Research experts. But who would do it today? One might expect the train operating company (TOC) to be the organisation that wants to delight the passenger but even prior to Covid, when franchising contracts were still recognisably revenue/profit driven, the TOCs concerned were not in the driving seat. Their contracts effectively said that they would operate the trains that had been purchased and approved for them. They were unable to influence seat comfort, for example.

What could be done?

Part of the cure is to acknowledge that the best simulations in the world and compliance with standards only get you to the starting gate. When the train starts running on the track, reports of poor ride, from staff or passengers, need to be taken seriously – an acknowledgement that something is wrong. From there, work can proceed to diagnose the problem. This would probably start with the same measurement methods that were used on the Mark 4 coaches. Only when that data set is available can engineers start to understand what is causing the poor ride and what might be done about it.

It might be that the train is sensitive to particular track features and some work on the track might be cost-effective. Equally, a train fix could be as simple as tweaking damper rates. The information would also help to understand why the simulation did not predict the problem, for instance if there was a deficiency in the specification or that someone made a mistake.

Another simple improvement would be to make the seats more comfortable at the first occasion when they need recovering. It is possible to have comfortable seats on these trains; those on the Lumo trains seem to be well regarded, for example.

The question is whether there’s any possibility that this will be done? Even the outline proposals for Great British Railways (GBR) are unclear whether it will be GBR itself or its contracted operators whose role it will be to delight passengers and hence have the incentive to make improvements to passenger comfort. But, if the aim of GBR is to re-unite the wheel and the rail, we could argue that part of the demonstration of a good wheel/rail interface is passenger comfort.

Conclusion

While this article sets a fairly gloomy tone, there is hope for the future. We have already seen complaints about ‘ironing board seats’ prompt research into objective ways of specifying seat comfort, albeit still with a level of subjectivity involving a passenger assessment process. The standard on ride comfort, EN12299, provides tools and methodology to investigate ride comfort issues when applied in an appropriate way. One also hopes that University of Huddersfield’s work with THOMoS (Issue 195 – March/April 2022) will lead to better understanding of the impact of particular track/suspension interactions on passengers’ perceptions of good and bad ride, and that suitable requirements can be framed to achieve better results.

Panel

There are a lot of elements that contribute to ride comfort: track geometry; wheel profile; primary suspension (springs/dampers/bushes); bogie stiffness; secondary suspension (vertical and lateral); yaw dampers; body stiffness and bending modes; inter-vehicle effects (longitudinal coupling stiffness and yaw between vehicles); anti-roll bars; traction and braking jerk control; and noise paths.

A smooth stable ride can only be achieved through careful optimisation of all the components between the track and the passenger’s feet or buttocks. Vertical, lateral, longitudinal, yaw and roll all work towards this objective. But there are often competing objectives (staying within gauge for example) that prevent the designer simply optimising the suspension for the best ride.

If the track is smooth, the train’s suspension has an easy time. If the track is less smooth, a good ride can still be achieved but softer springs might be required. But softer springs bring more suspension movement which might mean the body has to be a little smaller, which, in turn, might affect the accommodation. Softer springs in the vertical direction lead to more roll on curves, and anti-roll bars might be provided to control roll, particularly on vehicles where pantographs are fitted. But anti-roll bars can also introduce a transmission path for noise and higher frequency vibrations if the selected bushes are not perfect.

Computer simulations to demonstrate vehicle safety and stability are sophisticated but inevitably they do not take account of absolutely every factor and do not account for noise transmission at all. Car bodies and bogie frames might be assumed to be rigid, for example. Yet, as the case study explains, car bodies are flexible, and this can affect ride with longer vehicles tending to have lower bending frequencies more likely to be detectable by passengers. Depending on exactly where attached, component mounting points can have an impact on the overall ride performance.

Finally, ride quality is a system property and not determined by the train alone.