One of the biggest design challenges for power supply manufacturers in a global rail industry is that train-borne applications around the world have different battery voltage parameters across different vehicle classes. Manufacturer Cincon developed the EC7BW18-72 board-mount 20W DC-DC converter series which includes models for all common voltages, from a single 12V battery for automotive vehicles up to 110V systems for electric trains and an ultra-wide input range of 8.5-160V DC.

Now the converters are available as a complete solution in a one-size-fits-all format for all voltages and all classes of trains. The EC7BW18-ECRT/EDRT 20W universal input DC-DC converters are a turnkey solution for power for the railway industry. Available from Relec Electronics, the power supplies are available in chassis and DIN-rail mount formats.

The EC7BW18-ECRT/ EDRT DC-DC converter.

The company developed the DC-DC modules as an all-in-one 20W power solution suitable for system engineers as well as board-level designers. The family has been developed around the proven EC7BW18-72 series 2” x 1” DC-DC converters, with the addition of a rugged case and additional components.

As well as reducing time to market, the EC7BW18-ECRT/EDRT series saves ‘bill of materials’ costs because they do not require additional components. The converters meet the requirements of EN50155, EN50121-3-2 and EN45545-2 for immediate use, presenting a turnkey integrated solution for system designers.

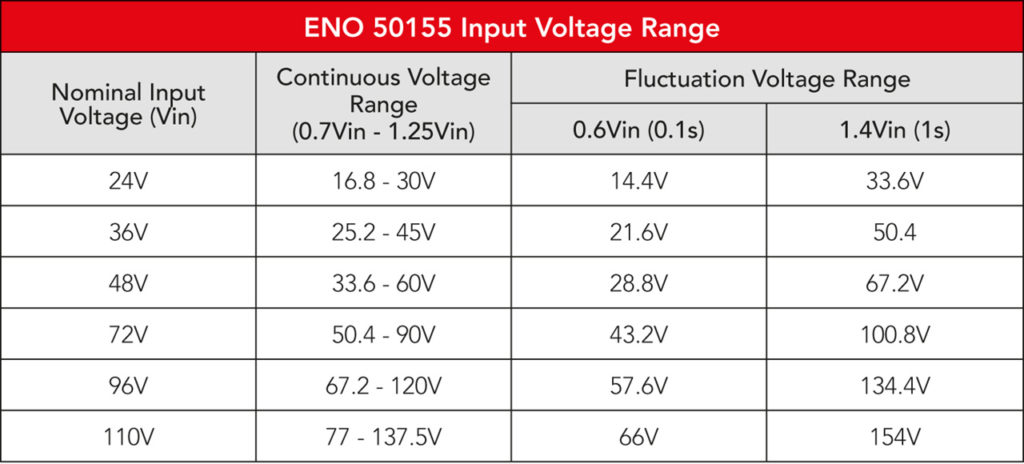

Instead of multiple power supplies, a single unit with an input range of 10-160V is capable of meeting the nominal input ranges from 24-110V for EN50155. In addition, each module will also meet the requirements of RIA12 surge A (3.5 x Vin for 20ms) for 24V and 52V systems. This represents savings in inventory as well as ease of design for international manufacturers.

Construction

The DC-DC converter series has been designed to be compliant to EN50155, with built-in inrush current limiter, hold-up circuit and EMC solution to EN5021-3-2 integrated into a single chassis or DIN-rail mounted package.

In order to comply with EN50155, a device must pass a number of type tests relating to temperature, humidity, vibration, shock and electrics. These simulate the harsh environments and conditions encountered in train-borne operations.

The EC7BW18-ECRT/EDRT series has been passed as compliant for all the tests (for example, low temperature start-up, rapid temperature variation and EMC testing) under all input voltage ranges.

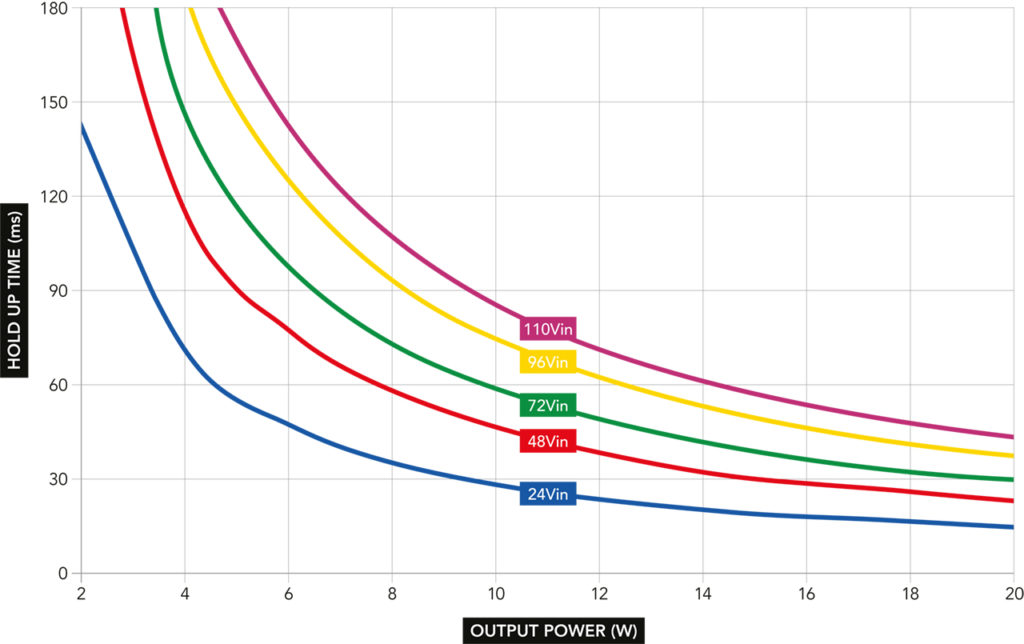

In order to meet the power supply tests, a turnkey product has to be able to provide ‘hold up’ of the output for a period of time after the input supply disappears. This can be done simply by adding capacitance at the input side. However, the transient characteristic of a capacitor will cause higher inrush currents at the input side during switch-on. If there is no action to restrain the inrush current, it can result in a voltage drop at the front-end of the converter or trigger the over-current protection of the input circuitry, leading to no output from the converter.

Using its design expertise, Cincon has integrated a built-in active inrush current limiter which has higher efficiency performance with less impact from the ambient temperature when compared to a passive inrush current limiter.

Supply interruption

In railway power systems, it is common to see the input supply voltage experience short-term fluctuations due to disturbances within the generator, battery or pantograph system. These can also cause short periods of open circuit or short circuit at the input. EN50155 power supply tests simulate the interruptions of voltage supply and supply changeover, and are categorised into five classes:

- (Interruptions of voltage supply)

- Class S1 – no voltage interruption; no performance criterion is requested, but the equipment continues to operate as specified after the voltage interruption

- Class S2 – interruption time 10ms

- Class S3 – interruption time 20ms.

- (Supply change-over)

- Class C1 – at 0.6Vin during 100ms, without interruptions

- Class C2 – during a supply break of 30ms.

In order to meet the requirements of Classes S2, S3 and C2, additional capacitance is required at the input side of the DC-DC converter. When the input voltage is lower, the required capacitance value will be higher; conversely when the input voltage is higher, the working voltage of the capacitors also needs to be higher. The EC7BW18-ECRT/EDRT has a hold-up circuit which meets the requirements of S2 (limit @24V <14W), S3 (limit @24V <10W) and C2 (limit @48V <15W).

To protect against misuse and over-stressed operation, the EC7BW18-ECRT/EDRT modules feature reverse-polarity protection, over-temperature protection (unit switches off when the case temperature exceeds 106 degrees), over-current protection (short circuit and overload), input under-voltage protection (prevents very high input current at low Vin) and output over-voltage protection (secondary protection against an internal feedback failure).

Article Written by John Stone, Sales Director, Relec Electronics.