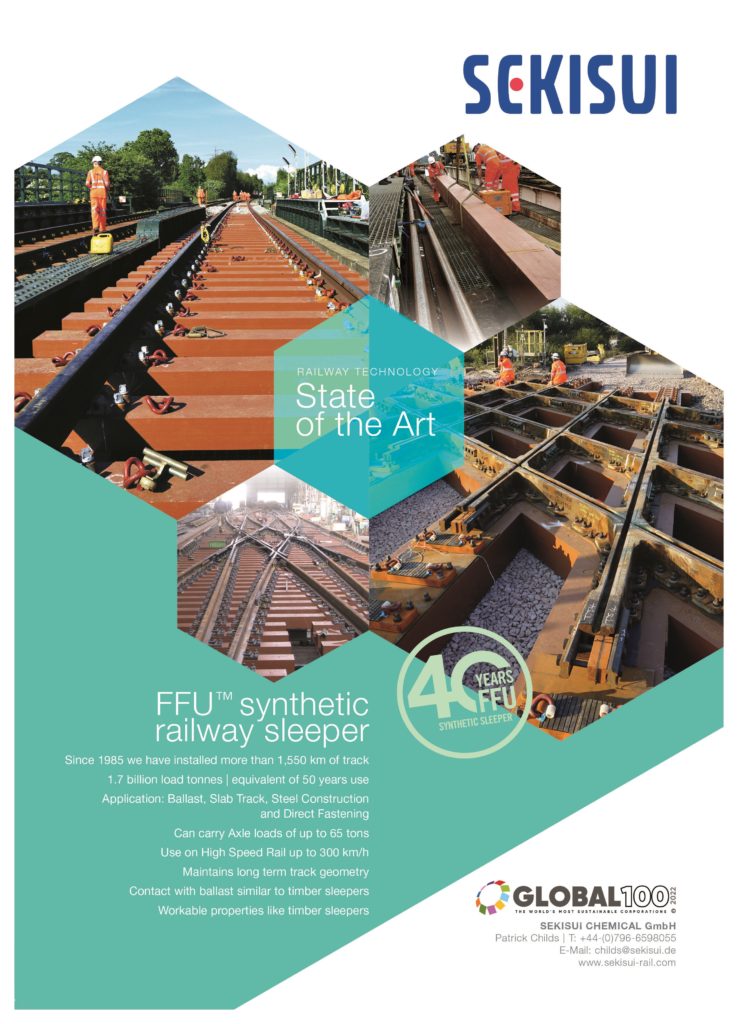

In Issue 193 (Nov/Dec 2021), Rail Engineer looked at Sekisui’s fibre-reinforced foamed urethane (FFU) railway sleepers, which are seeing increased usage across Europe and are due to be installed on the UK’s Chelsea River Bridge. With the same weight as natural wood, and with many of the same properties, FFU is easy to repair and has an extremely long life, and it’s easy to see why this technology is now seeing more widespread use. However, FFU timber also has many environmental benefits which should not be overlooked.

A long life

Synthetic sleepers are not a new phenomenon. Sekisui began developing its product in the 1970s and the first FFU sleepers were put into use on Japanese railway in 1980. Remarkably, since then none of the originally laid sleepers have required removal or replacement.

In 1996, Japan’s Railway Technical Research Institute (RTRI) carried out tests on sleepers which had been installed in 1980. Several fatigue tests were conducted simulating 100 million load cycles. These tests led to the prediction that FFU would have a life expectancy of 50 years. In 2011, sleepers from 1980, which had now been in service for 30 years, were again removed and tested by RTRI. As a result, RTRI confirmed that these FFU sleepers would work safely for the next 20 years – taking their total useful life to 50 years.

One reason for its longevity is that FFU is not affected by UV light and retains its technical properties after many years of exposure. Where FFU is not painted, long-term UV irradiation only leads to discolouration of the surface. Not only does this increase the material’s durability but also has environmental implications as FFU products do not need to be treated with harmful chemicals to protect them from UV exposure.

Sustainable and recyclable

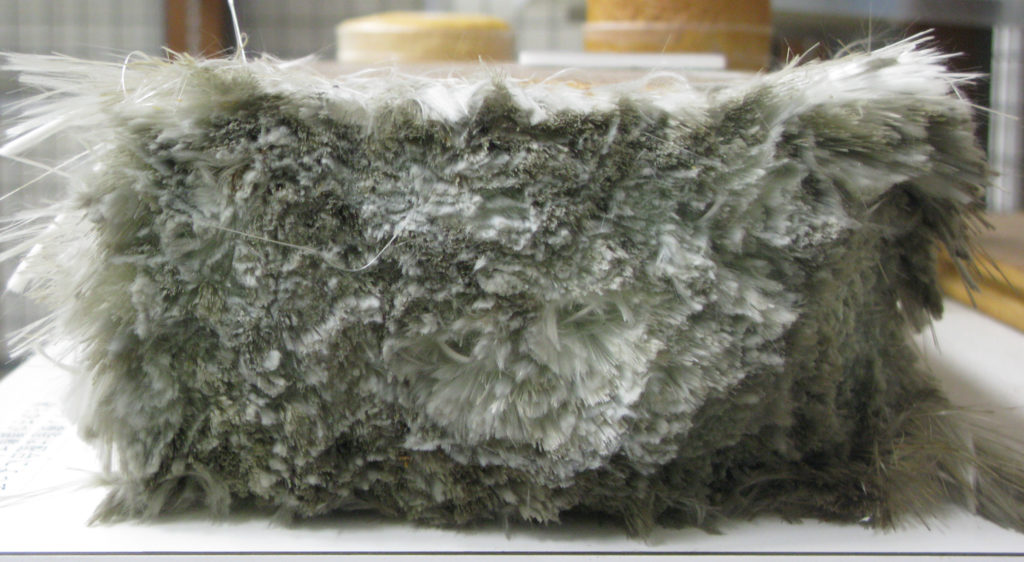

Sekisui’s synthetic sleepers are manufactured using the ‘pultrusion process’ in which glass fibres are soaked and mixed with polyurethane, then hardened at a raised temperature, moulded, and cut to length. The only waste from this process comes in the form of waste dust and chippings from drilling, milling, and sanding, and 100% of this waste is recycled. For example, FFU in the form of so-called K-FFU, is made from manufacturing waste, and has been used in Austria and Germany as sole-plates in bridge abutment wall bearings with a constructive height of a few millimetres.

In addition, all synthetic wooden sleepers are recycled at the end of their lifetime and new products are created from them. At the end of its life on the track, FFU can be reused in a number of ways. For example, it can be cut down to size for other projects; used for level crossing deck material; used as walk board on pedestrian bridges; or returned to Sekisui who will use it to produce further products. The company already produces numerous products from production waste including Anker plates, FFU sheets for other industrial applications, and thin FFU plates using FFU dust.

The use of recycled sleepers reduces greenhouse gas emissions from sleeper production and puts recycled plastic back within the track infrastructure for at least 50 years.

Award winning

Sekisui’s environmental credentials have been recognised by industry bodies, globally. In early March, the company received the Bronze Award at the third ESG Finance Awards in Japan, hosted by the country’s Ministry of the Environment. Sekisui took the award in the Environmentally Sustainable Company category and was recognized for integrating environmental issues into its business strategy, its high awareness of environmental issues in promoting (ESG) management, and its planning and implementation of an environmental medium-term plan.

In February, Sekisui was given a “Silver Class” sustainability ranking by S&P Global, a global ESG investment investigation and ranking company, and in January it was selected as one of the 2022 Global 100 Most Sustainable Corporations in the World, by Corporate Knights Inc. The Canadian company recognised Sekisui’s efforts towards a sustainable business based on environment, society, and governance.

Sekisui has also been selected for 10 consecutive years by the World Index of the Dow Jones Sustainability Indices (DJSI) and has attained the highest rank in the Development Bank of Japan’s Environmentally Rated Loan Program, in recognition of its environmentally conscious initiatives.

Safety on the tracks

But a product is not sold on its environmental record alone. FFU timber is a high-quality substitute for timber. Being a closed cell structure, FFU does not absorb water and is also chemically resistant to oils, lubricants, and pollutants. Essentially, it has the same properties as wood but does not deteriorate over time.

Experience with a wide variety of synthetic sleepers has shown the railway sector that the various technologies on offer differ considerably in terms of quality, technical characteristics, and the behaviour of the materials used. For this reason, by classifying the materials into types, operators of rail networks in many countries have presented these differences in a manner that is practical for the ISO Standard 12856-1 (2014) for synthetic sleepers.

As those responsible for the rail networks are aware, these differences are evident when it comes to procurement and, much more importantly, when it comes to the safety of daily rail operations, in technical longevity, reliability, and therefore also in the availability of the track systems.

Many of the technologies presented to the operators of rail networks thus far have hardly any reference points in railway tracks, and they only have temporary approvals for testing purposes, based on the results of laboratory tests.

Industry proven

Fibre-reinforced foamed urethane (FFU) synthetic wood sleepers have been in continuous operation on rail networks for over 42 years. Since debuting in Japan, FFU sleepers have been used by the Vienna public transport system, Wiener Linien, on the Wienfluß Bridge project; on light rail networks in Hamburg, Berlin, Düsseldorf, München, Bochum and Toulouse; on the London Underground; and on the Paris and Lille metros.

Among the products available on the market today, Sekisui’s FFU timber possesses the highest number of positive characteristics, determined in laboratory examinations and test results. The patented construction of its glass fibre strands guarantees the highest level of safety and reliability in daily use on railway tracks. In countries across the globe, FFU synthetic wood sets the standard for use as synthetic railway sleepers on bridges, in points, and in tunnels.

FFU synthetic sleeper technology simply performs.

Photo credits: Gunther Koller