The class 168 and class 170/171 (hereinafter class 170) ‘Turbostar’ diesel mechanical multiple units were built between 1998 and 2005. In railway terms these trains might be described as being halfway through their lives. But in terms of diesel engine technology and environmental knowledge a lot has happened that now renders their diesel engines highly undesirable.

1998 was around the time that diesel engines for cars were being encouraged as environmentally friendly because they produced less carbon dioxide than the equivalent petrol engines. Indeed, at the time, diesel fuel was cheaper than petrol for road use. Subsequently, as is well known, oxides of nitrogen and fine particulates, a significant by-product of diesel engines, were recognised as serious polluters.

Reducing these pollutants became important. Clearly, electrification is the best solution with no emissions at point of use, but this will take many years to complete, and there will never be an economic case for electrification on some routes where, ideally, battery or hydrogen-battery power might deliver emissions free solutions.

In the meantime, how might emissions be reduced from the existing diesel trains? At the 2015 Railtex exhibition, diesel engine company MTU (a division of Rolls Royce) displayed a diesel/battery hybrid raft that could be retrofitted under existing trains. This was exhibited again at Railtex in 2019. At the 2019 exhibition MTU stated that they had been testing hybrid drives in mainland Europe and had achieved fuel savings of between 15 and 25%, adding that they were working with UK leasing company Porterbrook with a view to “trialling this hybrid drive on a Class 170 DMU next year.”

Following the inevitable impact of the Covid pandemic in 2020, it was in May 2021 that Porterbrook reported on tests carried out at the Ecclesbourne Valley Railway in Derbyshire with the prototype installation fitted to a 2-car Chiltern Class 168/3 unit. And, in July 2021, to celebrate Chiltern Railways’ 25th anniversary, the prototype was used to carry a number of invited guests to Bicester for a celebration lunch. The unit achieved speeds of up to 100mph during this demonstration run and operated with emission free battery power into/out of Marylebone and Bicester. The converted train is expected to reduce CO2 by up to 25%, nitrous oxide by up to 70%, particulates by up to 90% and fuel consumption by up to 25%. There was also an expectation that engine noise level will be reduced by 75%.

On 10 February 2022, the train, branded HybridFLEX, carried its first fare paying passengers and Rail Engineer was there for the event. On arrival at Marylebone station, one is immediately reminded that this is the last London terminus to be served by an entirely diesel fleet. There was significant background noise from idling diesel engines on the classes 165/168 multiple units and a class 68 locomotive with a slight whiff of diesel exhaust in the air. The noise and emissions are of great concern to Marylebone station’s neighbours, a point made strongly by the Westminster City Council member attending the event.

After watching several trains depart accompanied by the characteristic roar from revving engines, two-car unit number 168 329 glided almost silently into the station, illustrating one the benefits of the hybrid drive; quiet and emissions free arrival and departure from stations. Birmingham New Street customers will be envious.

The press launch was introduced by Richard Allen, managing director of Chiltern Railways. He paid tribute to four years hard work by Chiltern staff and their partners – train owner, Porterbrook, Rolls Royce Power Systems, and Gemini Rail Group – and hoped that this development would be a significant part of Chiltern’s modernisation programme for the 2020s. His points were echoed by representatives from the DfT, Westminster City Council, Porterbrook, and Rolls Royce Power Systems.

The conversion

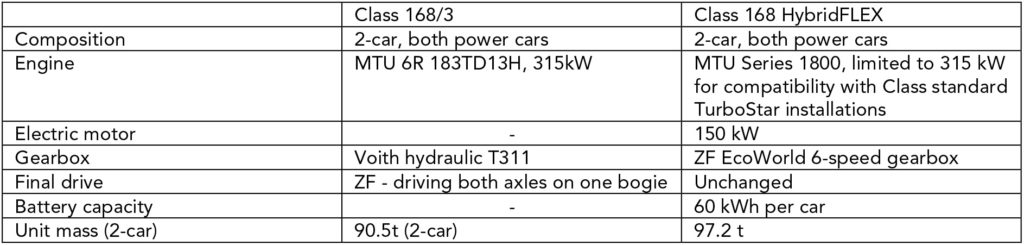

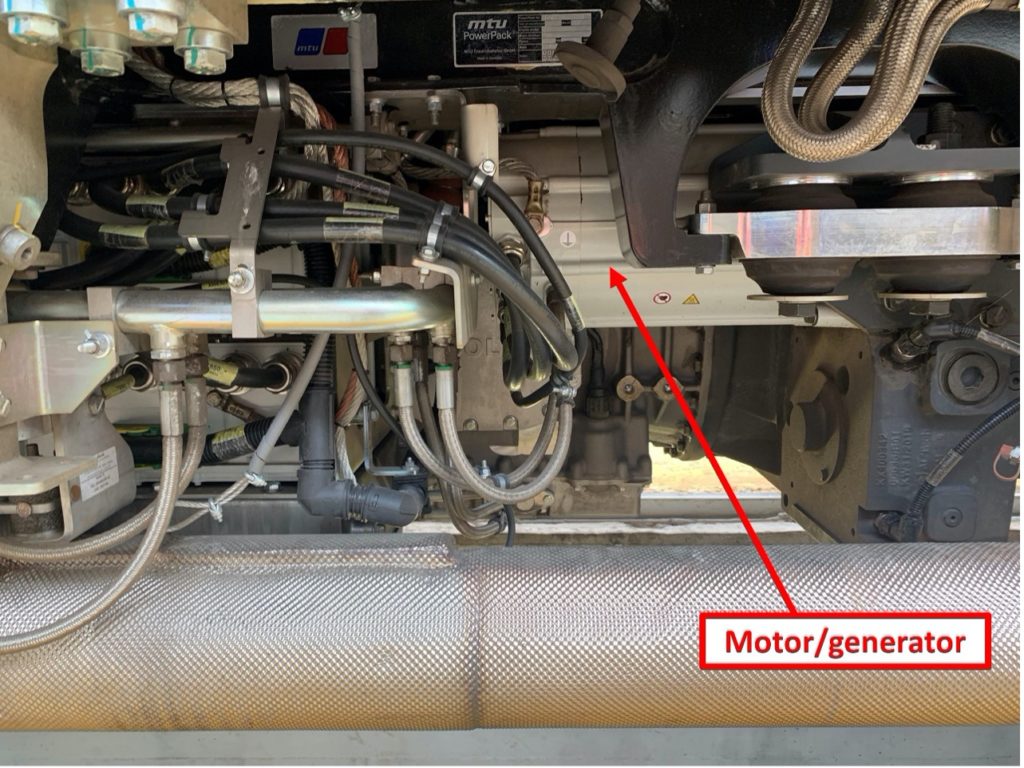

The existing MTU engine, Voith gearbox, hydrostatic ancillary power system, and alternator, had to be removed and space cleared for a new MTU engine, ZF gearbox, and the battery packs. The accompanying illustrations show the new equipment layouts, and the table highlights the key existing and new parts.

The braking system had to be modified to enable dynamic as well as friction braking with smooth transition between the braking systems. Like electric trains with regenerative braking, this operates entirely in the background without the driver having to choose the braking mode.

In addition, for drivers who use the brake cylinder gauge as a reminder of the brake rate applied, a decelerometer has been fitted in the cabs. A new type of driver assistance system, the MTU Intelligent Drive Manager, is being used on this train for the first time. It ensures that the drive system automatically switches off the diesel engines and operates in all-electric mode in areas such as cities or stations which are sensitive to noise or emissions; provided of course that the battery is sufficiently charged. Porterbrook’s Kevin Bilby observed that there is an extra complication as the six-speed transmission is between the final drive and the electrical machine harvesting power; a challenge that no EMU has to face.

Kevin added that electrical power for train control and ‘hotel loads’ is now derived from a solid-state auxiliary converter driven from the battery – or diesel engine via the electrical machine – in place of the previous mechanically driven alternator. This allows hotel loads to be maintained while the unit is waiting in terminus stations. Current practice is to shut down the diesel engines for environmental reasons but that means hotel loads are lost and passengers joining the train before departure are greeted with emergency lighting only. This is particularly noticeable in some stations such as Birmingham New Street.

The proof of the pudding

The key objective of the day was to ride the train and to experience the different characteristics compared with a standard class 170. Anyone familiar with the normal roar as the diesel engine runs up to speed a fraction of a second before a class 170 sets off would have been surprised. The train’s diesel engine was operating, but the departure from Marylebone was smooth and quiet. It was also subjectively quieter than the class 172, which is noticeably quieter than the class 170s.

During the run to the first stop at Harrow-on-the-Hill, the diesel engines stopped with a characteristic thump your writer has experienced on many hybrid buses. This was the only real disturbance to otherwise smooth progress. In fact, the whole journey was smooth and quiet, and it would be hyper-critical to mention the occasional slight jolt during the transition from dynamic brake to friction brake. In conversation, Helen Simpson, Porterbrook’s Innovation and Projects Director said that these issues will be resolved during the service trials with small changes to the controlling software.

Helen paid tribute to the project team whose work was carried out during the difficult times of Covid. As well as main partners mentioned above there were many other suppliers including the certification organisations, Ricardo as Approvals Body, and SNC Lavalin as the Safety Assessment Body.

With the output of the diesel engine and the electric motor combined, each car has a total power greater than that of a standard class 168. Whilst it is currently intended that either the diesel or the electric power sources will propel the train, both can be used in ‘boost’ mode to deliver a noticeable reduction in inter-station run time, although there is a limit that can be accommodated by the retained final drive.

Helen added that the performance is normally restricted so that this unit can work in multiple with other Chiltern units. Boost mode increases acceleration, and Chiltern drivers have been trained in its use. The driver training requirement which Chiltern had carried out was quite significant for just one unit even though the unit will mainly be restricted to the Marylebone-Aylesbury route as Chiltern want to ensure that any driver on this route can operate the unit.

Fleet implementation?

For the future, Helen said once the train demonstrates the forecast savings the business case can be built for the conversion of the entire class 168/170 fleet of more than 450 cars, all powered. Developing a compelling business case is unlikely to be straightforward. Currently, the environmental benefits, although welcome, are not valued in business cases, and the direct fuel saving is insufficient benefit to offset the cost of the conversion. There might be project cost savings to be had by scheduling the conversion when powertrain overhaul would otherwise be due, thus saving the overhaul cost. And there might be benefits from the better acceleration of the trains.

That said, the DfT representative, Jim Richards – Passenger Services Markets Director (South) emphasised the importance of the UK railway playing its part in reducing rail’s environmental impact. He added that reducing environmental impact is a key objective for the new Chiltern contract.

Hopefully this project will lead to all the TurboStar generation trains being converted to hybrid operation delivering a major contribution to reducing emissions and improving air quality around major stations.

compressor. PHOTO: LOUIS SCHMANDT/CHILTERN RAILWAYS

Types of hybrid drives

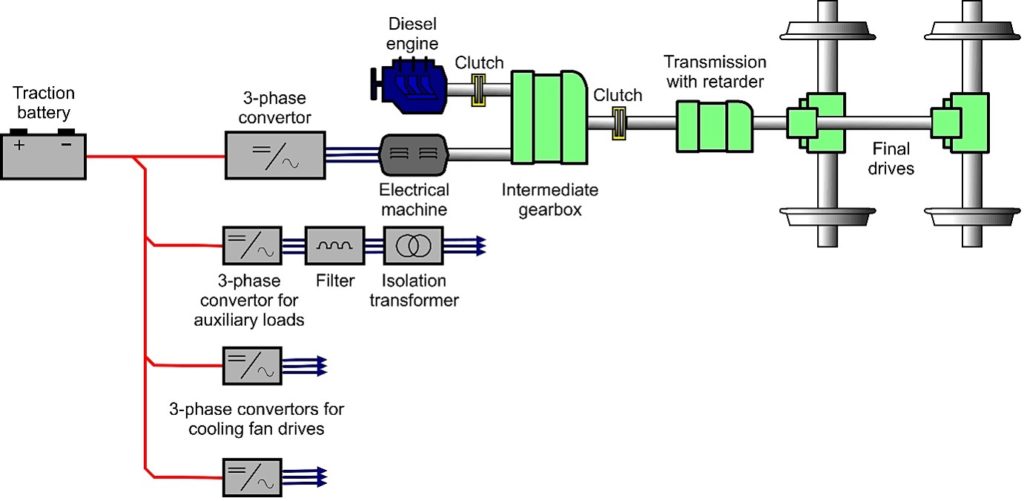

There are various forms of diesel battery hybrid drive trains. In some, known as series hybrids, the diesel engine drives a generator which charges a battery which, in turn drives an electric motor which drives the wheels. In braking, the motor generates electricity which charges the battery. Depending on the state of charge, the diesel engine might run at its most efficient setting to charge the battery or might be switched off.

The HybridFLEX unit, fitted to the class 170, is a self-charging diesel-battery parallel hybrid. The MTU diesel engine drives the rail wheels through a ZF EcoWorld gearbox and the existing bogie mounted final drive. There is also an electric traction motor connected to the input of the gearbox.

foreground: engine,

background: batteries.

generator

The diesel engine can drive the wheels and the motor (as a generator to charge the battery), or the motor can drive the wheels with the diesel engine disengaged. For best performance, both may drive the gearbox. Using both the diesel engine and electric motor together increases the power available compared with a standard class 168/170 unit. Where required, the engine can be switched off, and the train driven solely from the battery. When braking, the wheels drive the motor via the gearbox to charge the battery.