Following a number of safety incidents and the ORR issuing Improvement Notice I/DTHM/20210729/01, Network Rail is introducing the use of ‘Reminder of Live Exposed (RoLE) equipment’ for when working on 25kV overhead line traction systems.

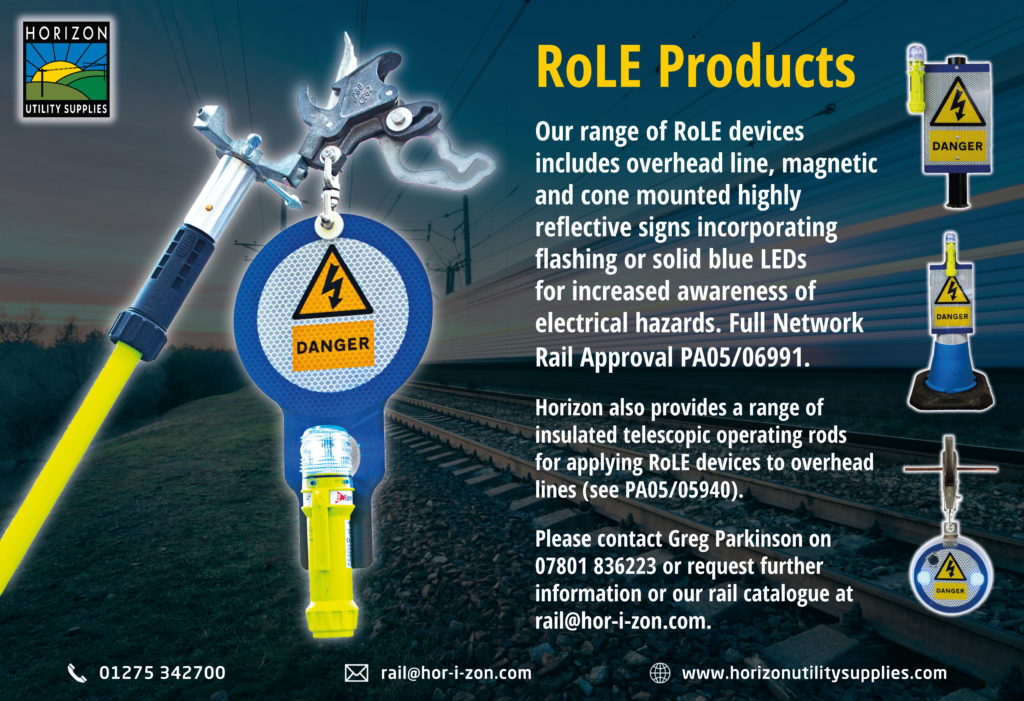

RoLE equipment is simple and consists of a blue steady or flashing light, and a reflective warning sign. Its purpose is to remind staff working on overhead line traction systems to check their Overhead Line Permit (OLP) as they may be approaching their safe working limits, or that a residual electrical hazard may exist. RoLE equipment is an additional procedure to improve compliance with the Electricity at Work Regulations (1989) and to prevent danger and injury.

When working on or near live electrical conductors, the Regulations require that no person shall be engaged in any work activity where danger may arise, unless it is unreasonable in all the circumstances for it to be dead, and that suitable precautions are taken to prevent injury.

The Regulations are mandated by Law and apply to all aspects of the use of electricity within the workplace. Duty holders must have the electrical systems constructed in a way that prevents danger, they must maintain the electrical systems to prevent danger, and any work on the electrical systems must be carried out in a way that prevents danger.

Blue lights

The new requirements are part of standard NR/L3/ELP/29987 Working on or About 25 kV A.C. Electrified Lines and require that only RoLE equipment approved for Overhead Line Equipment (OLE) isolations will be used. Currently, two suppliers of RoLE equipment have been approved and more may follow. The RoLE equipment can be freestanding, attached to the running rail, lineside structures or isolated OLE, and clearly displays ‘Danger’ using a reflective sign. The blue lights are to aid sighting of the warning in darkness or poor visibility, and the use of blue lights ensures that there is no conflict with signal aspects.

In terms of reliability, the blue lights are over specified, but where the lights are not operating the reflective signage is designed to warn individuals of the Safe Working Limits or the Residual Electrical Hazard. When operating, the blue light may be steady or flashing; in both cases the danger meaning is the same to the user. A flashing blue light is normally used, but there may be situations when many RoLE devices are in use, or they may be located near to neighbours of the railway. In these situations, a steady light RoLE may be better.

RoLE equipment has already been in use at some sites for some time and was previously known as ‘Demarcation Equipment’, but it will now be introduced across the network to improve safety. Where RoLE equipment is being used, it will be identified on the Overhead Line Permit (OLP) (Form C). All holders of PTS (AC) and COSS (OLP) have been briefed that: (i) they must receive a briefing of the safe working limits of their OLP (Form C) prior to starting work; (ii) they must also receive a briefing of any residual electrical hazards present within the safe working limits of their OLP (Form C); and (iii) if they don’t understand their safe working limits or residual electrical hazards, they must challenge the Nominated Person or COSS (OLP) delivering the briefing.

Residual electrical hazards

In an ideal situation all the overhead line equipment would be isolated when work takes place, but this is not possible unless it’s Christmas with no trains running, and even then it is not practical to isolate all overhead line traction systems. This is why there will always be residual electrical hazards. Consider a four-track route with Up and Down Slow Lines, and Up and Down Fast Lines.

To keep the railway operational during maintenance it may be necessary to isolate only the Slow Lines, with electric trains still running on the Fast Lines. If the 25kV feed to the Fast Lines runs from the cess side of the Slow Lines then there will be a residual electrical hazard on the Slow Lines overhead equipment from the live cross track feeders.

Examples of Residual electrical Hazards are: live adjacent OLE, including Autotransformer Feeder Systems (ATFs); live cross track feeders; live bare feeders; and live cable sealing ends.

Visibility

When used, the RoLE equipment must be visible from inside the Safe Working Limits on the line it is fitted to and not applied to live OLE, live ATF, or non-earthed return conductors. They can only be installed, moved, inspected and removed by a Nominated Person or Authorised Person, and must not require any personnel to go within 2.75 metres of exposed live parts in order to install, move, inspect, or remove them.

It is also important that they are not placed such that they obstruct or interfere with signal sighting, and an assessment must be made by the Nominated Person if the RoLE equipment is defective. In dual electrified areas they must be installed to the running rail furthest from the conductor rail. When provided, all RoLE equipment must be recorded on all the required paperwork. It must be checked to ensure it is fit for purpose before use and counted ‘in and out’ before and after use.

Planning

During the planning stage of an OLE isolation and as part of the electrical risk assessment, the frequency of inspection of RoLE equipment that is to remain in place for extended periods of time, must be determined. Typically, the normal frequency for inspection shall be every 24 hours. However, the frequency of inspection should be determined based on a range of factors, typically including the duration of work, the length of the site of work, the battery life of the device, and the likelihood of any disturbance.

The selection and location of RoLE equipment is determined as part of the Isolation Details Form completion and the electrical risk assessment for the proposed work. The selection and location details are dependent on the electrical risks related to the work, the work delivery method, the device remaining visible, and the environment in which it is to be installed. For example, a static blue light might be less effective in a junction area with multiple features, therefore it may be decided to use a flashing light.

As a result of mandating the use of RoLE equipment, the following forms have been updated: IDF – Isolation Detail Form, Form B – Authority to test and apply portable earths and RoLE devices to overhead line equipment, including return conductors and autotransformer feeders; STED – Switching Testing and Earthing Detail; and Form C – Overhead Line Permit (OLP).

An important point is that not all residual electrical hazards may be identified with RoLE equipment, and the golden rule for engineers working on 25kV overhead line traction systems is to always, always check the OLP (Form C).