A seminar with a title like ‘High Performing Railways’ just had to be investigated and it was a privilege to be able to participate in the two-day, online event held in early November. With many pre-recorded presentations to listen to and two online question and answer sessions, it was quite a marathon.

Organised as a joint affair between the IET, IMechE, IRSE, IRO, PWI, and RIA, this was effectively a Railway Engineers Forum event. The subject matter covered all disciplines and some unexpected ground. So, what could be considered a high performing railway? Two such lines were cited − the Channel Tunnel Rail Link (HS1) and London Underground’s Victoria Line.

Channel Tunnel Rail Link

Dyan Crowther, Managing Director of HS1, acknowledged that a new line built for a specific purpose should be capable of giving high performance. HS1 is designed for high speed, and all the associated infrastructure is capable of being maintained without disruptive possessions. Blockades should never be necessary as the hours set aside for maintenance and renewals are sacrosanct.

The line can also claim green credentials and aims to be carbon neutral by 2030, partially by removing most flights to Paris and Brussels. Although a serious downturn in business has occurred because of Covid, the road to recovery is underway which includes merging Eurostar with Thalys to create GreenSpeed, an integrated high-speed network for Northern Europe.

Victoria Line

The Victoria Line opened in 1968 and was the first application of Automatic Train Operation (ATO) with a 90 second headway between trains. By the 1990s, the technology’s obsolescence meant an upgrade was necessary, resulting in a new fleet of trains and a ‘distance to go’ radio control system. This has yielded a capacity increase to 36 trains per hour in the peak, according to Charles Horsey from Transport for London, making it one of Europe’s highest performing metro lines.

Alongside all this, there is the need for minimum station dwell times, terminal station management, good information systems with local accountability, crew utilisation, and the ability to quickly recover from perturbations. Advancement of the technology is continuing with timetable design being critical. Trains make 500 round trips every day amounting to eight million per year for the entire fleet.

Operations management

Some basic guidelines on how to predict and manage operations were given by Felix Schmid, Professor emeritus from University of Birmingham. Fares and tariffs are easy to change whereas infrastructure alterations and resource restructuring are difficult and expensive. Timetables are often heavily politicised but are cheap to amend providing the assets, rolling stock and staffing are commensurable. New lines, changed layouts, and new signalling systems carry huge risk. Variety is the enemy of performance and performance is the enemy of variety.

Single line railways offer poor capacity and performance – many routes in the UK were reduced to a single track in the 1970s-1980s and were subsequently re-doubled at considerable expense. Double track is better but still restricted if it is a mixed traffic railway. Metros offer the best capacity where all trains do the same thing. High Speed lines are similar but are limited by braking distance between trains. Flighting of services offers the best compromise.

Performance

Performance issues were discussed by Steven Brown from Rail Aspects. A recent survey of customers showed that punctuality and reliability were the top priority. Delays and how they are dealt with are the biggest source of dissatisfaction. One UK train operating company’s data showed that with a revenue of £800 million, the cost of delays was £145 million with ‘delay repay’ costing another £5 million, a significant worsening of the finances. Cancelling a single train costs around £5,300 amounting to £1.47 billion for all cancellations annually.

Performance has worsened over the period 2014-19. Train running must match the advertised timetable, realising that one train being delayed will cause delay to other trains. Modelling can help but beware of overestimating the value of the model: rubbish in = rubbish out!

The key is to have rolling stock and train crew numbers that match the timetable, but too many crew changes en-route will cause disruption. Strangely, adding one minute to the timetable is more acceptable than having one minute of delay but following this premise may result in journey times that are worse than in steam days.

Systems engineering

This term is still something of a mystery. Anne O’Neil and Bruce Elliott from Cap Gemini attempted to explain. The ‘System’ will have many sub-systems and these must integrate into the whole system. Specify the outcomes, not the assets but define the capability and functionality. Technical changes are not the solution to the end requirement. Emergent scenarios need modelling and simulation, but these must be well focussed. Many tools are available – VISION, OSLO, RAILSYS, TRAIL – that focus on different specialisms. Increasingly dominant are BIM and Model Based Systems Engineering (MBSE). All these can be viewed online for suitability. A good example of Systems thinking was the London Underground Circle Line where to improve reliability, it was changed to a linear line with two end stations yielding an integrated fares and information structure.

Systems Engineering requires a ‘Line of Sight’ which can be described as Purpose > Operational Concept > Whole System Design > Disciplines and Sub Systems. In Engineer’s speak, this might be better described as Determine > Develop > Design > Deliver > Display. A little disappointing in this presentation was no mention of where ‘The Directing Mind’ sits, nor any reference to Digital Twins that has emerged as the optimum way of ensuring a trouble-free system development.

Reliability engineering

Nigel Best, Systems Analysis Manager at Network Rail, spoke about measuring trends in train service reliability. After seven years of reasonable stability, the Covid pandemic has led to improved reliability as fewer trains are running. High performance means value for money, reliability of the end-to-end journey, adequate capacity, safety and sustainability, and above all reliability of the infrastructure assets and rolling stock.

Performance requirements start with the business case, then the functional and operational elements to meet this, and finally the asset and technical aspects. A feedback loop between all of these is necessary noting that different criteria are needed for new or existing railways. RAM starts by constructing the V Diagram life cycle but now includes PRAMS (Performance, Reliability, Availability, Maintainability and Safety) to include supplier engagement.

Modelling the likely outcome of failures using data from a past year’s operation is recommended. Modelling is ideally geared to a 15-year future majoring on control room operation with all other functions − signalling, rolling stock, power and suchlike − linking into that. Failure mode analysis as to frequency, response, effect, system fault tolerance, criticality, and control decisions, are all part of the modelling assessment.

Using technology and associated processes to improve reliability was considered by Oliver Bratton, the Director for Network Strategy and Operations at Network Rail. Computer controlled railways have the best reliability with a fully automated railway giving optimum performance – easy in the Metro sector but main lines and especially mixed traffic lines being more difficult.

He posed the question, how do you know what signals are showing red on the network, currently, in 60 seconds, in 60 minutes or in a whole day? Factors like asset failures, route and speed restrictions, weather, make this prediction very difficult. Driver behaviour, train length, freight train movements, passenger loading times, all contribute to the equation. Planning a timetable is not easy and built-in recovery times are not always beneficial as they sometimes do not relate to where the problems are. Only with accurate data and intelligence within the system can data be analysed to improve reliability.

Train braking and adhesion

The performance and reliability of modern trains is impressive, but a crucial factor is an effective braking performance. With higher speeds, braking distances increase and capacity decreases. It is all about kinetic energy so says Daniel Woodland, a Principal Consultant at Ricardo and immediate past President of the IRSE. Braking converts energy into electricity or heat which must provide an adequate force to stop a train.

Various forms of braking exist, including: tread or disc brakes which can damage wheels or rims; dynamic brakes that produce electricity by turning train motors into generators; hydrodynamic brakes that provide energy into the drive shaft hydraulics; flywheel activation where the energy is absorbed by the flywheel; rubber tyre wheels alongside the steel wheels which produce greater adhesion; magnetic track brakes that attract the train to the rails; and eddy current brakes that do much the same thing.

Of these, dynamic brakes are less effective than friction brakes, being ineffective at low speed and slow to activate. Adhesion will vary due to conditions – water, grease, ice, leaves, vegetation – which may be improved by sanding, plasma torches, water jets, scrubbers, or chemical enhancers. The recent Salisbury accident is a timely reminder. Consideration must also be given to acceleration and jerk rates that can impact on passenger comfort. Eliminating adhesion-free braking can result in a 20% capacity improvement.

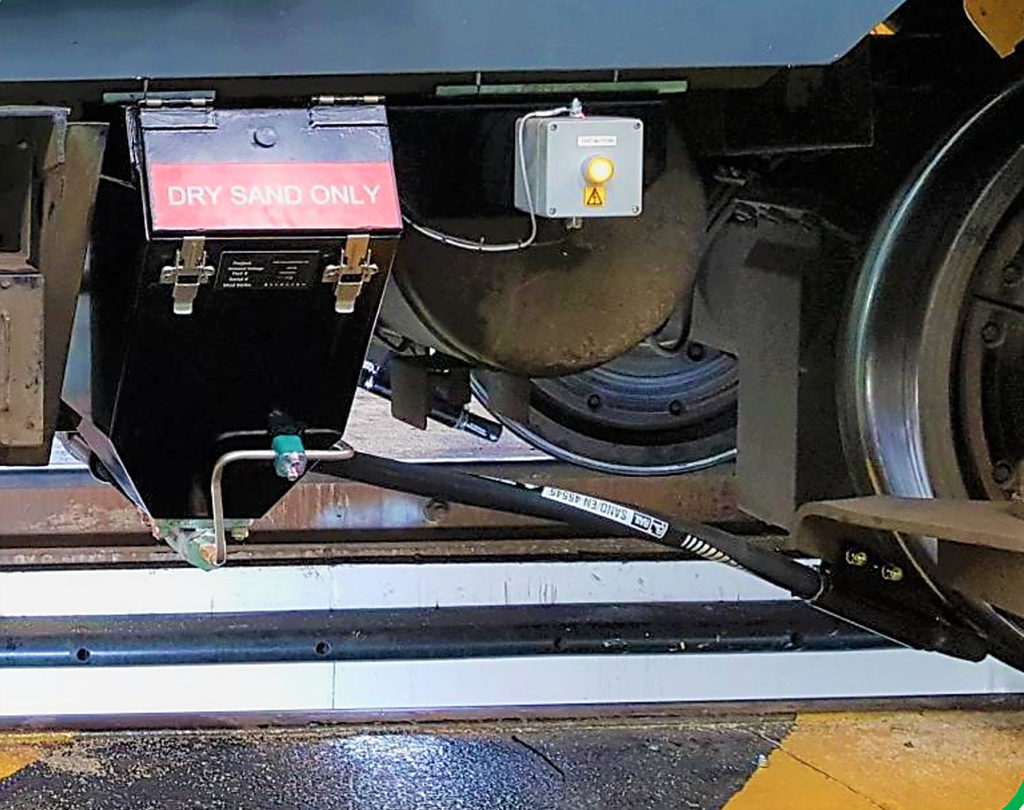

Optimum sander configurations

The cost of adhesion problems is around £345 million per year, according to Liam Purcell from Ricardo Rail, mainly in delay minute payments and remedial work. Sanding equipment is commonly used but is its efficiency always maximised? Application of sand can be either automatic or driver initiated, typically dropping 2kg/minute/rail on the third wheelset. By developing variable rates of application up to 7.5kg/minute, dependent on speed, improvements of up to 50% less distance travelled during braking have been witnessed at a Network Rail test track.

Applying sand to the third and seventh wheelsets brings further improvement to stopping distances and, as the time the sand is applied is reduced, so the usage rates are not changed significantly. Beware, however of applying too much sand at low speeds as this can impact on track circuit operation.

Infrastructure data

The need for data to aid reliability has been stressed but understanding the data is a problem according to Jeremy Allen from Cognisant. Data requires clever computers to interpret and handle it. The roll out of intelligent infrastructure on Network Rail is yielding information on the probability of single asset failures, when failures will occur, the impact of the failure, and planning an intervention prior to a disruption occurring. Such data has already avoided 1.3 million hours of manual maintenance, 500,000 minutes of passenger delay avoidance, a 10% reduction in service affecting failures, and improved safety at the lineside.

Data, in itself, has only limited value and needs to be surrounded by the right people and technology. Of the latter, drones and helicopters for airborne surveying, along with with forward facing imaging from trains, are creating a 3D digital map for lineside inspections. This builds a ‘data lake’ which needs artificial intelligence to successfully interpret it and provide the right decisions for humans to action.

Decarbonisation and electrification

A high performing railway is usually electrified but does not have to be. David Clarke, the Technical Director at the Railway Industry Association, gave the UK statistics. While 70% of trains are electric, only 40% of the route mileage is electrified and, for freight, only 10% of trains are electrically hauled. Both statistics are way behind mainland Europe. So why is this? The boom-and-bust approach to electrification in past years has not helped with insufficient skills being available for the GW and Edinburgh Glasgow projects with consequential cost escalations and delay. The result was electrification investment being cut back.

The RIA wants to see a rolling programme to get 60% of the network electrified to meet the England/Wales target of achieving net zero carbon emissions by 2040 (Scotland aims for 2035). Ideally, the aim is to have 90% of the network electrified but is this realistic or affordable? Other non-polluting traction options – battery and hydrogen – are developing at a rapid pace, but these are not yet foreseen as alternatives to diesel for heavy haulage, be it by road or rail. Low volume, passenger-only lines may be more applicable for battery trains. The range and charge times are constantly improving for electric cars and technology transfer should be possible.

Another aspect of decarbonisation is non-traction elements. Eighty-seven percent of greenhouse gases are caused by road transport with only 1.4% relating to rail, according to Dr John Rossa from Network Rail. However, the railways must not be complacent if the national target of net zero by 2050 is to be achieved. Network Rail has 8,500 road vehicles which need to be replaced with electric technology incorporating telematic intelligence to reduce mileage. Electricity needs to be provided by 100% renewable sources with power purchase agreements that allow feed back into the grid; devices in depots and offices need to be energy efficient; hydrotreated vegetable oil (HVO) is required fuel for generators and plant; charging points are needed in station car parks. All of this requires capital spend but also an understanding of carbon emissions within that spend.

System Design

While good design is part of a high performing railway, performance can deviate from what is expected. Alex McGrath from Melbourne, Australia asked: “Does this matter and how can it be measured?” Her experience of local railways showed design deviations in engineering, operations and resources. People must; i) recognise the change; ii) decide what to do next; iii) consider who to ask; and iv) establish a full information flow within the organisation.

Two examples were cited. Pedestrian level crossings have a hierarchy of controls, but users frequently disobey lights and gates, particularly if they notice a train stopped in a station. Therefore, the design is flawed. Power supplies range from a mix of safety critical to essential commercial. Duplication of grid supply points, often with a battery back-up, do not always provide the robustness desired. A rail control centre (ROC) should be the nerve centre for infrastructure, rolling stock, and all aspects of operation, maintenance, and emergencies. Evidence suggests they often struggle to adjust to more trains, layout changes, and timetable amendments. Design is part of this and, whilst failures will occur, having a nimble recovery plan is essential.

Power supplies

A robust power source is essential for any high performing railway. The existing system for 25kV overhead catenaries has static imbalance with special transformers needed to combat low frequency harmonics, a maximum rating for peak power, a low power factor at low loads, and the requirement for neutral sections. Power is taken from 275kV or 400kV HV grid connections at the feeder stations.

Dr Dela Sharifi from Atkins has researched Power Converter Feeder Stations enabling fully synchronisation with each other by active voltage and phase control. Neutral sections are eliminated, and all power sources are effectively joined together. Further, the power feed can come from any convenient grid line, be it 132kV or even 33kV with trains taking proportional power according to the distance from the power source. A study of 14 trains (seven in each direction) over a 160km section demonstrated that by using this system, the transmission losses were reduced if the number of feeder points were increased from convenient grid lines. This is being promoted for newly electrified lines as it has lower capital costs. The configuration for existing lines needs more research as to practicality and cost.

Point machine reliability

Point actuator mechanisms are a common cause of failure. Anna Cornish from Voestalpine informed the audience that, on London Underground, 67% of points are pneumatic but only 0.2% are monitored, whereas 28% have point motors with 45% monitored. The latter are invariably the Siemens M63 Surelock, the latest ones having current draw and temperature sensors. Current monitoring can be applied to older machines and to the few clamp locks that exist. The ongoing policy is to fit data loggers wired to local servers and then over radio to a control centre. For the future, intelligent switch machines will emerge with a built-in, self-monitoring facility, including sensors for rail vibration and hydraulic/pneumatic operation, accelerometers, and the capability of integrating with other monitoring systems.

Track worker safety

Recent fatalities have highlighted the ongoing risks to track workers with higher speed and quieter trains. Nick Millington, Head of the Safety Taskforce at Network Rail and President of the PWI, stated that with the issuing of an Improvement Notice from the ORR, a radical rethink of how to maintain and fault find on operational lines must now happen. Site unawareness and look out failures are prime causes of accidents and near misses so two priorities are being implemented: i) zero use of lookouts; and ii) line blockages to carry out work. Five activities are considered − maintenance reviews, signaller workloads, line blockage data, planning and delivery, track safety technology.

Twenty-eight million maintenance tasks are performed each year on Britain’s railways. All are being reviewed with some no longer being needed and more use made of risk-based periodicity. Intelligent infrastructure and condition monitoring with plain line pattern recognition being carried out by monitoring trains, all enable remote based inspection. New technology is continually being developed − drones, a geofence to provide a virtual wall around a safe space, and train operated warning equipment. More access points and safer walkways have reduced slips, trips and falls. The use of unassisted lookouts and lookout-operated warning systems will be phased out. The roles of COSS and Site Supervisor will be merged. Health and wellbeing of staff will result in medicals every three years.

However, routine maintenance and fault rectification will still be needed. Line blockages will be necessary for the former and windows of 15 minutes with trains stopped will be granted once the technicians have assessed a faulting requirement. Failure to achieve a clearance in that time will mean coming away from running lines with a re-think on the work needed, and another 15-minute blockage will be requested. Liaison with signallers will be crucial. An integrated access system linking into the signalling system is being considered. Work in the cess is to be discouraged but will be allowed providing a two-metre distance from a running line can be guaranteed.

Standards

How do standards impact on a high performing railway? Tom Lee and Dan Hamm from the RSSB stated that standards represent a common way of doing things, providing interface requirements for linkage of systems and ensuring hazards can be considered appropriately. Some are market led, to avoid the risk of proliferation when competing innovations emerge. Standards must not stifle innovation, but a resulting standard should be of benefit. Standards should not be blindly followed if they are inappropriate or cause a cost increase. Challenges to standards are always welcome.

A classic example has been the introduction of multi-mode rolling stock where many technical and operational issues emerged, namely: changeover from one mode to another by automation or the driver, on the move or when the train is static; maintenance routines; who is involved – TOC, rolling stock owner, manufacturer, infrastructure manager. The resulting standard became a framework for collaboration that has led to a general acceptance.

Climate conditions

A high performing railway must be resilient to climatic conditions. With the recent world summit in Glasgow fresh in our minds, what does climate change mean for the railways? Andrew Quinn from University of Birmingham observed that the focus is predominantly on carbon emissions but much less on the impact for infrastructure and operations. Infrastructure varies enormously according to its age and the design standards of the day, also geographical distribution and its sensitivity to variables. The vulnerability is insufficiently known as to the weaknesses and risk.

Caroline Davies from the Met Office said that much time is being spent on forecasting techniques in terms of current time, hours, days, weeks, months, and seasons ahead. Probability predictions will include financial impact which presently is based on intuitive thinking. Longer term predictions are less accurate, but patterns do exist for 30 different kinds of weather dating back to the 1850s. Turning predictions into useful information for transport is a challenge and a three-month forecast is the aim.

For rail, three outcomes are considered: i) robustness so that the infrastructure does not fail; ii) redundancy where alternative services will be available; and iii) recovery with a plan for rapid return to service. Planning and asset management processes are needed for each eventuality. Identification of hazards and weak assets is important to identify the vulnerability of these and produce train service plans that mitigate the risk. One can only hope that HS2 planners are taking climate into account.

Water ingress and flooding are high risk. Prof John Dora gave a quote from Thomas Telford: “flooding is the Civil Engineer’s greatest enemy”. With railways traditionally built along river valleys and often across flood plains, they are particularly vulnerable. Modern signalling technology has made the problems worse with cables and equipment at ground level, compared to high up telegraph poles and wires in the past. Rainfall, surface water, ice melt, storm and tide surges, coastal erosion are all making the risk of flooding more likely.

How to deal with this has no easy answer but three considerations emerge: i) by design for new and refurbished assets; ii) by maintenance meaning understanding the thresholds and keeping drains clear; and iii) by operational measures on the assumption that floods will occur with associated reaction analysis and good forecasting. Technology can play its part with improved alarm systems that monitor bridge scour, rock falls, landslips, and water levels.

In summary

This seminar covered a lot of ground. A high performing railway is not about high-speed lines or high-capacity metros. It is about every line and route in the country. Making all of these high performing is the challenge for engineers and operators, and the seminar gave useful guidance as to how this can be achieved in all disciplines. If this article awakens people to the issues, it will have achieved something.