Britain’s nine light rail systems compare with around 30 in France and 60 in Germany as, historically, Britain has failed to invest in its transport infrastructure. With conventional tram systems typically costing around £50 million per kilometre, the UK will not be able to significantly increase the number of its light rail systems without a radically new approach.

The urban Very Light Rail (VLR) programme is such an approach. It is the result of Coventry City Council approaching WMG (Warwick Manufacturing Group) in 2016 to see if a lightweight tram could be produced using the technology of their Revolution VLR railcar (RVLR). The city also specified that the total cost of its proposed VLR system must not exceed £10 million per kilometre.

WMG then partnered with the Paris-based engineering group INGEROP and its British consultancy, Rendel, to develop the required novel trackform.

On 16 June, the Black Country Innovative Manufacturing Organisation held its first VLR conference in Dudley at the Black Country and Marches Institute of Technology. This is next to the almost complete VLR innovation centre as described in issue 191 (Jul-Aug 2021). The event described the latest VLR system developments including the RVLR, Coventry VLR, and the novel trackform. A full report of this conference and the VLR vehicles will appear in our next issue whilst this focus feature considers the novel trackform.

Utilities

Achieving low-cost light rail track installation is only possible if the number of utility diversions can be significantly reduced. These are required when there is a physical clash between the new light rail line and the buried services. The minimum depth of utilities is 450 mm for telecoms cables, 600 mm for electrical cable, and 750mm for gas and water pipes.

In addition, utility diversions will be required if the utility companies consider that the new line does not give them acceptable access to their utilities. Installing VLR track over buried services will only be acceptable to utility companies if they can treat the track as a normal road.

Utility diversions that cannot be avoided are those required for the programme to install plastic pipes to replace legacy iron and steel pipes that are less resistant ground movement. For this there needs to be collaboration to do the required diversions either before or during the track installation.

VLR trackform

The key requirements of the novel VLR trackform are to minimise utility diversions with utility companies having acceptable access to their services. In addition, it must be capable of being installed at a reasonable rate, support high road vehicle loads on a low-stiffness subgrade, accommodate 15-metre radius curves and cost no more than £2 million per kilometre to install.

At the conference, WMG’s Lead Engineer, Dr Christopher Micallef explained that the trackform has a depth of 300mm and requires a maximum 350mm dig. 153mm of this depth is the 55kg/metre 55G2 profile grooved rail. Its panels can accommodate 600 x 600mm utility access chambers and, in an emergency, can be dug out and replaced 24 hours after utility work has been completed.

Its design supports high loads of 30 MPa (300 bar) on a low-stiffness subgrade of 2.3% CBR (California bearing ratio). The CBR is typically 5% to 50% for sandy soils and only 2% for clay.

The trackform is expected to be installed at the rate of 16 metres per day at an anticipated cost of £2 million per kilometre including excavation of the road surface and embedding the track into the road surface.

Testing and installation

However good the design the new track form and the VLR vehicle, extensive testing of both, as a system, is required before work can start on the Coventry VLR system. In addition to design optimisation, this is needed to obtain the required approvals. Physical testing is shortly to commence at two sites.

At Coventry City Council’s Whitely depot, a trackform is to be installed at an HGV loading bay to provide accelerated real life road vehicle loading of track system. The trackform will be monitored to provide structural monitoring and axle load measurement data. At the VLR National Innovation Centre (VLRNIC) in Dudley, the trackform is to be part of the centre’s 15-metre curve and will be monitored for vibration and loading as the VLR vehicle runs over it as part of an extended test programme.

Instant charge

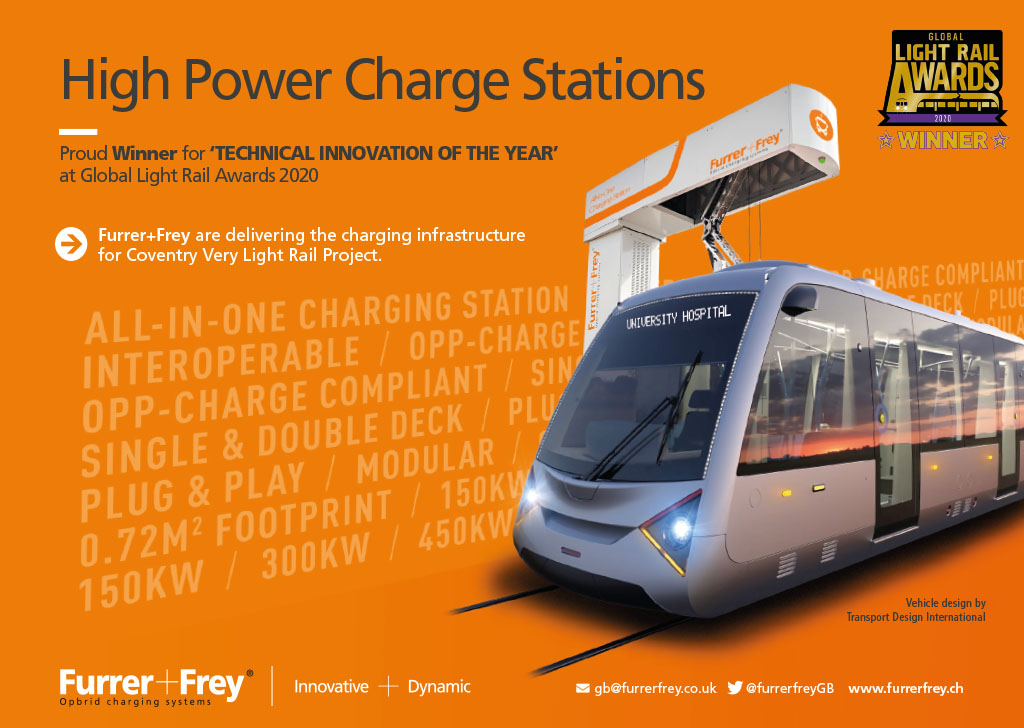

Another aspect of the VLR infrastructure that will be tested at the Dudley VLRNIC is an ultra-rapid battery charging station provided by Furrer+Frey. The company installed its first such charger for battery buses in 2010 in Granada and are now used in Sweden, Spain, and the Netherlands. The charger at Dudley has software developed by Furrer+Frey UK specifically for VLR vehicles and is suitable for charging both VLR vehicles and electric buses. It has an inverted retractable pantograph. Once the VLR vehicle is in place, the charge station automatically tops up its battery. To do so its charging arm with four contact strips, specially designed for high-power transfer, is lowered onto the vehicle’s charging points and energised. This takes less than five seconds. Once the vehicle is charged the arm retracts to a safe de-energised state.

As previously mentioned, it is expected that it will charge VLR vehicles in 3.5 minutes. The unit has a maximum capacity of 475 kW.

The VLR system

Coventry’s VLR network is planned to consist of four loops, the first of which will connect the city’s Washgrave Hospital to the city centre and open in 2026/27. Prior to that, a 1.6km demonstration line between the railway and bus stations is expected to be operational in 2024.

At the conference, it was clear that a significant amount of work has been done to develop the VLR vehicles and their trackform as a complete system. It was also clear that other towns and cities are considering their own VLR systems and that VLR has the potential to significantly improve urban connectivity.