Network Rail is upgrading the iconic Barmouth Viaduct/Pont Abermaw with the biggest restoration of its history: a £30 million upgrade that will protect the well-loved bridge for generations to come. This is creating huge interest among local communities and their very numerous 2021 staycation tourists.

Historic and unique

Barmouth Viaduct is a single-track, wooden railway viaduct across the estuary of the Afon Mawddach near Barmouth, Wales. It was constructed by the Aberystwyth and Welsh Coast Railway between 1864 and 1867. It is 820 metres long and carries the Cambrian Line between Morfa Mawddach and Barmouth stations. Its 113 spans of 5.8 to 6.2 metres make up the longest timber viaduct in Wales and one of the oldest in regular use in Britain. When built, the bridge included a lift span to pass tall ships, this was later replaced by a steel swing span carried on cast iron cylinders, although this is no longer operational. As well as the railway, the spans also carry a Gwynedd County Council owned path, used by pedestrians as well as cyclists as part of National Cycle Route 8.

At the end of the Nineteenth century, the three fixed and two swing metallic spans and substructures at the north end were installed, and older readers may recall that in the 1980s its timberwork was found to be under attack by teredo marine worms resulting in a six-month closure for replacement of 48 piles and the encasement of pile bases in concrete shrouds. A weight restriction and ban on locomotive hauled trains continued from 1986 until 2005.

The planned restoration

The viaduct is now 157 years old, and its mainly timber construction is again in need of replacement. A replacement bridge was considered, but refurbishment was selected. The three-year programme will restore it, whilst maintaining its appearance and its Grade II* listed status. Both the timberwork and the four steel spans at the north end will be replaced on a like-for-like basis. When the works are completed, the viaduct will retain the current speed restrictions of 20 mph for passenger trains and 10 mph for freight.

Network Rail worked closely with Transport for Wales, Cadw – the Welsh Government’s historic environmental service, Gwynedd County Council and other stakeholders over several years to develop and agree the scope of this project. Network Rail took into account how important Barmouth Viaduct is to the local community and tourists. Barmouth is the third-fastest growing holiday destination in the UK and the viaduct is a local icon, much loved by the local communities and visitors who use it and who enjoy its majestic beauty, striding across the water or mudflats of the estuary. The refurbishment work has been scheduled to run outside of the summer peak, to limit disruption.

Network Rail held online public engagement in June 2020 and a public drop-in event in July 2021, to share information, show the construction methodology animations, and to receive comments and feedback. The local community appreciated that noise and other disruption would be incurred, and that rail travel would be replaced by buses for long periods. However, they understood the necessity for the works, remembering the impact of its temporary closure in the past and very much appreciated the £30 million investment in their iconic bridge.

Gareth Yates, Network Rail’s Project Manager, explained to Rail Engineer that to reduce the public impact of the work, this project will take place over three years, with three shorter full closures of the viaduct, rather than one longer full closure. (In 2020, October-November and in 2021 and 2022, September-December.)

The project began in 2020 and will be completed in 2022. During the blockades a bus replacement service is being provided between Pwllheli and Machynlleth stations, with additional bus services for local school pupils.

The contract for the project was awarded to Alun Griffiths (Contractors) Ltd, who are locally based and are proud to be delivering a project which brings economic, social and transport benefits for the area. Half of their project workforce live in the Barmouth area and the social value benefits to the local economy were assessed using the Welsh Government Community Benefits Tool. This calculated that for every £1 of their contract, the local economy will see a return of £1.95.

Network Rail’s design consultant for the timber elements was Cass Hayward, with Tony Gee and Partners acting as Alun Griffiths’ designer for the steel spans.

Timber replacement in the substructure took place between September to December 2020, including a two-week blockade. Works have continued on this this year from June, with a September-December blockade for replacement of the deck. During 2022, a similar blockade will be used to replace the four steel spans. The first six weeks of this year’s phase saw work through day and night to take advantage of better summer weather. Steve Richardson, Operations Manager at Alun Griffiths, explained that working out in the estuary leaves his team exposed to the elements and that “without a doubt, the wind is our biggest issue”.

Timber replacement in the substructure

Fifty-three of the viaduct’s 565 piles are being replaced above riverbed level, together with 119 diagonal bracings and 102 low level walings. The concrete shrouds around the piles at low level are to be replaced/installed on all piles.

The replacement timber members are FSC-certified greenheart hardwood from Guyana which has proven the most durable timber for marine works such as this and is much more durable than the Douglas Fir and Pitch Pine of the original structure. Greenheart is resistant to sea worm attacks which proved so troublesome in the 1980s. Fortunately, the timber had been advance ordered by Alun Griffiths and was already held in stock in Scotland when flooding in Guyana led to a temporary suspension of exports.

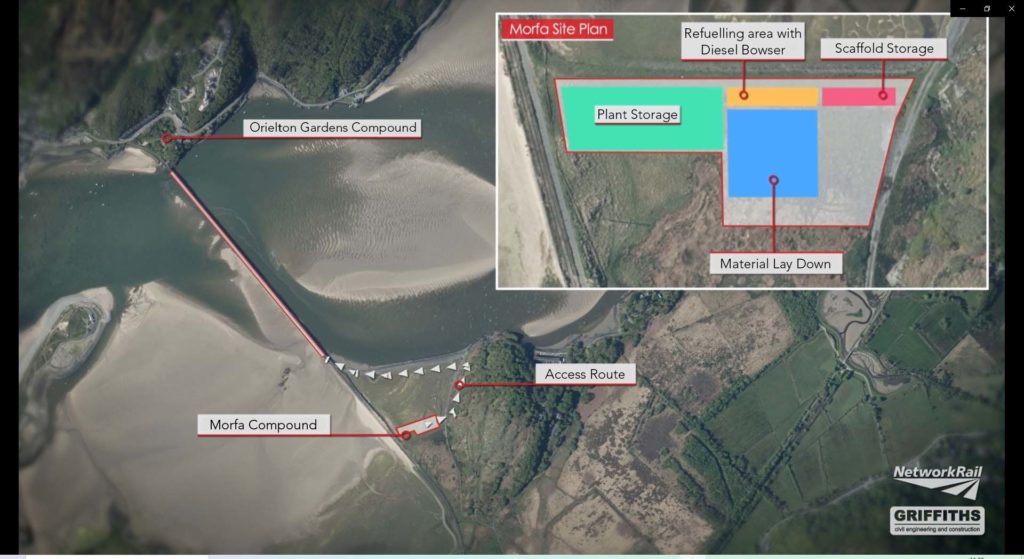

Materials for this part of the works have been delivered by road to the compound to the north of Barmouth and are being taken to site on rail trailers or on pontoons via the harbour.

Much of the timber substructure work has been undertaken at low tide from the riverbed, works towards the main channel being carried out at spring tides with shallower locations being targeted at neap tides. Between four and six hours of work has been possible in each tidal window, calling for careful planning and organisation to maximise production.

At each trestle, the extent of works varies according to the condition of the existing members. The low level walings are first removed and the diagonal bracing members replaced. Next, one bracing is removed and a trestle pile released from the other. The pile is cut off at low level after any concrete shroud has been removed and lifted out by chain hoist supported by a tracked excavator. The remaining stump is prepared to form a half-lap joint to match the previously prepared replacement. The new pile is then placed and bolted up to the stump, the crosshead and bracings. Where necessary, the low-level pile preparation work has been carried out by divers working from a service pontoon. Finally, the joint between old and new is encapsulated in a concrete shroud formed within a GRP former.

The deck beams are supported by short corbel timbers atop crosshead beams on the trestle piles. 291 of the corbels and 81 crossheads are being replaced. Temporary access scaffolding for the high-level works to replace these has been punched up from the walings, which also provides some temporary propping and stiffening of the trestles as elements are removed and replaced. Where corbels require replacement, temporary brackets in the deck have been used to lift the beams clear before new members are hoisted and secured into place.

In 2020, to replace the trestle crossheads the deck was raised by a travelling rail-mounted gantry that spanned the two affected decks. This year, deck beams have been removed to gain access to the crossheads. The beams are then lowered by chain hoists and the new crossheads lifted into place. The replacement brackets and bolts for all connections are of stainless steel.

Replacement of the timber deck

The track is carried on longitudinal timbers that span between corbels. All 452 of these are to be replaced during this year’s blockade, together with the parapet edge beams. The replacement will also provide the opportunity to create a smoother vertical and horizontal rail alignment.

Work began near the middle of the viaduct, at span 57. The existing rails were removed by TXM’s Monster Cranes. These require no outriggers and so are ideal for use on the deck of this viaduct. The longitudinal timbers, decking and edge beams were also removed by the crane and loaded onto rail trailers. Temporary access decking supported from the trestles was lifted into place from a floating pontoon below.

Next, spans 56 and 58 were also stripped out. Where required, this then allowed corbels on the two piers to be replaced before the new longitudinal beams were brought by rail trailer from the Marine Parade and Morfa compounds. These were placed by the cranes and secured using stainless steel bolts and brackets. This process will continue until December, heading shoreward in both directions.

New operational access footway decking boards are of GRP and installed from the temporary deck below as works proceed.

On the shore approach embankments, concrete ballast boards attached to steel posts will be placed between footpath and the track to allow a full ballast shoulder to be formed. Rails will be placed onto the new longitudinal timbers by the cranes, placing one pair at a time across the viaduct.

Replacing the steel spans

Next year’s blockade will see the replacement of the five steel spans. These have been designed by Tony Gee and Partners to visually replicate the current bridges, although reflecting current design codes. The ‘swing span’ will not be constructed to be movable, but with the agreement of Cadw and Gwynedd County Council, it will retain the existing slew ring and other equipment to retain its historic appearance and the whole viaduct’s Grade II* listing.

The new 40-metre-long steel girders for spans three/four and five will be delivered by rail to the south end. The shorter girders for spans one and two will be delivered by road to the north end.

Ahead of the blockade, the steel cylinder substructures will be grit blasted, repaired and painted, ready to receive the new spans.

The girders for spans three/four and five will be loaded onto rail trolleys and taken to the bridge site. A temporary gantry structure will be in place on top of each permanent girder. These will be jacked down onto the existing substructures, forming a temporary bridge between the existing girders. This will be used to support the old structure as it is demolished and lowered from the gantry onto pontoons on the river. The new girders will then be jacked horizontally into their final locations and their cross girders and decking lifted from pontoons. Finally, the temporary gantry will be dismantled and removed. The two 12-metre land spans will be removed by a land-based crane, and the new girders and floors installed from land. The new rails will be fastened direct to the steel decks with Vipa baseplates.

Barmouth Viaduct is loved by its communities and visitors who greatly appreciate its refurbishment and Network Rail’s commitment to this structure. The Alun Griffiths team delivering these works have managed, and continue to manage, the vast logistical challenges of working on this very long and inaccessible site, along with the weather and tides of this exposed location. At the end of 2022 when the project is completed, the viaduct will have a much-extended life but will look just the same as it always has, which is exactly what the team are planning for.