What if there was a tried and tested solution to speed up trackside drainage times by a factor of 10, simultaneously reducing installation costs and improving site safety by halving the depth of trenches and the amount of crushed stone required? This method has been adopted by the highways industry for over 20 years, but fellow major linear asset engineers in the rail industry are yet to realise the same advantages.

This winter’s record rainfall and widespread flooding brought the issue of trackside drainage into sharp focus. Large sections of the network were inundated, flooding tracks and causing numerous embankment slips.

The scale of disruption highlights the importance of effective drainage systems. They must be able to resist high static and dynamic loads and be fully maintainable over a design life in excess of 60 years to provide the best whole-life cost.

As most drainage systems in the UK are installed during remediation, where time is limited, speed of installation is also a very significant factor.

Traditional cess drains

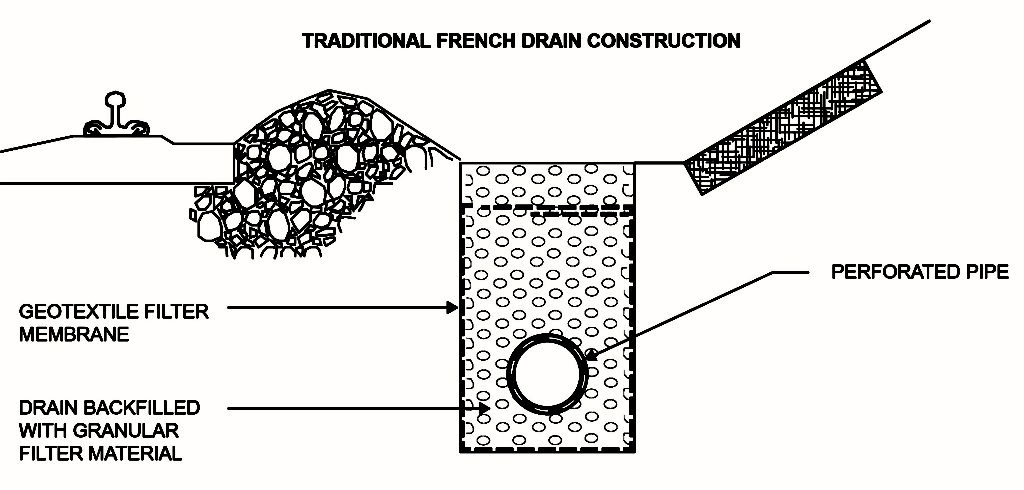

Current trackside drainage is reliant on cess drains, consisting of cut trenches, filled with crushed stone, below the sleeper level, either side of the track.

Excavating traditional cess trenches for drainage pipes and lining the sides of the trench with geotextile, prior to backfilling with crushed stone, is a relatively expensive and laborious process. Trenches deeper than 1.5 metres must be shored for support, prolonging the time that ‘boots are on the ballast’. Then there is the cost of disposing of the arisings and procuring new stone.

In addition, crushed stone is not a particularly efficient drainage material, since it interlocks when compacted, leaving very little void space for water flow.

Alternative solution

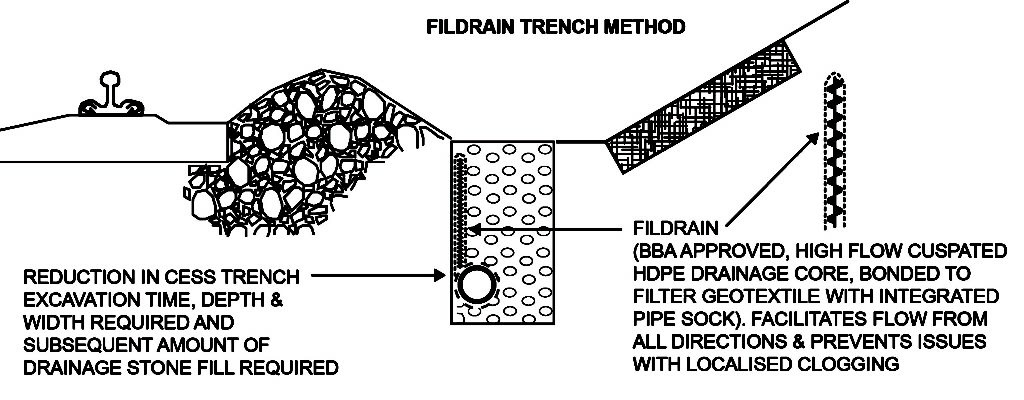

The realisation that it is the void space within a layer of crushed stone that achieves the drainage flow led to the development and specification of Fin drains or Fildrains, polymeric cores that have a high void ratio.

ABG Fildrains are a preformed drainage layer comprising a high-strength, lightweight HDPE (high-density polyethylene) cuspated core, laminated with geotextile. Fildrain has a flow capacity many times that of traditional crushed stone, owing to the unique open structure created by the dimpled core profile, allowing unhindered water flow.

The cuspated core of Fildrain at just 7mm thick – when tested under simulated site conditions – achieves an in-plane flow capacity of 1.0 l/m/s at a hydraulic gradient of 1. This is eight times that of a 500mm layer of drainage stone. It is the reduction in layer thickness, and the narrower trench widths required, that enables the geocomposite drain to achieve project time and cost savings, reducing closure times and the number of trackside deliveries required.

Fildrain has many applications in railway cuttings, cess and embankment drainage and is BBA approved, meeting requirements for load resistance, maintenance and fast installation. It is simply installed into narrow trenches, with the excavated soil replaced as the backfill and then topped with a thin layer of crushed stone. Fildrain is supplied in a range of heights to suit each application and for easy connection to existing drainage systems.