Folkestone was once an important harbour and shipping port. Nowadays, it is home to Dollands Moor freight yard which was built to serve the Channel Tunnel. The Dollands Moor DC Substation sits at the western end of this freight yard and was originally constructed as part of the Channel Tunnel Reinforcement Scheme in the mid-1990s.

Network Rail decided to remove Dollands Moor DC Substation from service at the end of 2019 due to water ingress, reliability of DC protection relays, unavailability of spare parts and lessons learnt from the Godinton Substation incident where a Network Rail colleague was seriously injured. Since then, the substation was watching trains passing by without being able to contribute to the network. However, its fate was changed when Network Rail initiated the works to bring the substation back to operational service to improve the performance of the DC network.

Network Rail deemed Dollands Moor as a high priority and required the project to be completed as soon as possible. BAM Nuttall, as the principal framework contractor of Network Rail, immediately started the planning. The company was aware of the level of complexity, the tight deadlines and the significance of the project; hence it had to ensure that the designer has high expertise and resource to cope with those challenges. Rail Power Solutions, being one of BAM Nuttall’s preferred Electrification & Plant (E&P) designers, was approached to develop this highly challenging design.

Retrofit to increase safety

According to the Godinton report, concerns were identified with the existing DC switchgear, combined with the formation of condensation which contributed to the incident. Dollands Moor DC switchgear was chosen as a trial site for undertaking design and implementation works to improve its reliability, electrical clearances, and maintainability. In addition, there was a requirement to extend the asset life for a minimum of 15 years.

The DC switchgear, which was installed in the 1990s, has a protection system that does not comply with the current Network Rail standards. Network Rail’s preference was to replace the complete protection system including the DCTR-1B protection relay, Hall effect transducer for current measurement, Hall effect check transducer, Hall effect sensor, Hall effect power supply unit/amplifier, and DC voltage transducer. This means redesigning the majority of the non-removable parts of the DC switchgear.

An alternative solution was the complete renewal of the DC module which would come at a significant cost. However, given the vast number of this type of DC circuit breaker on the network, a retrofit option applicable to the majority of the breakers was considered a more cost-effective approach.

Following multiple options proposed by Rail Power Solutions during the GRIP 3 stage (option selection), Network Rail agreed to a single option that provides a practical retrofitting solution without compromising on safety. The design included works in track cable termination, relay and transducer chambers.

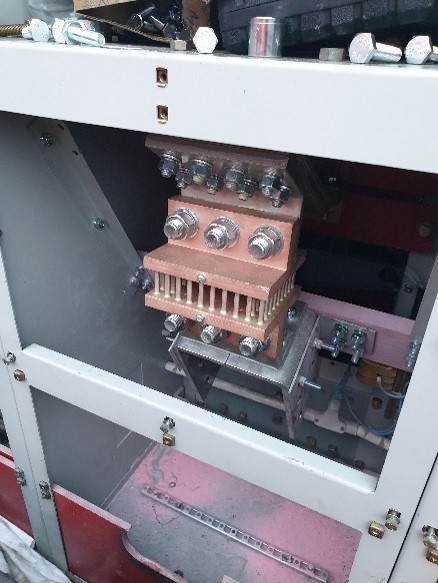

“Dimensions were obtained on-site to develop the design. However, the partial use of existing copper work with a different configuration, installation of an additional shunt, and the requirement for additional angled copper work introduced significant uncertainties. It is like playing a 3D puzzle, but you have to create the puzzle pieces. Although we were confident of the design, timescale and cost implications were the last thing we wanted during the construction phase. Assembling the real scale 3D parts on-site helped us to identify any details we missed and to confirm the accuracy of the dimensions.” William Fonseca, Director of Rail Power Solutions.

Design challenges and innovations

The configuration of the copper work of the DC Switchgear at Dollands Moor created concerns about the space available for the installation of new equipment within the cable chamber. The design became more challenging due to the absence of record drawings showing the exact dimensions of the existing copper arrangement in the cable chamber. Rail Power Solutions had to attend the site multiple times to confirm the suitability of the proposed shunt and copper arrangement.

Following discussions with BAM Nuttall, the parties suggested introducing innovative technology into the design process using 3D copies of the shunt and proposed copper work to check effectively the suitability of the new arrangement before finalising the design. Given the very short lead times for 3D prints, it provides more flexibility and is time-saving and cost-effective compared to supplying the actual copper parts and shunt during the design stage.

Rail Power Solutions produced the 3D model of the parts using the dimensions obtained on-site and got the parts 3D printed. On the next visit to Dollands Moor, the engineers were more confident in the design since the 3D model showed that the proposed copper work and shunt would precisely fit the cable chamber.

“A collaborative team effort from all at RPS, BAM Nuttall, and Network Rail. Despite the short time frame, a challenging project was delivered.” BAM Nuttall contracts manager, Duncan Hall.

Safety first

Rail Power Solutions’ primary design objective was to make minimal modifications to the existing copper work to reduce the retrofit’s risk and cost; while increasing the repeatability of this design to similar types of DC switchgear. The safety of the operators and maintainers was the main driver of the design. Additional measures were implemented in the design, to prevent contact of maintenance personnel with 750V circuit, this included: a new type of fuse holder that is operated with the use of a hook stick to allow operators to isolate parts without entering the breaker cell; additional shrouding; and warning labels.

Another aspect of the design was the anti-condensation heating for the DC switchgear. The substation was originally built at a time when the internal environment characteristics of steel buildings were not as well understood as they are today. The steel construction can be susceptible to the formation of condensation, and the condensation can contribute to the electrical flashover. Although the building had been provided with de-humidifiers, additional heating in each breaker was required.

Space constraints inside the circuit breaker were once again an obstacle. Thus, Rail Power Solutions proposed compact dynamic heating elements with a significantly small footprint. In addition, the electrical clearances were improved to eliminate the occurrence of any electrical flashovers.

Following the installation and entering the substation into service, all parties are happy with the result. Although the Godinton incident raised significantly the bar for safety, the design as a prototype was successful in terms of both safety and cost saving, and Network Rail is already considering rolling out a plan to renew the DC switchgear on the network.

“RPS, BAM Nuttall, and Network Rail worked collaboratively and innovatively together – the Dollands Moor Switchgear project was a great success.” Network Rail project manager, Daniel Lea.

Rail Power Solutions is a specialist design and consultancy service for DC electrified railways, undertaking complex multi-disciplinary designs. Established in 2013, Rail Power Solutions has grown rapidly as the leading design consultancy for railway electrification systems, with extensive knowledge and experience in Network Rail, London Underground, London Overground, Docklands Light Railway, Merseyrail and Glasgow Subway.